Safty Triangular Form Traveller in China

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

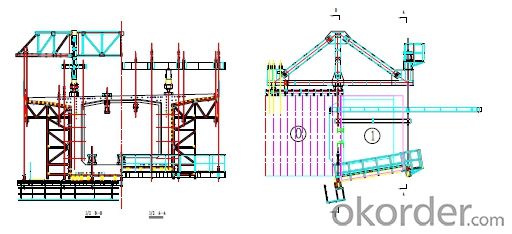

TRIANGULAR FORM TRAVELLER

Trianngular form traveler has the advantages of low gravity of front

trancerse beam, safe & easy operation, easy fixing, and safty during

walking, etc..

During the designing of the form traveller, we always provide

different modes of traction, such as hydraulic pushing mode or

pulling mode, and chain hoist mode, etc. to the constructors for their

choice.

The design of the form traveller could be divided into two types:

external sliding girder and self-moving exteral formwork according to

de construction conditions. When the site condition does not allow

to remove the form traveller at the closure part which have to go

backwards to segment, the second type is suggested.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q: Construction of extra large bridge

- Install side span closure section, installation of hanging mold closure segment skeleton, formwork, steel banding, installation of prestressed pipe and the core concrete pouring, side span closure segment and maintenance - tension closure segment longitudinal, transverse and vertical prestressed grouting, removing the side line and cross - - side span closure segment construction support the landing gear box girder.

- Q: The definition of hanging basket construction, historical background

- Construction craft: 1 hanging basket hanging void, at this point the anti force downward force to the hanging beam hanging basket, hanging basket and the longitudinal beams under negative bending moment. 2 hanging basket forward, hanging basket still bear negative moment, a single arm state. 3 hanging basket beam lifting, after anchorage anchorage, the hanging basket is in place, after the anti point elevation roughly leveling, set preraised height. The 4 cable is connected with the hanging basket, and the first cable tension is carried out, and the front pivot point of the hanging basket is stressed. 5 to the 1/2 beam section for the second cable tension. When the concrete beam of the 6 section is completely cross section, the elasticity of the end of the basket is less than the specified value. 7 detect the beam elevation, the concrete strength to reach the tension of prestressed beam. 8 hanging basket to be moved forward.

- Q: There are several construction methods of bridge hanging

- You mean the hanging basket? The hanging basket is divided into a front fulcrum hanging basket and a rear pivot hanging basket.

- Q: Cantilever pouring construction should pay attention to what

- The main equipment of the cantilever method is a pair of walking hanging basket, pull anchor in Zhang and pier has connected mobile beam on the whole hanging basket, lashing reinforcement, formwork, pouring concrete, prestress are carried out on the. After the completion of the construction of this section, the hanging basket symmetrical move forward a section, the next pair of beam section construction, in advance, until the cantilever beam section pouring completed.

- Q: The difference between cast-in-place and hanging basket construction? Why should the construction of hanging basket 0123... Block? The cast-in-place bracket is also divided into pouring and hanging basket so what is the difference between (except for economic differences)

- The carrying capacity of the hanging basket is limited, and the bracket can be set up according to the requirement.

- Q: After the completion of prestressed tension grouting on the basket can move forward

- Therefore, it is necessary to strictly control the grouting process. Do not allow the prestressed tension after the completion of the grouting on the basket forward. In reality no grouting on the hanging basket forward without accident, mainly due to the design is conservative, safety factor and other factors, to ensure the normal operation of the structure, however, once appear quality accident, it will investigate the problems existing in the construction.

- Q: The effect of hanging basket

- To achieve the rapid construction of the bridge box beam casting speed 1 investment in the province of 1 excellent quality, safety and good results of 1

- Q: Is there any paperwork and forms a traveler from USA to Dubai should look into?

- You do not need any paperwork if you travel to Dubai. USA citizens do not need visa for Dubai. You can just go trough the immigration and they will give you a visitor visa for 30 days.

- Q: Hanging basket construction steel binding labor costs a ton of money

- Two provide semi-finished steel transport B from the steel processing field will be processed to cantilever at

- Q: Why from the beginning of cantilever beam pouring cantilever end?

- General joints are the final processing, in accordance with this principle, you can infer the front end (Yuan Duan) pouring, and finally deal with the old and new material seam problem

Send your message to us

Safty Triangular Form Traveller in China

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords