Stayed-cable Cantilever Traveller

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

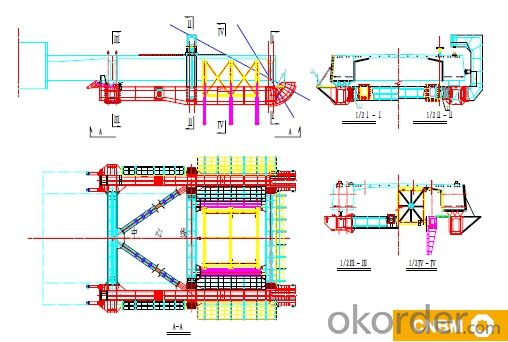

STAYED-CABLE CANTILEVER TRAVELLER

Stayed-cable cantilever traveller is applicable to large-scale stay-cable

cantilever casting bridge with wide bridge deck, heavy and long segment. Most of

the componants concentrates on bottom frame and walking system. It has no main

frame, at the same time, the lift is done by the stay-cable of the bridge. Comparing

with other types, the sigle weight of stayed-cable cantilever traveller is heavier.

●Low gravity of front trancerse beam

●Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

●Safe & easy operation, easy fixing, and safty during walking

●Big operational space under the main frame, and easy installation and removal

- Q: Hanging basket concrete pouring construction control points

- 3 pouring operations caused by the deformation of the prestressed channel deformation, deflection, etc.;4 concrete upper and lower intervals for too long, resulting in construction joints;

- Q: Hanging basket construction can bind steel

- At the intersection of steel, the application of 0.7~2.0 mm wire, according to figure 8 staggered or cruciform manner by butting, butting

- Q: The difference between cast-in-place and hanging basket construction? Why should the construction of hanging basket 0123... Block? The cast-in-place bracket is also divided into pouring and hanging basket so what is the difference between (except for economic differences)

- The difference is that the stent can be poured into the entire collapse of the pouring basket must be divided into sections

- Q: Hanging basket construction which test items

- Wire rope, safety rope, safety lock, some local arms also need to do.

- Q: What is the function of the rain - water hanging basket device in the rainwater collection system

- The rain, rain interception hanging basket device on both sides of a basket, can regularly to take out the equipment to remove rubbish.

- Q: The effect of hanging basket

- To achieve the rapid construction of the bridge box beam casting speed 1 investment in the province of 1 excellent quality, safety and good results of 1

- Q: Operating rules for hanging baskets

- The hanging basket construction technology of formwork installation requirements is very high, must be strong, to prevent overturning, concrete pouring down. In addition, the control of formwork elevation is directly related to the precision of pouring concrete and the height of the box girder. Therefore, the elevation of formwork must be determined according to the pre camber of the design and the deflection of the basket.Technical specification for operation of formwork must pay attention to the following points: A1 first before using the rod on the beam bottom die height; B1 theodolite fixed bottom die axis; C1 fixed bottom die, covered with plastic plates, and adjust the width of the middle floor steel frame production to adjust the width of the bottom mold; the elevation of D, adjusting the lateral mode and the edge template and inclination; the elevation of E1 using the template template before adjusting rod.

- Q: Vertical embedding of hanging basket

- The reserved hole of the hanging basket must also ensure the correct position and the verticality of the reserved hole. The reserved hole pipe should be welded and fixed with steel pipe, which can prevent the concrete from entering the pipe o

- Q: Are there any hanging baskets on both sides of the hanging beam 0

- In the 1# pre pressure when the basket has been removed from the non elastic deformation, so no need to hang basket that is 2# block pre pressure.

- Q: What are the specific steps of hanging basket construction and hanging basket construction

- First, to navigation, two is the cost of setting up a high bracket. So people think of the bridge in the river is not set up under the premise of the construction of the bridge beam, so hanging basket construction method appeared. Is the use of the construction of the anchor anchor in the shape of the former section of beam and slab concrete above to the beam plate of the next section of beam slab concrete cast-in-place construction. Because the stent is hung in a molding on the concrete, the two bracket also bear after a period of concrete construction of the template function, like a basket, so we hang this called "hanging basket in the concrete pouring molding template has been"

Send your message to us

Stayed-cable Cantilever Traveller

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords