Convenient Efficient Bridge Formwork With Timber Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

bridge deck formwork

mivan aluminium formwork

permanent formwork systems

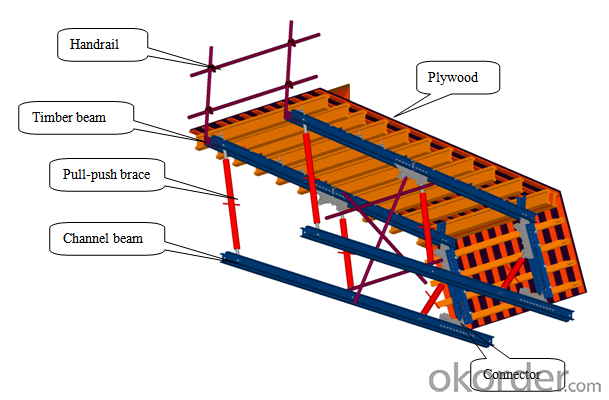

Convenient Efficient Bridge Formwork With Timber Beam, Plywood

Description:

1. Brief introduction

GB system-A is a kind of formwork especially for the bridge deck construction.

2. Competitive advantage

①. Prefabricated connection, convenient and efficient.

②. Light weight but high bearing capacity.

③. Timber is easy resized, so the Tim-formwork is relatively easier to change self’s size and shape. This approved formwork’s economical efficiency.

3. Applications

- Q: Car hanging basket, green, yellow different license, according to what standard hang

- Test license: yellow black, after the word "trial" words; foreign vehicles temporary entry license: white red black and white words "temporary entry";So that a small number of foreign car license on the consulate of the country is the name of the establishment of diplomatic relations, and the number of regulatory authorities in the region has nothing to doAs well as the emergence of the first period of Beijing personality license. White blue at the end of the six character numbers or letters, black fontThere are also a wide variety of game licenses

- Q: The definition of hanging basket construction, historical background

- With the development of material science and computer science, a lot of cable-stayed bridges have been built at home and abroad since the Stromsun bridge in 1956 started the apex of modern cable-stayed bridge. The cable-stayed bridge has been developed rapidly because of its advantages such as large span, good structural performance, simple construction, easy maintenance, low cost and attractive appearance.

- Q: DARK LEVEL 03Sign-Up: 11/04/07Posts: 171I always wanted my real life clan, tribe, band of gypsies, traveling commune, what ever the hell you want to call it.I always wanted to have my own group of way ward wanders that travel place to place together.I just think it would be nice to have that.Thoughts, comments, suggestions? Wanna join?

- I think you should sign up for International Living, many agents will guide you and lead you the way to your wanted life style in travelling for free all over this world. My parents do not allow me to join the groups.

- Q: What are the key processes of hanging basket construction

- 5, construction of prestressed beam shape control; 6, 7; and the closure above and the construction of system transformation are met according to arrangement of students problems in practical work and, for reference, if there is a problem, please timely communication.

- Q: On the problem of the hanging basket preloading procedure? Construction of the two main piers, the progress of the first, the previous one to hang the basket pre pressure, then the second need to pre pressure?

- Install side span closure section, installation of hanging mold closure segment skeleton, formwork, steel banding, installation of prestressed pipe and the core concrete pouring, side span closure segment and maintenance - tension closure segment longitudinal, transverse and vertical prestressed grouting, removing the side line and cross - - side span closure segment construction support the landing gear box girder.

- Q: Why from the beginning of cantilever beam pouring cantilever end?

- General joints are the final processing, in accordance with this principle, you can infer the front end (Yuan Duan) pouring, and finally deal with the old and new material seam problem

- Q: Construction technology of bridge hanging basket

- Beam section constructionA, adjust the elevation of the bottom mold, set the pre camber;B, lashing steel and web reinforcement, installation of floor and web longitudinal prestressed pipe;C, installation of internal mold;D, lashing roof reinforcement, the installation of vertical prestressed pipe;E, pouring concrete;F, health, tension, grouting, sealing anchor.

- Q: What is the meaning of "hanging basket" in building construction

- It is a platform surrounded by railings, suspended on the roof of the wall with a rope

- Q: What should be paid attention to in the construction of cast in place box girder of long span bridge hanging basket

- Attention should be paid to the construction of cast in place box girder of long span bridge hanging basket:1, pay attention to the pouring quality of concrete under anchor.2, the implementation of the whole process of construction survey and monitoring, should be entrusted with a professional qualification of the monitoring team for dynamic monitoring to ensure that the cast-in-place box girder elevation, axis and closure of the error to meet the requirements of the specification.3, beam bottom and Liang Ceyi temperature shrinkage cracks.

- Q: Combined with the hanging basket pouring construction process, the paper puts forward the quality control points and methods of hanging basket continuous casting box girder

- The key points of quality control: 1, hanging basket template (including the bottom mold and the side mold) elevation 2, hanging basket preloading ensuring the load quantity; 3, the hanging basket forward, need special attention, when the cradle walking the preparatory work before the improvement, check again walking and walking condition of anchor beam connection rod the bottom, hanging point should adopt steel wedge pad, and ensure the stability of suspension;

Send your message to us

Convenient Efficient Bridge Formwork With Timber Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords