Steel Equal Angle Bar for Tower Construction with Small Tolerance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Equal Angle Bar Description:

Steel equal angle bar is a main kind of structure steel and the section is like a letter L. We use steel equal angle bar for tower construction. Steel equal angle bar can be erected as soon as the materials are delivered on site. High strength, stiffness, toughness, and ductile properties are advantages of this kind of steel equal angle bar.

2. Main Features of Steel Equal Angle Bar:

• Strength - Having high strength, stiffness, toughness, and ductile properties, structural steel is one of the most commonly used materials in commercial and industrial building construction.

• Constructability - Steel equal angle Bar can be developed into nearly any shape, which are either bolted or welded together in construction. Structural steel can be erected as soon as the materials are delivered on site, whereas concrete must be cured at least 1–2 weeks after pouring before construction can continue, making steel a schedule-friendly construction material.

• Fire resistance - Steel is inherently a noncombustible material. However, when heated to temperatures seen in a fire scenario, the strength and stiffness of the material is significantly reduced. The steel equal angle bar can be enveloped in sufficient fire-resistant materials, increasing overall cost of steel structure buildings.

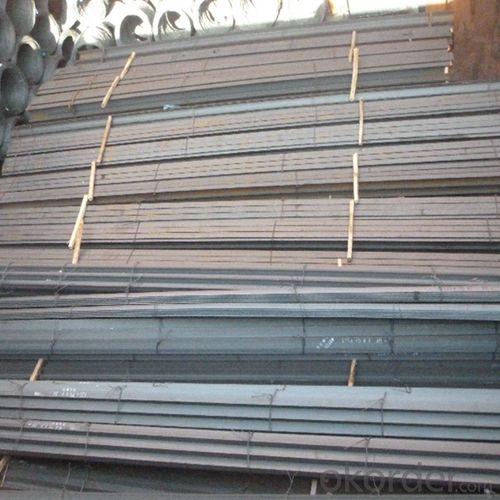

3. Steel Equal Angle Bar Images:

4. Steel Equal Angle Bar Specification:

Angle | KG/M | Angle | KG/M | Angle | KG/M | Angle | KG/M |

20X20X3 | 0.889 | 60X60X5 | 4.570 | 90X90X8 | 10.946 | 130X130X12 | 23.600 |

20X20X4 | 1.145 | 60X60X6 | 5.427 | 90X90X9 | 12.220 | 130X130X13 | 25.400 |

25X25X2 | 0.763 | 63X63X4 | 3.907 | 90X90X10 | 13.476 | 130X130X14 | 27.200 |

25X25X3 | 1.124 | 63X63X5 | 4.822 | 90X90X15 | 15.940 | 130X130X16 | 30.900 |

25X25X4 | 1.459 | 63X63X6 | 5.721 | 100X100X6 | 9.366 | 140X140X10 | 21.488 |

30X30X2 | 0.922 | 63X63X8 | 7.469 | 100X100X7 | 10.830 | 140X140X12 | 25.522 |

30X30X3 | 1.373 | 63X63X10 | 9.151 | 100X100X8 | 12.276 | 140X140X14 | 29.490 |

30X30X4 | 1.786 | 70X70X4 | 4.372 | 100X100X10 | 15.120 | 140X140X15 | 31.451 |

36X36X3 | 1.656 | 70X70X5 | 5.397 | 100X100X12 | 17.898 | 140X140X16 | 33.393 |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about the corrosion of the products?

When the steel equal angle bar in contact with water, can corrode, creating a potentially dangerous structure. Measures must be taken in structural steel construction to prevent any lifetime corrosion. The steel can be painted, providing water resistance. Also, the fire resistance material used to envelope steel is commonly water resistant.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.③What is the difference between steel angle bar and traditional material?

Steel equal angle bar differs from concrete in its attributed compressive strength as well as tensile strength.

- Q: Can steel angles be used for framing or supporting exterior cladding systems?

- Yes, steel angles can be used for framing or supporting exterior cladding systems. Steel angles are commonly used in construction as they provide structural support and stability. When used for framing or supporting exterior cladding systems, steel angles offer durability and strength, ensuring the stability and longevity of the cladding. They are often used to create a framework or support structure for attaching the cladding materials, such as siding or panels, to the building's exterior. Steel angles can be easily customized and fabricated to fit specific design requirements, making them a versatile choice for framing or supporting exterior cladding systems.

- Q: Can steel angles be used for staircase handrails?

- Certainly, staircase handrails can indeed be constructed using steel angles. These steel angles possess great versatility and strength, which renders them a suitable choice for providing support and stability to staircase handrails. By welding or bolting them easily to the staircase structure, a secure connection is ensured. Moreover, steel angles are available in a wide array of sizes and lengths, allowing for customization to perfectly fit the specific dimensions and design requirements of the staircase. Furthermore, these steel angles can be finished with various coatings, such as powder coating or galvanization, to enhance their durability and resistance against corrosion. All in all, steel angles present a practical and dependable option for the construction of staircase handrails.

- Q: What are the different types of steel angles used in structural engineering?

- Steel angles are commonly utilized in structural engineering for their versatility and strength. They are available in various shapes and sizes, typically made from carbon steel or stainless steel, to suit specific structural applications. The following are some of the types of steel angles frequently used in this field: 1. L-Shaped Angles: These angles, also known as equal leg angles, have equal dimensions for both legs, resulting in a 90-degree angle. They are commonly employed as structural components in building frames, supports, and bracing systems. 2. Unequal Leg Angles: Unlike equal leg angles, these angles have differing lengths for each leg, resulting in an unequal angle. They are often used when a larger load-bearing capacity or specific structural requirements are necessary. 3. Angle Iron: Angle iron is a broad term encompassing various steel angles that have been rolled into a 90-degree angle. It is frequently used as a structural element in construction projects, such as framing, bracing, and supports. 4. Slotted Angles: Slotted angles are a variation of angle iron that feature holes or slots along the length of the angle. These holes allow for flexibility in attaching other structural components or accessories, making them versatile for shelving, racks, and workbenches. 5. Stainless Steel Angles: Stainless steel angles are fabricated from corrosion-resistant stainless steel alloys. They are commonly employed in applications where strength, durability, and resistance to corrosion are crucial, such as in the marine, food processing, and chemical industries. 6. Rolled Steel Angles: Rolled steel angles are produced by rolling steel plates or sheets to form an angled shape. They are widely used in construction projects due to their high strength-to-weight ratio and cost-effectiveness. 7. Structural Steel Angles: Structural steel angles are specifically designed for structural applications, such as supporting beams, columns, and trusses. They are typically manufactured from high-strength carbon steel and are available in various sizes and thicknesses to meet specific load-bearing requirements. In conclusion, the diverse range of steel angles used in structural engineering offers engineers numerous options to design and construct robust and efficient structures. The selection of the appropriate angle depends on factors such as load requirements, structural design, and environmental conditions.

- Q: Can steel angles be fire-resistant?

- Indeed, steel angles possess fire-resistant qualities. Being a material, steel inherently possesses fire resistance due to its high melting point and low thermal conductivity. When faced with elevated temperatures, steel angles can retain their structural integrity and withstand deformation for a significant duration. Furthermore, fire resistance in steel angles can be augmented through diverse approaches, such as the utilization of fire-resistant coatings or the integration of fire-resistant materials in their design. These measures serve to heighten the fire resistance capacity of steel angles, rendering them appropriate for scenarios where fire protection is imperative, such as the establishment of fire-resistant walls, ceilings, and structural systems in construction projects.

- Q: Can steel angles be used in the construction of hospitals?

- Yes, steel angles can be used in the construction of hospitals. Steel angles are commonly used in construction projects as they provide structural support and stability. In the construction of hospitals, steel angles can be used in various applications such as framing, support beams, trusses, and reinforcement for walls and floors. Steel angles are known for their strength, durability, and resistance to fire, making them suitable for withstanding the high demands and safety requirements of hospital buildings. Additionally, steel angles can be easily fabricated and manipulated to fit the specific design and structural requirements of a hospital, allowing for flexibility in construction. Overall, steel angles are a reliable and versatile material that can be effectively used in the construction of hospitals.

- Q: How do you determine the center of gravity for a steel angle?

- To determine the center of gravity for a steel angle, you need to consider its shape and dimensions. The center of gravity is the point where the weight of the object is evenly distributed, and finding this point is crucial for understanding its stability and balance. First, measure the length, width, and thickness of the steel angle. These measurements will help you calculate the area and volume of the angle, which are essential for determining the center of gravity. Next, locate the centroid of the steel angle. The centroid is the geometric center of the object, and it represents the point where all the weight is concentrated. For a symmetrical steel angle, the centroid will be at the intersection of the two axes of symmetry. However, if the angle is asymmetrical, finding the centroid might require more complex calculations. To calculate the centroid, use the formulas for the area moment of inertia. These formulas depend on the shape of the angle. For example, if the angle is a simple L-shape, the centroid can be determined by finding the average of the coordinates of the two legs' centroids. Once you have determined the centroid, you can then locate the center of gravity. The center of gravity coincides with the centroid of the steel angle in uniform density objects. However, for objects with non-uniform density, additional calculations might be required to account for variations in weight distribution. In summary, determining the center of gravity for a steel angle involves measuring its dimensions, calculating the centroid based on its shape, and then locating the center of gravity. This information is crucial for understanding the angle's stability and balance, especially in applications where it will be subjected to external forces or loads.

- Q: What is the carbon content of steel angles?

- The carbon content of steel angles can vary depending on the specific grade or type of steel, but typically ranges from 0.05% to 0.25%.

- Q: Can steel angles be used in decorative or architectural applications?

- Yes, steel angles can be used in decorative or architectural applications. They provide structural support while also adding a modern and industrial aesthetic to the design. Steel angles can be used to create features like exposed beams, decorative trims, and ornamental structures, making them versatile for various architectural and decorative purposes.

- Q: Can steel angles be used as reinforcement in concrete structures?

- Indeed, reinforcement in concrete structures can be achieved by utilizing steel angles. These angles, typically in the shape of L or angles, are inserted into the concrete to bolster its strength and provide support to the structure. By resisting tensile forces, these angles effectively prevent concrete from cracking or failing. They find extensive use in various applications like beams, columns, and walls, significantly enhancing the structural integrity and load-bearing capacity of these concrete components. Moreover, the ease with which steel angles can be welded or bolted together makes them a flexible and economical choice for reinforcing concrete structures.

- Q: How do steel angles perform under static or stationary loading conditions?

- Steel angles are commonly used in construction and engineering applications due to their strength and versatility. Under static or stationary loading conditions, steel angles exhibit excellent performance and stability. Static loading refers to a situation where a load is applied to the angle and remains constant without any motion. Steel angles are specifically designed to withstand such loading conditions. Due to their structural properties, steel angles have a high resistance to bending and twisting forces. This allows them to effectively support heavy loads without experiencing significant deformation or failure. Steel angles distribute the applied load evenly along their length, which helps to minimize stress concentrations. This property ensures that the angle can efficiently transfer the load to the supporting structure, providing stability and structural integrity. Additionally, steel angles can withstand compressive forces, which try to shorten or compress the material. The shape and cross-section of steel angles, specifically their L-shaped profile, contribute to their ability to resist compressive loading. This feature makes steel angles suitable for applications where static loads exert compressive forces, such as columns, beams, and bracing elements. Moreover, steel angles have a high resistance to shear forces, which occur when two or more parts of a structure slide or move in opposite directions. The design of steel angles, with their perpendicular legs, enhances their shear strength, allowing them to effectively resist shear loading under stationary conditions. In summary, steel angles perform exceptionally well under static or stationary loading conditions. Their structural properties, such as resistance to bending, twisting, compression, and shear forces, make them suitable for a wide range of applications in construction and engineering.

Send your message to us

Steel Equal Angle Bar for Tower Construction with Small Tolerance

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords