Hot Rolled Steel Equal Angle Bar Different Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

.

Product Advantages:

OKorder's Angle Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

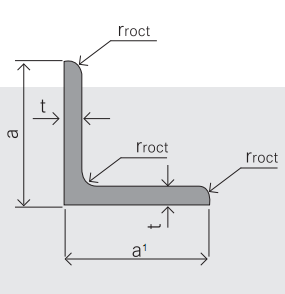

3. Sizes

4. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Packaging & Delivery of Equal Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How do you design connections for steel angles to concrete?

- To design connections for steel angles to concrete, several factors need to be considered. Firstly, the load requirements and type of connection (such as shear, tension, or moment) must be determined. Then, appropriate connection methods like embedded plates, anchor bolts, or post-installed anchors can be selected. The design must also consider the concrete strength, angle size, spacing, and edge distances. Detailed calculations are performed to ensure the connection is safe and meets the applicable design codes and standards. Additionally, factors like corrosion protection and construction feasibility should be considered during the design process.

- Q: Can steel angles be used in marine environments?

- Indeed, the utilization of steel angles is viable in marine environments. Given their robustness and adaptability, steel angles are widely employed in the construction sector. However, the presence of corrosive elements and exposure to saltwater necessitates the use of materials that are resistant to corrosion. Therefore, in marine applications, it is imperative to opt for stainless steel angles or galvanized steel angles as they possess exceptional resistance against corrosion. These materials are equipped with protective coatings or alloys that effectively prevent rusting and deterioration, thereby ensuring their endurance and longevity in marine environments. Furthermore, steel angles can be custom designed and fabricated to adhere to specific requirements and regulations governing marine structures, including shipbuilding, offshore platforms, and marine piers.

- Q: How are steel angles measured and labeled?

- The dimensions and specifications of steel angles govern their measurement and labeling. When measuring steel angles, two primary parameters are considered: the length of the legs and the thickness of the material. The length of the legs is typically measured in inches or millimeters, indicating the distance from the point where the legs meet to the outer edge of each leg. Similarly, the thickness denotes the cross-sectional measurement of the steel angle and is usually given in inches or millimeters. Steel angles are labeled according to a specific notation system, typically comprising three numbers separated by hyphens or slashes. The initial number represents the length of one leg, the second number represents the length of the other leg, and the third number signifies the thickness of the material. For instance, an angle labeled as "2x2x1/4" implies that both legs have a length of 2 inches and the material thickness is 1/4 inch. Occasionally, steel angles may bear additional information, such as the type of steel employed, the manufacturing standard adhered to, or any distinctive features or characteristics. This supplementary information aids in discerning the specific properties and intended usage of the steel angle. In conclusion, steel angles are measured and labeled based on their dimensions and specifications, employing a standardized notation system that effectively communicates information about their size and thickness.

- Q: What are the maximum allowable deflections for steel angles?

- The maximum allowable deflections for steel angles depend on various factors such as the type of angle used, the material properties, the loading conditions, and the design codes and standards being followed. In general, the deflection limits are determined to ensure the structural integrity and functionality of the steel angles. Excessive deflections can cause structural instability, reduced load-carrying capacity, and potential failure of the angles. Design codes and standards such as the American Institute of Steel Construction (AISC) specify deflection criteria for different applications. For example, the AISC 360-16 specification provides deflection limits based on the span length and the serviceability requirements of the specific structure. The allowable deflections for steel angles are usually expressed as a fraction of the unsupported span length. Typical deflection limits for steel angles range from 1/240 to 1/360 of the span length, depending on the specific application and loading conditions. It is important to note that these deflection limits are guidelines and should be assessed in conjunction with other design considerations such as strength, stability, and dynamic effects. Additionally, consulting the applicable design codes and standards, as well as seeking professional engineering advice, is crucial to determine the precise maximum allowable deflections for steel angles in a given project.

- Q: How do you prevent and address corrosion in steel angles?

- There are various effective methods for preventing corrosion and addressing it in steel angles. Here are some steps that can be taken: 1. Ensure proper surface preparation: Before applying any protective measures, it is important to thoroughly clean the steel angles. Use an appropriate solvent or detergent to remove dirt, grease, and other contaminants. 2. Apply protective coatings: To prevent corrosion, it is crucial to apply high-quality coatings. Options include paints, primers, and specialized corrosion-resistant coatings specifically designed for steel. Make sure the coating is suitable for the environmental conditions the steel angles will be exposed to. 3. Consider galvanization: Galvanizing the steel angles can provide excellent corrosion resistance. This involves applying a layer of zinc to create a barrier between the steel and the corrosive elements in the environment. 4. Perform regular inspections and maintenance: Periodically inspect the steel angles for signs of corrosion, such as rust or pitting. Address any corrosion issues immediately to prevent further damage. This may involve removing the damaged coating, treating the corroded area, and reapplying a protective coating. 5. Explore cathodic protection: In critical applications or aggressive environments, it is advisable to consider implementing cathodic protection. This technique involves connecting sacrificial anodes or installing impressed current systems that create an electrochemical reaction to protect the steel angles from corrosion. 6. Control the environment: Minimizing exposure to moisture, humidity, and corrosive chemicals can significantly reduce the risk of corrosion. Proper ventilation, dehumidification, and avoiding direct contact with corrosive substances are important preventive measures. 7. Perform routine cleaning: Regularly clean the steel angles to remove accumulated dirt, debris, or corrosive substances that can accelerate corrosion. It is recommended to use gentle cleaning methods and avoid abrasive materials that could damage the protective coating. Keep in mind that preventing and addressing corrosion in steel angles requires a proactive approach. By implementing these measures, the lifespan of the steel angles can be extended, and their structural integrity can be maintained.

- Q: Can steel angles be used for outdoor applications?

- Yes, steel angles can be used for outdoor applications. Steel angles are made from a strong and durable material, making them suitable for various outdoor projects. They are commonly used in construction, infrastructure, and engineering projects that require structural support or reinforcement. Steel angles can withstand harsh weather conditions, such as rain, snow, and direct sunlight, without deteriorating or losing their strength. Additionally, steel angles can be coated or treated to increase their resistance to corrosion, further enhancing their suitability for outdoor applications. Overall, steel angles are a reliable and versatile choice for outdoor projects that require strength, durability, and long-term performance.

- Q: Can steel angles be used for sign posts?

- Yes, steel angles can be used for sign posts. Steel angles are commonly used in construction due to their strength and durability. They can provide the necessary support and stability for sign posts, especially in areas with high winds or heavy traffic. Additionally, steel angles can be easily welded or bolted together, making them a versatile option for sign post installation. Their resistance to corrosion also ensures a longer lifespan, reducing maintenance and replacement costs.

- Q: What is the typical hardness of steel angles?

- The typical hardness of steel angles can vary depending on the specific grade and manufacturing process, but it is generally within the range of 150 to 200 Brinell Hardness Number (BHN).

- Q: What are the different methods for protecting steel angles from corrosion?

- There are several methods for protecting steel angles from corrosion, including the use of protective coatings such as paint or galvanization, applying corrosion inhibitors, using sacrificial anodes, implementing cathodic protection systems, and regular maintenance and inspection of the angles to identify and address any potential corrosion issues.

- Q: What are the safety precautions when working with steel angles?

- When working with steel angles, it is important to follow certain safety precautions to minimize the risk of accidents and injuries. Here are some key safety measures to consider: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, steel-toed boots, and a hard hat. PPE will protect you from potential hazards like flying debris, sharp edges, and falling objects. 2. Proper Handling: Use mechanical aids, such as cranes or forklifts, to lift and move heavy steel angles. Avoid manual lifting if the weight exceeds your capacity. Ensure the angles are stacked securely and avoid overloading shelves or racks. 3. Work Area Organization: Keep the work area clean and organized to prevent trips, falls, and accidents. Remove any obstructions or clutter that may hinder movement or cause accidents. Clearly mark areas where steel angles are stored or being worked on to prevent unauthorized access. 4. Inspect Tools and Equipment: Regularly inspect and maintain tools and equipment used to work with steel angles. Ensure they are in good working condition, and if any defects are noticed, repair or replace them promptly. Avoid using damaged or faulty equipment. 5. Cutting and Grinding: When cutting or grinding steel angles, always wear appropriate eye and face protection to shield against sparks, dust, and debris. Utilize tools specifically designed for cutting and grinding steel. Ensure proper ventilation in enclosed spaces to minimize the risk of inhaling toxic fumes. 6. Proper Storage: Store steel angles in a designated area where they are not at risk of falling or causing accidents. Use racks or shelves that are suitable for supporting the weight and size of the angles. Securely stack and strap them to prevent them from toppling over. 7. Fire Safety: Steel angles can generate sparks when being cut or welded. Ensure that there are proper fire prevention measures in place, such as fire extinguishers and fire-resistant materials nearby. Keep flammable substances away from the work area. 8. Training and Awareness: Provide appropriate training to all workers involved in handling steel angles. Ensure they have a thorough understanding of the safety precautions, procedures, and emergency protocols. Encourage open communication and the reporting of any safety concerns or incidents. By adhering to these safety precautions, you can minimize the risk of accidents and create a safer working environment when handling steel angles. Always prioritize your safety and the safety of others while working with steel angles.

Send your message to us

Hot Rolled Steel Equal Angle Bar Different Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches