Custom SF63 Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

concrete column formwork

aluminium formwork system

Adjustable SF120 System for Rectangle / Square Concrete Column

Description:

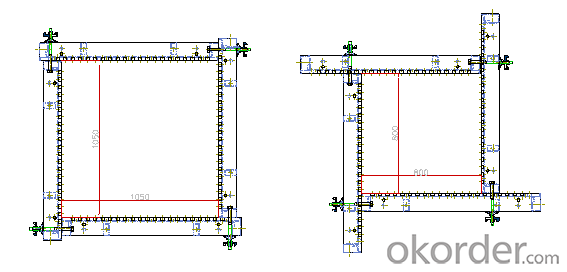

1. Structure sketch

SF120-A is a kind of formwork for pouring rectangle & square column; it is composed of formwork, props, adjustable steel clamp, etc.

Competitive Advantage:

1. High-precision production line guarantees the perfect products.

2. Special hollow steel frame covered with WISA-plywood, light weight but high strength.

Its allowable pressure from fresh concrete is 80KN/m2 with the weight of 65KG/m2.

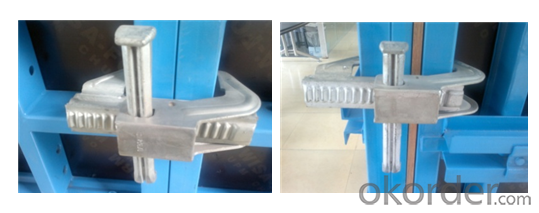

3. Easy connection with adjustable steel clamp.

4. The system is easy to change the cross section.

Applications:

- Q: Can steel frame formwork be used for both smooth and textured concrete finishes?

- Indeed, both smooth and textured concrete finishes can be achieved using steel frame formwork. With its flexibility and durability, the steel frame formwork proves to be appropriate for a wide range of concrete finishes. In terms of smooth finishes, the steel formwork ensures a rigid and stable structure, enabling the attainment of an accurate and uniform concrete surface. Conversely, for textured finishes, the steel formwork can be altered or combined with supplementary materials to produce desired patterns or textures on the concrete surface. All in all, the steel frame formwork provides a versatile answer to diverse finishing demands in concrete construction.

- Q: What are the different types of formwork anchors used with steel frame formwork systems?

- Steel frame formwork systems utilize various types of formwork anchors to provide stability and support during the concrete pouring process. Included in these anchors are loop ties, adjustable clamps, wedges, C-clamps, formwork brackets, formwork ties, and combination anchors. Loop ties serve as a popular choice for attaching formwork panels to the steel frame. They comprise a looped wire that is inserted through the formwork and securely fastened to the frame using tie rods or other fastening methods. To secure the formwork panels to the steel frame, adjustable clamps are employed. These clamps can be easily adjusted to accommodate different panel thicknesses, ensuring a tight and secure connection. Wedges are utilized to securely fasten formwork panels to the steel frame. These wedges are inserted into specially designed slots on the frame, providing a robust and steadfast connection. C-clamps, designed with a convenient C-shape, are utilized for attaching formwork panels to the steel frame. Due to their shape, these clamps effortlessly slide onto the frame, establishing a secure connection. Formwork brackets are employed to support the formwork panels and enhance stability. These brackets can be adjusted to the desired height and angle, and are attached to the steel frame. Formwork ties are used to connect multiple formwork panels together. These ties are inserted through the panels and securely fastened to the steel frame using tie rods or other fastening methods. Combination anchors offer versatility and can be used for various applications. These anchors integrate different elements, such as loops, clamps, and wedges, to establish a secure connection between the formwork panels and the steel frame. These examples represent only a fraction of the diverse formwork anchors employed in steel frame formwork systems. The selection of an appropriate anchor relies on factors such as formwork design, load requirements, and specific project needs. It is crucial to choose the correct anchor to ensure the stability and safety of the formwork during the concrete pouring process.

- Q: What are the safety considerations when using steel frame formwork?

- Several important safety considerations should be kept in mind when utilizing steel frame formwork. Firstly, it is crucial to ensure the proper design and construction of the steel frame formwork, ensuring its ability to withstand the loads and pressures exerted during concrete pouring. Any structural deficiencies or weaknesses in the formwork can pose significant safety risks to workers. In addition, workers should receive thorough training and education regarding the assembly, installation, and dismantling procedures specific to steel frame formwork. They must be familiar with the necessary safety measures and precautions, including the use of appropriate personal protective equipment (PPE) such as helmets and safety harnesses, as well as the correct procedures for securing the formwork to prevent collapse or movement. Another safety consideration is the potential for falls from height, as steel frame formwork is commonly used in tall structures. Proper fall protection measures, such as guardrails or safety nets, should be implemented to prevent workers from falling and sustaining serious injuries. Regular inspections of the steel frame formwork should also be conducted to identify any signs of damage or deterioration, such as cracks or rust. Prompt attention should be given to addressing these defects to ensure the integrity and safety of the formwork. Regular maintenance and repairs are essential to maintain the formwork's condition and its ability to safely support the concrete pouring process. Lastly, effective communication and coordination among the construction team are vital to ensure safety when using steel frame formwork. Clear instructions and procedures should be established and communicated to all workers involved in the installation and removal of the formwork. This will help minimize the risk of accidents and ensure that everyone understands their roles and responsibilities. Overall, adherence to proper design, training, inspection, and maintenance protocols, along with the implementation of appropriate fall protection measures, can effectively mitigate the safety risks associated with steel frame formwork. This will provide a secure working environment for all construction workers involved.

- Q: What are the different types of reinforcement systems used with steel frame formwork?

- There are several different types of reinforcement systems used with steel frame formwork in construction projects. These reinforcement systems are designed to provide additional strength and stability to the formwork, ensuring that it can withstand the weight and pressure of the concrete being poured. One common type of reinforcement system used with steel frame formwork is the use of steel bars or rods. These bars are typically placed horizontally and vertically within the formwork to create a grid-like pattern. This grid of steel bars helps to distribute the weight and pressure of the concrete evenly, preventing the formwork from collapsing or deforming. Another type of reinforcement system used with steel frame formwork is the use of steel mesh or wire. This mesh or wire is typically placed within the formwork to provide additional reinforcement and prevent the concrete from cracking or breaking under pressure. The mesh or wire is usually secured in place using ties or clips, ensuring that it remains in position during the pouring and curing process. In addition to steel bars and mesh, other reinforcement systems used with steel frame formwork include the use of fiber-reinforced polymers (FRPs) and plastic or composite materials. These materials are lightweight, yet strong, and can provide excellent reinforcement to the formwork. FRPs are often used in situations where corrosion resistance is required, as they are not susceptible to rust or degradation. Overall, the choice of reinforcement system used with steel frame formwork will depend on factors such as the specific project requirements, the type and load of the concrete being poured, and the desired level of strength and stability needed. It is important to consult with a structural engineer or construction professional to determine the most suitable reinforcement system for a particular project.

- Q: Can steel frame formwork be used in seismic zones?

- Yes, steel frame formwork can be used in seismic zones. Steel is known for its strength and durability, making it suitable for construction in areas prone to earthquakes. It provides the necessary stability and resistance required to withstand seismic forces, ensuring the safety and integrity of the structure.

- Q: What are the common material handling and storage practices for steel frame formwork systems?

- Common material handling and storage practices for steel frame formwork systems include ensuring proper lifting and handling techniques to prevent damage or injury, storing the components in a dry and protected area to prevent rust and corrosion, organizing and labeling the components for easy identification and retrieval, and implementing regular inspections and maintenance to ensure the formwork remains in good condition and ready for use.

- Q: Can steel frame formwork be used for the construction of dams?

- Indeed, it is true that dams can be constructed using steel frame formwork. Steel frame formwork is renowned for its versatility and adaptability, enabling the creation of intricate concrete structures such as dams. By providing the essential support and framework for pouring and contouring concrete, steel frame formwork guarantees that the dam is constructed according to the desired specifications and design. The durability, stability, and user-friendliness of steel frame formwork contribute to its suitability for extensive projects like dam construction. Furthermore, the modular characteristics of steel frame formwork facilitate effortless assembly, disassembly, and reusability, rendering it a cost-effective choice for dam construction endeavors that necessitate multiple pours and structures.

- Q: How does steel frame formwork contribute to the overall waterproofing of a concrete structure?

- Steel frame formwork does not directly contribute to the overall waterproofing of a concrete structure. A steel frame formwork is a temporary structure used during the construction process to shape and support the concrete until it sets and gains enough strength. It acts as a mold or a framework into which the concrete is poured, allowing it to take the desired shape and form. The primary function of steel frame formwork is to provide stability and support to the concrete during the pouring and curing stages. It ensures that the concrete maintains its shape and structure, preventing any deformation or collapse. Additionally, the steel frame provides a rigid framework that allows for accurate placement and alignment of the concrete, resulting in a structurally sound and stable final product. Waterproofing, on the other hand, is a separate process that is typically applied after the concrete has cured and the steel formwork has been removed. Waterproofing techniques involve the application of various materials or coatings to the concrete surface to prevent the penetration of water or moisture. These materials can include sealants, membranes, or special coatings designed to create a barrier against water ingress. While the steel frame formwork does not directly contribute to the waterproofing of a concrete structure, it indirectly supports the waterproofing process by ensuring that the concrete is properly shaped and cured. A well-constructed and properly supported concrete structure reduces the risk of cracks, voids, or other imperfections that could compromise the effectiveness of waterproofing measures. In this way, the steel frame formwork indirectly contributes to the overall durability and longevity of the waterproofing system in a concrete structure.

- Q: How does steel frame formwork ensure accurate dimensions and alignment?

- Steel frame formwork ensures accurate dimensions and alignment by providing a rigid and stable structure that holds the concrete in place during the construction process. The steel frames are precisely manufactured to the required dimensions, which helps in maintaining the shape and size of the concrete structure. Additionally, steel frame formwork allows for easy adjustment and alignment, ensuring that the concrete is poured accurately and in the desired position.

- Q: How does steel frame formwork ensure proper anchoring to the ground?

- Steel frame formwork ensures proper anchoring to the ground through several key features and techniques. Firstly, steel frame formwork is designed with sturdy steel frames that provide excellent stability and strength. These frames are securely anchored to the ground using a variety of methods such as steel stakes, ground anchors, or bolts. Additionally, steel frame formwork often includes adjustable legs or leveling screws, which allow for precise positioning and alignment on uneven ground surfaces. These adjustable elements ensure that the formwork is securely grounded and properly leveled, which is essential for achieving accurate and high-quality construction results. Moreover, steel frame formwork can also incorporate additional anchoring devices such as tie rods or braces, which further enhance its stability and resistance to external forces. These anchoring devices are strategically placed and secured to the ground, ensuring that the formwork remains firmly in place during the pouring and curing of concrete. Furthermore, steel frame formwork is often designed with integrated locking mechanisms or connection systems that provide a secure and rigid connection between individual formwork panels. This interlocking feature enhances the overall stability of the formwork system and prevents any lateral movement or displacement during the construction process. Overall, steel frame formwork is specifically engineered to ensure proper anchoring to the ground by combining robust steel frames, adjustable leveling mechanisms, anchoring devices, and interlocking systems. These features work in unison to provide a stable, secure, and reliable formwork system that can withstand the forces exerted during concrete pouring and curing, ultimately resulting in a structurally sound and well-built construction project.

Send your message to us

Custom SF63 Rectangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords