Hot Rolled D-bar with Many Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offeringDeformed Steel Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Product Advantages:

OKorder's Deformed Steel Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Chemical Composition: (Please kindly find our chemistry of our material based on HRB400 as below for your information)

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥400 | ≥570 | ≥14 | |||||

Packaging & Delivery of Wire Rod Q235:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

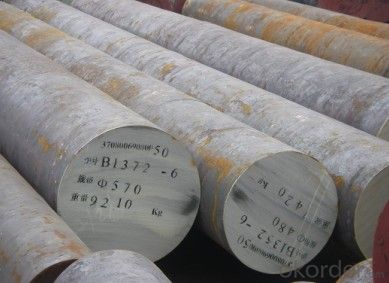

Images:

- Q: What is the tolerance level for steel round bars?

- The tolerance level for steel round bars can vary depending on the specific industry standards and requirements, but commonly, it falls within a range of +/- a few millimeters or less.

- Q: What are the advantages of using tungsten-alloy steel round bars?

- Tungsten-alloy steel round bars offer several advantages over other materials, making them a popular choice in various industries. Firstly, tungsten-alloy steel round bars have exceptional strength and durability. The addition of tungsten to the steel composition significantly improves its hardness and toughness, making it highly resistant to wear, deformation, and fatigue. This enhanced strength ensures that tungsten-alloy steel round bars can withstand heavy loads and high-pressure applications, making them ideal for use in industries such as aerospace, automotive, and construction. Another advantage of using tungsten-alloy steel round bars is their excellent heat resistance. Tungsten has one of the highest melting points among all elements, making it highly suitable for applications that involve extreme temperatures, such as furnace parts, cutting tools, and high-speed machinery. The heat resistance of tungsten-alloy steel round bars allows them to maintain their structural integrity and performance even in demanding environments, minimizing the risk of deformation or failure. Furthermore, tungsten-alloy steel round bars have superior corrosion resistance. The addition of tungsten to the steel alloy forms a protective oxide layer on the surface, which acts as a barrier against corrosive elements, moisture, and chemicals. This corrosion resistance makes tungsten-alloy steel round bars ideal for applications in marine environments, chemical processing plants, and oil and gas industries, where exposure to corrosive substances is common. Additionally, tungsten-alloy steel round bars provide excellent machinability. The hardness and toughness of these bars make them easy to shape, cut, and drill, allowing for precise machining and tight tolerances. This machinability makes tungsten-alloy steel round bars suitable for manufacturing intricate components and parts that require high precision and accuracy. Lastly, tungsten-alloy steel round bars have a high density, which gives them unique properties such as improved radiation shielding capabilities. This makes them valuable in industries where radiation protection is crucial, such as nuclear power plants, medical equipment, and aerospace applications. In conclusion, the advantages of using tungsten-alloy steel round bars include exceptional strength and durability, excellent heat resistance, superior corrosion resistance, excellent machinability, and high density for radiation shielding. These advantages make tungsten-alloy steel round bars a reliable and versatile choice for various industries, ensuring optimal performance and longevity in challenging environments.

- Q: What is the difference between a polished and a precision ground steel round bar?

- A polished steel round bar is a bar that has been polished to achieve a smooth and shiny surface. This involves using abrasive materials to eliminate any flaws or roughness. As a result, the bar is visually appealing and has a high level of aesthetic appeal. On the other hand, a precision ground steel round bar is a bar that has been ground precisely to achieve accurate dimensions and a smooth surface. This grinding process involves removing material from the bar's surface using grinding wheels or other cutting tools. The aim of precision grinding is to ensure that the bar meets specific size and shape requirements, making it suitable for applications that require precise dimensions and tight tolerances. In conclusion, the main difference between a polished and a precision ground steel round bar lies in the purpose of the respective finishing processes. Polishing is primarily done for aesthetic reasons, enhancing the bar's appearance, while precision grinding focuses on achieving precise dimensions and tight tolerances to meet specific technical requirements.

- Q: Can steel round bars be used for construction purposes?

- Indeed, construction purposes can make use of steel round bars. Several applications in construction commonly utilize steel round bars, including reinforcement in concrete structures, support for beams and columns, and as structural components in bridges, buildings, and infrastructure projects. The exceptional tensile strength and durability of steel render it a perfect option for construction purposes, capable of withstanding heavy loads, providing stability, and ensuring the longevity and safety of structures. Furthermore, steel round bars offer versatility, as they can be easily fabricated and customized to meet specific project requirements. Hence, due to their excellent mechanical properties, reliability, and cost-effectiveness, steel round bars find extensive use in the construction industry.

- Q: What is the difference between a seamless and a turned steel round bar?

- The main difference between a seamless and a turned steel round bar lies in their manufacturing process and resulting characteristics. A seamless steel round bar is produced by piercing a solid steel billet, typically through a hot rolling process. This creates a hollow tube-like structure, which is then further elongated and shaped into the desired round bar form. The seamless nature of this bar means that there are no welded joints or seams along its length, resulting in a smooth and continuous surface. This manufacturing method enhances the overall strength and durability of the round bar. On the other hand, a turned steel round bar starts as a solid steel bar, commonly obtained through casting or hot rolling. The bar is then subjected to a machining process known as turning, where it is rotated against a cutting tool to remove material and achieve the desired dimensions and shape. This turning process creates a round bar with a smooth and polished surface. However, unlike a seamless round bar, a turned bar may have mill marks or slight imperfections due to the machining process. In terms of applications, seamless steel round bars are often preferred in industries that require high strength and reliability, such as construction, automotive, and oil and gas. Their uniform structure and absence of welds make them highly resistant to cracking and failure under heavy loads or extreme conditions. Turned steel round bars, on the other hand, are commonly used in applications where a smooth surface finish is desired, such as in decorative pieces or precision components for machinery. Overall, the main difference between a seamless and a turned steel round bar lies in their manufacturing process and resulting characteristics. While both provide a smooth surface finish, seamless round bars offer enhanced strength and reliability due to their seamless structure, whereas turned round bars are often chosen for their precise dimensions and aesthetic qualities.

- Q: How do steel round bars compare to plastic or composite bars?

- Plastic or composite bars cannot match the advantages of steel round bars. Firstly, steel round bars surpass plastic or composite bars in terms of strength and sturdiness. They excel in enduring heavy loads and providing outstanding structural support. Therefore, they are ideal for construction or engineering projects demanding robustness and durability. Secondly, steel round bars exhibit remarkable resistance to impact and wear. They can withstand severe environmental conditions and are less prone to cracking, chipping, or breaking compared to plastic or composite bars. Consequently, steel round bars suit heavy-duty applications where abrasion resistance is crucial. Moreover, steel round bars boast superior heat resistance in comparison to plastic or composite bars. They can endure high temperatures without distorting or compromising their structural integrity. Hence, steel round bars are suitable for applications involving extreme heat, such as machinery or equipment manufacturing. Furthermore, steel round bars are highly versatile and can be easily machined or modified to meet specific requirements. They allow for effortless customization and adaptability through cutting, drilling, bending, or welding. Conversely, plastic or composite bars may have limitations regarding customization or modification. Nonetheless, it is important to consider that steel round bars also have drawbacks when compared to plastic or composite bars. Steel is heavier, which can pose challenges in handling and transportation. Additionally, depending on the specific grade and quality, steel round bars can be more expensive than their plastic or composite counterparts. In conclusion, steel round bars surpass plastic or composite bars in terms of strength, durability, impact resistance, and heat resistance. Although they may have some drawbacks such as weight and cost, their overall performance and versatility make them the preferred choice for numerous high-performance applications.

- Q: Are steel round bars suitable for conveyor belt applications?

- Steel round bars can be suitable for conveyor belt applications, depending on various factors. Steel round bars are known for their strength, durability, and resistance to wear and tear. These qualities make them a viable option for conveyor belt applications that involve heavy loads, high speeds, or abrasive materials. One of the main advantages of using steel round bars in conveyor belt applications is their ability to withstand heavy loads. The strength of steel ensures that the bars can support the weight of the conveyed materials without bending or breaking. This is particularly important in industries where large quantities of bulky or heavy materials need to be transported continuously. In addition, steel round bars are highly resistant to wear and tear. The smooth surface of the bars minimizes friction, reducing the wear on the conveyor belt and extending its lifespan. This is crucial in applications where the conveyor belt is subjected to constant movement and contact with abrasive materials, such as mining or construction industries. Furthermore, steel round bars can withstand high speeds without compromising their structural integrity. They have a high tensile strength, allowing them to handle the forces exerted on the conveyor belt during acceleration or deceleration. This ensures smooth and efficient operation of the conveyor system, minimizing downtime and improving productivity. However, it is important to consider the specific requirements of the conveyor belt application when choosing steel round bars. Factors such as the type of conveyed materials, the environment in which the conveyor operates, and the specific load and speed requirements should be taken into account. In some cases, alternative materials or coatings may be necessary to enhance the performance and longevity of the conveyor system. In conclusion, steel round bars can be suitable for conveyor belt applications due to their strength, durability, and resistance to wear and tear. However, careful consideration of the specific application requirements is necessary to ensure optimal performance and longevity of the conveyor system.

- Q: What are the advantages of using nickel-chromium alloy steel round bars?

- There are several advantages of using nickel-chromium alloy steel round bars in various applications. Firstly, nickel-chromium alloy steel round bars have excellent corrosion resistance properties. The presence of nickel and chromium elements in the alloy enhances its ability to resist corrosion from various environmental factors such as moisture, chemicals, and oxidation. This makes these round bars suitable for use in challenging environments such as marine applications, chemical processing plants, and oil refineries. Secondly, nickel-chromium alloy steel round bars offer high temperature resistance. The combination of nickel and chromium elements in the alloy allows it to withstand elevated temperatures without losing its structural integrity. This makes them suitable for use in heat exchangers, furnaces, and other high-temperature applications. Additionally, nickel-chromium alloy steel round bars have superior mechanical properties. They exhibit excellent strength, toughness, and wear resistance, making them ideal for applications that require high load-bearing capabilities. These round bars also exhibit good ductility, allowing for ease of machining and fabrication. Moreover, nickel-chromium alloy steel round bars have good electrical conductivity. This makes them suitable for electrical and electronic applications where conductivity is essential, such as in the manufacturing of resistors, heating elements, and electrical connectors. Lastly, nickel-chromium alloy steel round bars are readily available and cost-effective. As a widely used material in various industries, these round bars are easily accessible and can be obtained at competitive prices. In summary, the advantages of using nickel-chromium alloy steel round bars include excellent corrosion resistance, high-temperature resistance, superior mechanical properties, good electrical conductivity, and cost-effectiveness. These characteristics make them a preferred choice for a wide range of applications in industries such as construction, automotive, aerospace, and electrical engineering.

- Q: How do steel round bars perform under impact or shock loading?

- Steel round bars generally perform well under impact or shock loading due to their high strength and toughness. The inherent properties of steel, such as its ability to absorb and distribute energy, make it highly resistant to deformation or failure when subjected to sudden forces or impacts. Additionally, the uniformity and reliability of steel's microstructure contribute to its consistent performance and durability in such loading conditions.

- Q: What is the maximum temperature a steel round bar can withstand?

- The maximum temperature that a steel round bar can endure relies on various factors, including the particular type of steel, its composition, and the intended purpose. In general, most commonly used steel grades have an upper temperature limit of approximately 1,200 to 1,400 degrees Fahrenheit (650 to 760 degrees Celsius). However, certain stainless steels possess the ability to withstand higher temperatures, reaching up to 2,200 degrees Fahrenheit (1,200 degrees Celsius). Moreover, specialized heat-resistant alloys like Inconel or Hastelloy can withstand even greater temperatures, up to 2,500 degrees Fahrenheit (1,370 degrees Celsius) or beyond. To ensure the safe and efficient utilization of a specific steel round bar, it is essential to consult the manufacturer's specifications or conduct comprehensive research in order to ascertain its precise maximum temperature limit.

Send your message to us

Hot Rolled D-bar with Many Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords