STEEL FRAMED FORMWORK AND ITS ACCESSORIES FOR BUILDING CONSTRUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

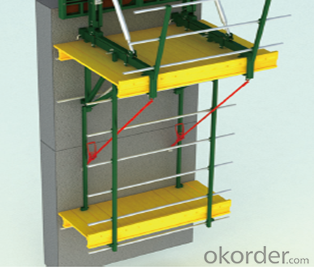

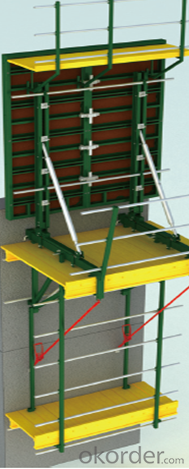

1. Structure of 120 Steel Framed Formwork Description

Single-side bracket is a kind of formwork for the concrete pouring of single-side wall. The construction is easy and fast. The components have good standard performance and versatility. The pouring height is adjustable, the maximum height of a single pouring is 8.9m.The formwork is always used in the concrete pouring of basement, subway, Sewage treatment factory and so on. The waterproof of the finished wall is excellent

2. Main Features of 120 Steel Framed Formwork

-easy to assemble

-simple structure.

-and convenient for transportation

-convenient for storage.

3. 120 Steel Framed Formwork Images

4. Single-side Steel Framed Formwork Specifications

5.FAQ of 120 Steel Framed Formwork

1) What can we do for you?

.We can ensure the quality of the 120 steel framed formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in single side steel framed formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Single side steel framed formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2 weeks.

- Q: What are the different methods of leveling and adjusting steel frame formwork?

- There are several methods of leveling and adjusting steel frame formwork, depending on the specific requirements of the construction project. Some of the most common methods include: 1. Jacking system: This method involves using hydraulic jacks to adjust the formwork to the desired level. The jacks are placed at strategic points along the frame and can be easily controlled to raise or lower the formwork as needed. 2. Wedges: Wedges are commonly used to level and adjust steel frame formwork. They are placed under the formwork at specific points and can be driven in or removed to achieve the desired level. Wedges offer a simple and effective way to make incremental adjustments. 3. Shims: Shims are thin, tapered pieces of material that are used to level and adjust formwork. They are typically made of metal or plastic and are placed between the formwork and the supporting structure to create a level surface. Shims can be stacked or removed as needed to achieve the desired level. 4. Screw jacks: Screw jacks are similar to hydraulic jacks but operate using a threaded rod mechanism. They can be easily adjusted by turning the rod clockwise or counterclockwise to raise or lower the formwork. Screw jacks are commonly used in conjunction with other leveling methods to fine-tune the formwork. 5. Leveling plates: Leveling plates are flat, steel plates that are used to distribute the load and level the formwork. They are placed under the formwork at strategic points and can be adjusted by adding or removing shims or wedges. Leveling plates provide a stable base for the formwork and ensure even distribution of weight. 6. Laser leveling: Laser leveling is a more advanced method that utilizes laser technology to achieve precise leveling. A laser level is set up at a reference point, and the formwork is adjusted based on the laser beam. This method is highly accurate and efficient, but it requires specialized equipment and expertise. In conclusion, there are various methods of leveling and adjusting steel frame formwork, ranging from simple manual techniques to advanced laser leveling. The choice of method depends on factors such as the project requirements, available resources, and desired level of accuracy.

- Q: How does steel frame formwork handle the placement of water and wastewater treatment systems within the concrete structure?

- When it comes to placing water and wastewater treatment systems within concrete structures, steel frame formwork is a versatile and reliable method. This formwork is designed specifically to handle the weight and pressure of these systems, ensuring their proper installation and long-term functionality. One of the main advantages of steel frame formwork is its strength and durability. Steel is known for its ability to bear heavy loads, making it the perfect choice for supporting the components of water and wastewater treatment systems. Furthermore, steel frame formwork adds stability and rigidity to the concrete structure, keeping it intact under the pressure exerted by these systems. Additionally, steel frame formwork offers flexibility in terms of customization. It can be easily adjusted and modified to fit the specific dimensions and requirements of the water and wastewater treatment systems. This allows for precise placement and alignment of pipes, tanks, and other components within the concrete structure, ensuring efficient operation and easy maintenance of these systems. Another advantage of steel frame formwork is its resistance to corrosion, which is crucial for the long-term durability and reliability of water and wastewater treatment systems. Steel is highly resistant to the corrosive nature of these systems, protecting the concrete structure from damage caused by chemicals and other corrosive elements. In addition to its strength and corrosion resistance, steel frame formwork is also easy to install and remove. It can be quickly assembled and disassembled, making construction and maintenance processes more efficient. This saves time and resources, making it a cost-effective solution for placing water and wastewater treatment systems within concrete structures. Overall, steel frame formwork is a robust and efficient method for placing water and wastewater treatment systems within concrete structures. Its strength, durability, flexibility, and resistance to corrosion make it the ideal choice for ensuring the proper installation and functionality of these systems, contributing to the success of water and wastewater treatment projects.

- Q: How does steel frame formwork affect the overall maintenance requirements of a structure?

- Steel frame formwork can significantly reduce the overall maintenance requirements of a structure. Its durable and robust nature allows it to withstand heavy loads, harsh weather conditions, and wear and tear over time. This reduces the need for frequent repairs and replacements, ultimately saving time and money on maintenance. Additionally, steel frame formwork provides a stable and sturdy support system, ensuring the structural integrity of the building, which further minimizes maintenance needs.

- Q: What are the different types of supports and props used with steel frame formwork?

- Steel frame formwork systems commonly utilize various types of supports and props to ensure stability and support. These components are crucial for proper formation and maintenance of the concrete structure throughout the construction process. Some examples of supports and props used in conjunction with steel frame formwork are as follows: 1. Adjustable Steel Props: Telescopic steel tubes that can be adjusted to different lengths are frequently employed to support horizontal formwork elements like beams and slabs. Their adjustable feature enables easy height adjustment and guarantees stability during concrete pouring. 2. Tripod Supports: These supports consist of three legs with adjustable heights and are used to support vertical formwork elements, such as columns and walls. Tripod supports offer stability and can be easily adjusted to accommodate various formwork heights. 3. Soldier Props: Vertical supports made of steel, soldier props are commonly used to support vertical formwork elements like walls. They are adjustable in height and provide stability. Soldier props are often used in conjunction with other supports to enhance reinforcement. 4. Scaffolding: Scaffolding is a temporary structure used to support workers and materials during construction. It is frequently employed alongside steel frame formwork systems to provide additional support and access to different areas of the structure. Scaffolding is usually constructed of steel or aluminum and can be easily assembled and disassembled. 5. Formwork Brackets: These brackets are used to support horizontal formwork elements, such as beams and slabs. They are typically attached to the structure using bolts or clamps and provide extra support and stability during concrete pouring. Formwork brackets are often adjustable to accommodate different formwork heights and configurations. 6. Wall Ties: Wall ties are used to hold formwork panels together and provide stability to vertical formwork elements like walls. Typically made of steel, they are secured to the formwork panels using nuts and bolts. Wall ties ensure the formwork panels remain in place during concrete pouring and curing. In summary, the diverse range of supports and props used with steel frame formwork systems are meticulously designed to offer stability, support, and flexibility during the construction process. These components are essential in maintaining the formwork in place, enabling the proper formation of concrete structures.

- Q: How does steel frame formwork handle the placement of architectural features and details within the concrete structure?

- Steel frame formwork provides a versatile and efficient solution for handling the placement of architectural features and details within a concrete structure. With its sturdy and rigid structure, steel frame formwork ensures the accuracy and precision required to incorporate various architectural elements seamlessly into the concrete design. One of the key advantages of steel frame formwork is its ability to mold and shape concrete according to the desired architectural features. The steel frames can be easily customized to accommodate different shapes, curves, and angles, allowing for the creation of intricate architectural details. This flexibility allows architects to unleash their creativity and bring their unique designs to life. Moreover, steel frame formwork provides excellent support and reinforcement for architectural features during the concrete pouring process. The strong steel frames create a stable structure that prevents any deformation or displacement of the architectural elements. This ensures that the features are accurately positioned and securely embedded within the concrete structure, minimizing the risk of future damage or deterioration. The precision and accuracy of steel frame formwork also contribute to the overall quality and aesthetics of the concrete structure. By providing a reliable and stable framework, the formwork enables the concrete to be poured with great precision, resulting in a smooth and uniform finish. This ensures that the architectural features are well-defined and visually appealing, enhancing the overall beauty and appeal of the structure. Additionally, steel frame formwork offers time and cost-saving benefits when it comes to incorporating architectural features. The modular nature of the steel frames allows for easy assembly and disassembly, reducing construction time and labor costs. This, in turn, facilitates the efficient placement of architectural details within the concrete structure. In conclusion, steel frame formwork plays a crucial role in handling the placement of architectural features and details within a concrete structure. Its versatility, strength, and precision allow for the seamless integration of various architectural elements, ensuring the creation of visually stunning and structurally sound concrete designs.

- Q: How does steel frame formwork contribute to faster construction times?

- Steel frame formwork contributes to faster construction times by providing a sturdy and reusable framework for pouring concrete. Its robust structure ensures quick and accurate assembly, allowing for efficient and precise concrete placement. Additionally, steel frame formwork can be easily adjusted and reused for multiple projects, reducing the need for frequent replacements and saving time on formwork preparation. The use of steel also minimizes the time required for formwork removal as it offers high strength and durability, enabling faster curing of concrete. Overall, steel frame formwork accelerates construction processes, leading to faster completion times.

- Q: How does steel frame formwork accommodate different shapes and sizes of concrete structures?

- Steel frame formwork is a versatile system that can easily adapt to different shapes and sizes of concrete structures. The steel frames can be easily adjusted and reinforced to create various configurations and dimensions, allowing for the construction of complex geometries. Additionally, the formwork panels can be customized and connected together to fit specific requirements, ensuring the accurate shaping of the concrete structure. This flexibility and adjustability of steel frame formwork make it an ideal choice for accommodating different shapes and sizes in concrete construction projects.

- Q: How does steel frame formwork handle the impact of vibrations during concrete pouring?

- Steel frame formwork is designed to handle the impact of vibrations during concrete pouring in a highly efficient manner. The steel structure provides excellent strength and rigidity, which helps to minimize the effects of vibrations. Additionally, the formwork is usually secured firmly to the ground or support structure, further enhancing its stability. During concrete pouring, vibrations are generated due to the pouring process itself, as well as the use of vibrating equipment to eliminate air pockets and ensure proper compaction. These vibrations can potentially cause the formwork to shift or become unstable, resulting in a compromised concrete structure. To counteract these vibrations, steel frame formwork often incorporates additional measures such as diagonal bracing or cross-bracing. These bracings help to reinforce the formwork system and distribute the vibrations more evenly, reducing the concentration of forces on any single point. Moreover, steel frame formwork is typically designed with adjustable components, allowing for precise alignment and leveling during the construction process. This adjustability enables the formwork to absorb and adapt to the vibrations, minimizing any potential impact on the concrete pouring. Overall, the robustness and stability of steel frame formwork make it well-suited to handle the impact of vibrations during concrete pouring. By providing a secure and rigid structure, alongside additional bracing and adjustability, steel frame formwork ensures that the concrete structure is not compromised, resulting in a high-quality and durable end product.

- Q: What are the common safety features incorporated in steel frame formwork systems?

- Incorporated within steel frame formwork systems are a range of common safety features, including: 1. Utilization of high-strength steel: The construction of steel frame formwork systems involves the use of durable and stable high-strength steel. This material possesses the ability to withstand heavy loads and extreme weather conditions, thereby reducing the likelihood of collapse or structural failure. 2. Integration of safety locks and latches: Steel frame formwork systems are equipped with secure safety locks and latches that firmly hold the formwork panels together. These locks serve to prevent accidental disassembly or movement of the panels, ensuring the safety of workers on the construction site. 3. Incorporation of a non-slip surface: Steel frame formwork systems often feature a surface that is resistant to slipping, thereby providing workers with improved traction while walking or working on the formwork. This serves to minimize the risk of slips, trips, and falls, particularly in wet or slippery conditions. 4. Provision of guardrails and handrails: Steel frame formwork systems can be outfitted with guardrails and handrails to provide workers with fall protection. These safety features help to prevent workers from inadvertently falling off the formwork structure, thus creating a safer working environment. 5. Integration of accessible platforms and ladders: Some steel frame formwork systems incorporate integrated access platforms and ladders, facilitating the safe and easy movement of workers between different levels of the structure. These features eliminate the need for hazardous or makeshift means of access, thereby reducing the risk of accidents. 6. Display of safety signage and markings: Steel frame formwork systems often include safety signage and markings that indicate potential hazards, safe load limits, and assembly instructions. These visual cues aid workers in understanding and adhering to safety protocols, thereby minimizing the risk of accidents and injuries. 7. Adherence to safety standards in design: Steel frame formwork systems are designed and manufactured in accordance with relevant safety standards and regulations. This ensures that the formwork system meets specific safety requirements, thus providing a higher level of protection for workers on the construction site. In summary, steel frame formwork systems incorporate a variety of safety features to safeguard the well-being of workers and minimize the occurrence of accidents and injuries. These features encompass high-strength steel construction, safety locks and latches, non-slip surfaces, guardrails and handrails, accessible platforms and ladders, safety signage and markings, and adherence to safety standards in design.

- Q: What are the different types of bracing systems used with steel frame formwork?

- Steel frame formwork can be equipped with various bracing systems to ensure stability and support during concrete pouring. Commonly used bracing systems for steel frame formwork include: 1. Lateral stability is achieved through the installation of horizontal bracing at regular intervals along the horizontal beams of the formwork system. This prevents buckling or collapse under the concrete's weight. 2. Vertical support is provided by vertical bracing, which is installed at regular intervals along the vertical columns of the formwork system. It prevents sagging or bending under the concrete's weight. 3. Diagonal bracing offers both lateral and vertical support. It is installed diagonally between the horizontal and vertical bracing elements, helping to distribute the load evenly and increase overall stability. 4. Additional stability is provided by cross bracing, where diagonal braces intersect each other in an "X" shape. This prevents twisting or rotation during concrete pouring. 5. Tension rods, installed vertically and horizontally, can be tightened to provide extra support. They enhance the overall strength and stability of the formwork. The choice of bracing system depends on factors such as formwork height, size, load requirements, and specific construction project needs. It is crucial to select a suitable bracing system that meets safety standards and is appropriate for the application at hand.

Send your message to us

STEEL FRAMED FORMWORK AND ITS ACCESSORIES FOR BUILDING CONSTRUCTION

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords