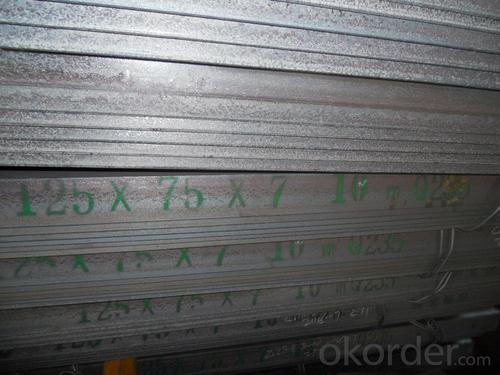

Hot Rolled Steel Equal Angle with Many Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Equal Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Equal Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can steel angles be used as framing members for suspended ceilings?

- Yes, steel angles can be used as framing members for suspended ceilings. Steel angles are commonly used in construction for their strength and durability. When used as framing members for suspended ceilings, they provide support and stability to the ceiling system. Steel angles can be easily attached to the walls or other structural components, and they can be cut to the desired length to fit the specific ceiling dimensions. Additionally, steel angles can be painted or coated to match the aesthetic requirements of the suspended ceiling. Overall, steel angles are a reliable and suitable choice for framing members in suspended ceilings.

- Q: Can steel angles be used in cold-formed steel construction?

- Yes, steel angles can be used in cold-formed steel construction. Cold-formed steel construction involves the use of thin gauge steel sheets that are formed into various shapes and profiles, including angles. Steel angles are commonly used in cold-formed steel construction for a variety of applications, such as framing systems, support members, and bracing elements. They provide structural strength, stability, and can be easily connected or welded to other cold-formed steel components. Additionally, steel angles can be customized and fabricated to meet specific project requirements and design specifications in cold-formed steel construction.

- Q: How are steel angles measured and labeled?

- Steel angles are measured and labeled based on their dimensions and specifications. The measurement of steel angles involves two main parameters: the length of the two sides (legs) and the thickness of the material. The length of the legs is typically measured in inches or millimeters and denotes the distance from the point where the two legs meet to the outer edge of each leg. The thickness is the measurement of the steel angle's cross-section and is usually given in inches or millimeters as well. Steel angles are labeled using a specific notation system. The notation typically includes three numbers separated by hyphens or slashes. The first number represents the length of one leg, the second number represents the length of the other leg, and the third number represents the thickness of the material. For example, an angle labeled as "2x2x1/4" means that both legs have a length of 2 inches and the thickness of the material is 1/4 inch. In some cases, steel angles may also be labeled with additional information such as the type of steel used, the manufacturing standard, or any special features or characteristics. This additional information helps in determining the specific properties and intended use of the steel angle. Overall, steel angles are measured and labeled based on their dimensions and specifications, following a standardized notation system that provides clear information about their size and thickness.

- Q: Can steel angles be used in sports facilities or stadium constructions?

- Yes, steel angles can be used in sports facilities or stadium constructions. Steel angles are commonly used in construction projects due to their strength and durability. They can be used to provide support and stability in various structural elements, such as beams, columns, and frames, making them suitable for use in sports facilities or stadium constructions where robustness and reliability are crucial.

- Q: How are steel angles installed or fixed in place?

- Steel angles are widely utilized in construction to supply structural support and reinforcement, with their installation or fixation employing various techniques based on the particular application and project requirements. One prevalent approach to installing steel angles is through welding, whereby the angles are permanently fused to the desired location using a welding machine. This method guarantees a robust and long-lasting connection that keeps the angles securely in place, even when subjected to substantial loads or vibrations. However, welding necessitates skilled labor and specialized equipment. Another technique involves bolting, whereby steel angles are affixed to the supporting structure using bolts or screws. This method allows for effortless installation and removal, making it suitable for situations requiring adjustments or modifications. Bolting also offers flexibility in terms of repositioning or replacing the angles if necessary. In certain instances, steel angles are attached to the structure using adhesive bonding, which entails applying a sturdy adhesive material between the angle and the supporting surface. Adhesive bonding proves particularly advantageous when welding or bolting is impractical or undesired. However, it is crucial to ensure that the adhesive employed is suitable for the specific application and capable of withstanding the loads and environmental conditions. Furthermore, a combination of methods can be employed to install steel angles. For instance, welding can serve as the primary attachment, while bolts or adhesive bonding can be employed as secondary supports or reinforcements. Consulting structural engineers or professionals is essential in determining the most appropriate method for installing steel angles, taking into account the project's unique requirements, load conditions, and local building codes. Proper installation guarantees that the angles are securely fixed in place, delivering the necessary strength and stability to the structure.

- Q: Are steel angles susceptible to fatigue failure?

- Yes, steel angles can be susceptible to fatigue failure. Fatigue failure occurs when a material undergoes repeated loading and unloading cycles, leading to the initiation and propagation of cracks within the material. Steel angles, like any other structural components, can be subject to cyclic loading conditions, such as vibrations, oscillations, or repeated stress applications. Fatigue failure in steel angles is influenced by various factors, including the material's properties, the geometric shape of the angle, the magnitude and frequency of the applied loads, and the presence of any defects or stress concentrations. The presence of notches, welds, or sharp corners can act as stress raisers, leading to localized stress concentrations and potential crack initiation sites. To mitigate the risk of fatigue failure, engineers and designers consider several strategies. Firstly, understanding the anticipated loading conditions and designing the structure with appropriate safety factors can help ensure that the steel angles are not subjected to stress levels that exceed their fatigue strength. Secondly, minimizing stress concentrations through proper design, such as using rounded corners or fillets, can help distribute the stress more uniformly and reduce the likelihood of crack initiation. Additionally, regular inspection and maintenance of structures can help identify any potential fatigue cracks and allow for necessary repairs or replacements.

- Q: Can steel angles be used in bridge construction?

- Yes, steel angles can definitely be used in bridge construction. Steel angles, also known as L-shaped structural steel, are commonly used as cross-sectional supports in bridge construction. They are particularly useful for providing stability, strength, and rigidity to bridge structures. Steel angles are versatile and can be used for various bridge components such as beams, trusses, and bracing systems. They are often welded or bolted together to form structural connections, ensuring the integrity and load-carrying capacity of the bridge. Steel angles offer several advantages in bridge construction, including their high strength-to-weight ratio, durability, and resistance to corrosion. Overall, steel angles are a reliable and widely used component in the construction of bridges.

- Q: Can steel angles be used in agricultural applications?

- Yes, steel angles can be used in agricultural applications. They are commonly used in the construction of buildings, fences, and equipment in the agricultural industry due to their strength, durability, and versatility.

- Q: Can steel angles be used in architectural sculptures and installations?

- Yes, steel angles can definitely be used in architectural sculptures and installations. Steel angles provide structural support and stability, making them ideal for creating intricate and visually appealing designs. They can be bent, welded, or cut to fit specific requirements, offering versatility in creating unique architectural forms. Additionally, steel angles are durable and weather-resistant, making them suitable for outdoor installations.

- Q: Can steel angles be used as a support for shelving?

- Indeed, steel angles have the capacity to serve as a reliable support for shelving. With their robustness and durability, steel angles offer exceptional support for shelves. They are frequently employed in industrial environments and demanding scenarios that necessitate a sturdy and steady shelving system. Steel angles can effortlessly be affixed to walls or other structures to establish a framework for shelves or can be utilized as brackets to directly uphold the shelves. Given their solid construction and ability to bear heavy loads, steel angles prove themselves as a dependable choice for supporting shelving units.

Send your message to us

Hot Rolled Steel Equal Angle with Many Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords