Low Gravity Stayed-cable Cantilever Traveller

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

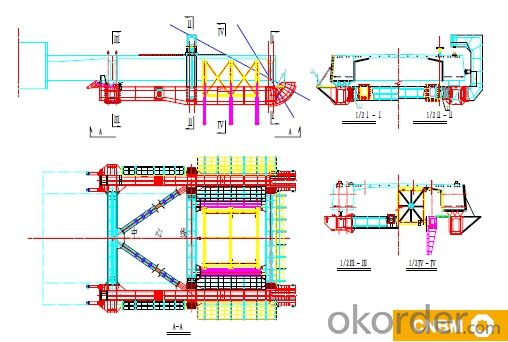

STAYED-CABLE CANTILEVER TRAVELLER

Stayed-cable cantilever traveller is applicable to large-scale stay-cable

cantilever casting bridge with wide bridge deck, heavy and long segment. Most of

the componants concentrates on bottom frame and walking system. It has no main

frame, at the same time, the lift is done by the stay-cable of the bridge. Comparing

with other types, the sigle weight of stayed-cable cantilever traveller is heavier.

●Low gravity of front trancerse beam

●Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

●Safe & easy operation, easy fixing, and safty during walking

●Big operational space under the main frame, and easy installation and removal

- Q: What is the meaning of hanging basket in construction

- A counterweight on the roof, the floor can be free to lift, for workers to work inside the platform!

- Q: Construction scheme of hanging basket

- Each pier is equipped with 23 cantilever sections: 5*2.5m + 5*3.0m + 5*3.5m + 8*4.0m. Beam length of 4.0m, maximum weight 156 tons. The cross section of the box girder: the width of the top plate is 15.42m, the width of the web is 7.5m, and the height of the beam is changed from 0 8.8m to the 3.0m of the block 23 according to the two parabola.

- Q: Summary of hanging basket construction:

- Pay attention to the durability of the cable, the necessary measures in the protection.

- Q: Hanging basket construction 0# block which is, can provide a schematic?

- You said the first row should be aware of the 0# pier, 1# pier, pier number, generally starting from the first pier or abutment number. And said that the 0# block is the first section of a pier pouring. It is generally expressed as 1# pier 0# block, n# block n# block.You're not the structure of each row are single pier I understand refers to the single bridge, down line some bridge is separated, so that the bridge is actually two pieces of the bridge, such a position to the two hanging basket, so also on pier two downstream. If you encounter an elevated ramp, it may not be 2, there will be more.

- Q: On the problem of the hanging basket preloading procedure? Construction of the two main piers, the progress of the first, the previous one to hang the basket pre pressure, then the second need to pre pressure?

- On the problem of the hanging basket preloading procedure? Construction of the two main piers, the progress is divided into

- Q: Do the Populations Of the Countries of the world really believe that all Americans are Pompous, Arrogant, loud, and demanding, because of the personalities of SOME of those who travel the world. Perhaps some of your opinions are formed because of trips you have made to the States, too. Were you treated rudely while visiting here? Does the Media in your country Help form your opinion of us, or perhaps the Media from our country, that you may have seen. It seems that World opinion of Americans is pretty poor these days, and I am concerned about that. Most of us are pretty good , And some of us are not, just like any other country. I am just wondering about your thoughts.

- Americans USED to be much better hosts then guests. Now we are pretty much crap at each side.

- Q: What are the characteristics of the "hanging basket" bridge? What are the advantages and characteristics of such a bridge?

- I don't know what the "basket" bridge, know that there is X-arch Bridge

- Q: Can you list all the characters form The Time Traveler's Wife? Help!

- Henry DeTamble Clare Abshire Gomez Charisse Annette DeTamble Richard DeTamble Mrs. Kim (Kimy) Dr David Kendrick Alba DeTamble Lucille Abshire Phillip Abshire Mark Abshire Sharon Alicia Abshire Ingrid Celia Attley Ben Etta Nell

- Q: Can you please list them ALL because I really need it for my book report =) thanks

- Some will eventually answer this for you but you should consider doing your OWN homework. This is actually a really nice story so you should read it!

- Q: Combined with the hanging basket pouring construction process, the paper puts forward the quality control points and methods of hanging basket continuous casting box girder

- Hanging basket when walking, hanging basket as far as possible to do the same time, the difference between the asymmetric distance between the hanging basket is 5cm;One must be responsible for observing the synchronization of walking, the two person is responsible for observing the operation of the walking anchor beam, the two is responsible for observing the operation of the outer die frame bearing;

Send your message to us

Low Gravity Stayed-cable Cantilever Traveller

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords