Triangular Form Traveller in High Quality

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

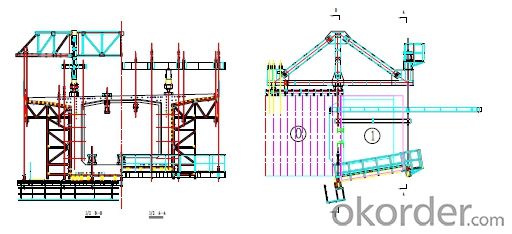

TRIANGULAR FORM TRAVELLER

Trianngular form traveler has the advantages of low gravity of front

trancerse beam, safe & easy operation, easy fixing, and safty during

walking, etc..

During the designing of the form traveller, we always provide

different modes of traction, such as hydraulic pushing mode or

pulling mode, and chain hoist mode, etc. to the constructors for their

choice.

The design of the form traveller could be divided into two types:

external sliding girder and self-moving exteral formwork according to

de construction conditions. When the site condition does not allow

to remove the form traveller at the closure part which have to go

backwards to segment, the second type is suggested.

● Low gravity of front trancerse beam

● Applicable to large-scale stay-cable cantilever casting bridge with wide bridge deck

● Safe & easy operation, easy fixing, and safty during walking

● Big operational space under the main frame, and easy installation and removal

- Q: Hanging basket concrete pouring construction control points

- Management points:1 the concrete pouring on both sides of the beam should be symmetrical and balanced, and the unbalanced construction load should not be greater than the allowable value;2 concrete should be rapid, continuous construction, in the first pouring of concrete before the first pouring all completed;3 the bottom plate, the web and the roof are symmetrically layered, and the layer thickness should not be greater than 30cm;4 continuously change the height of the hanging basket in the process of concrete pouring;5 the quality of the installation of the prestressed channel, unobstructed inspection and plugging treatment;6 the vibration of concrete should meet the requirements of construction technology, it is appropriate to use high-frequency attachment vibrator with vibration;7 the temperature and air content of concrete in mold meet the design requirements;8 test specimens of concrete strength and elastic modulus.

- Q: DARK LEVEL 03Sign-Up: 11/04/07Posts: 171I always wanted my real life clan, tribe, band of gypsies, traveling commune, what ever the hell you want to call it.I always wanted to have my own group of way ward wanders that travel place to place together.I just think it would be nice to have that.Thoughts, comments, suggestions? Wanna join?

- I think you should sign up for International Living, many agents will guide you and lead you the way to your wanted life style in travelling for free all over this world. My parents do not allow me to join the groups.

- Q: Hanging basket construction continuous beam, the adjacent fast is how to connect, such as Block 0 and block No. 1

- 3, installation of connecting two adjacent segments (such as 0# and 1#, 0# and 1 "#) corrugated pipe hole, and wear long (such as 1# to 0# to 1" # through wearing steel strand).

- Q: Master, according to the whole process of analysis of the accounting process...... Did not do it, the specific process of each labor subcontracting costs are uncertain, give a train of thoughtThe key is the process unit price analysis process, not the comprehensive subcontracting guidance price. To help with micro letter envelopes......

- First, you need to determine what you need, I can help you analyze!

- Q: What is hanging basket construction

- Also known as cantilever filling method, refers to the bridge on both sides of the support (support) frame support, filling a certain length of the beam section (called Block 0)

- Q: When hanging blue construction, middle span closure, why must the counterweight

- The carrying capacity of the hanging basket depends on the maximum weight of the cast-in-place section

- Q: Vertical embedding of hanging basket

- Reinforcement and reserved holeIn the hanging basket after the anchor system of the embedded 32 finish rolling screws must be kept vertical, strict inspection in the management, so that the same axis

- Q: Construction technology of bridge hanging basket

- A, pillow and track installation;B, assembled hanging basket main frame;C, installing front cross member and front sling;D, the crane will be used to bridge the bottom of the bottom of the platform to lift the platform, and with the front sling, and then install the rear sling;

- Q: Hanging basket installation, removal of dangerous source identification

- In general, there may be hidden dangers of accidents, there may be no hidden dangers for the existence of hidden dangers of accidents must be timely rectification, otherwise it may lead to accidents.

- Q: Short platform pull rope type hanging basket

- 2, rhombic hanging basket structure and technical parameters2.1 rhombic hanging basket structure and technical parametersThe rhombic hanging basket is mainly composed of a rhombic truss, an upper cross beam, a bottom mould platform, a hanging system, a walking system, an anchoring system, a side mould, an internal mould and a bracket, etc.. Technical parameters: applicable to the largest segment of 400t; maximum segment length 4m; beam height of 4.822 ~ 2.5m; for Liang Kuan 37.4m; walking for walking without balance weight; weight hanging basket (including template and support) is 170t; the hanging basket overturning stability coefficient, concrete pouring for 3.2, walking when 11.

Send your message to us

Triangular Form Traveller in High Quality

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords