STEEL FRAMED FORMWORK FOR CONSTRUCTIONS ALL THE WORLD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

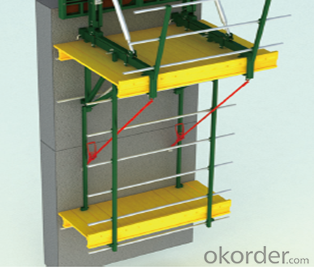

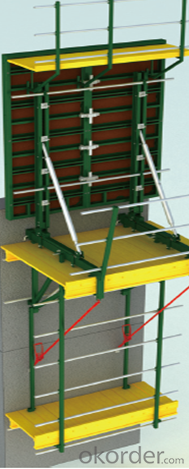

1. Structure of 120 Steel Framed Formwork Description

Single-side bracket is a kind of formwork for the concrete pouring of single-side wall. The construction is easy and fast. The components have good standard performance and versatility. The pouring height is adjustable, the maximum height of a single pouring is 8.9m.The formwork is always used in the concrete pouring of basement, subway, Sewage treatment factory and so on. The waterproof of the finished wall is excellent

2. Main Features of 120 Steel Framed Formwork

-easy to assemble

-simple structure.

-and convenient for transportation

-convenient for storage.

3. 120 Steel Framed Formwork Images

4. Single-side Steel Framed Formwork Specifications

5.FAQ of 120 Steel Framed Formwork

1) What can we do for you?

.We can ensure the quality of the 120 steel framed formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in single side steel framed formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Single side steel framed formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2 weeks.

- Q: How does steel frame formwork handle the placement of external cladding and façade materials within the concrete structure?

- Steel frame formwork is a versatile and efficient system for the construction of concrete structures, including the placement of external cladding and façade materials. This system provides several benefits that make the process easier and more manageable. Firstly, steel frame formwork provides a strong and stable framework for the placement of external cladding and façade materials. The steel frames are designed to withstand the pressure exerted by the concrete during pouring and ensure the structural integrity of the final product. This stability allows for the secure attachment of cladding and façade materials, ensuring they are properly aligned and fixed in place. Furthermore, the steel frames can be easily adjusted and customized to accommodate different types and sizes of cladding and façade materials. This flexibility allows for the precise placement of materials and ensures a seamless and aesthetically pleasing finish. Additionally, the steel frames can be easily dismantled and reassembled, allowing for easy access to the structure for maintenance or repairs in the future. Another advantage of steel frame formwork is its ability to provide a smooth and even surface for the placement of cladding and façade materials. The formwork system is designed to minimize any imperfections or irregularities in the concrete surface, ensuring a consistent and level base for the installation of materials. This results in a high-quality finish and enhances the overall appearance of the structure. Additionally, steel frame formwork allows for the integration of various construction techniques and materials, such as precast panels or curtain walls. This versatility enables the incorporation of different architectural design elements and aesthetics into the concrete structure. The steel frames can be easily adapted to accommodate the specific requirements of the cladding and façade materials, allowing for a seamless integration with the overall design concept. In conclusion, steel frame formwork provides a reliable and efficient solution for handling the placement of external cladding and façade materials within a concrete structure. Its strength, stability, flexibility, and ability to provide a smooth surface make it an ideal choice for ensuring the proper installation and integration of these materials, resulting in a high-quality and visually appealing finished product.

- Q: Can steel frame formwork be used in projects with limited availability of skilled labor?

- Yes, steel frame formwork can be used in projects with limited availability of skilled labor. Steel frame formwork is designed to be easy to assemble and dismantle, making it suitable for projects where skilled labor is limited. It requires minimal training and experience to install, reducing the reliance on highly skilled workers. Additionally, the durability and strength of steel frame formwork can handle the demands of construction projects, ensuring the safety and stability of the structures being built.

- Q: What is the typical lifespan of steel frame formwork accessories?

- The typical lifespan of steel frame formwork accessories can vary depending on various factors such as usage, maintenance, and quality of the materials. However, with proper care and regular maintenance, steel frame formwork accessories can last for many years, often exceeding 10 to 15 years or more.

- Q: How does steel frame formwork compare to plywood formwork?

- Two commonly used methods of construction formwork are steel frame formwork and plywood formwork, each having their own advantages and disadvantages. Durability is a major point of distinction between steel frame formwork and plywood formwork. Steel frame formwork is highly durable and can be reused multiple times, making it a cost-effective choice in the long run. Conversely, plywood formwork has a shorter lifespan and may require frequent replacements, resulting in higher costs. In terms of strength, steel frame formwork surpasses plywood formwork in load-bearing capacity. This makes it suitable for heavy-duty construction projects that require support for high loads. Plywood formwork, though not as strong, can still be effective for lighter construction projects. Another difference lies in the ease of assembly and disassembly. The modular design of steel frame formwork typically makes it easier to assemble and dismantle, leading to faster construction progress and increased efficiency. Plywood formwork, while generally straightforward to use, may require more time and effort for assembly and disassembly. Both steel frame formwork and plywood formwork offer advantages in terms of flexibility and versatility. Steel frame formwork can be easily adjusted to different shapes and sizes, making it suitable for complex construction designs. Plywood formwork, although less flexible, can still be adapted to various construction projects with appropriate modifications. When it comes to cost, steel frame formwork is generally more expensive upfront due to higher material and manufacturing costs. However, its long-term durability and reusability can offset these initial expenses. On the other hand, plywood formwork is initially more affordable but may require more frequent replacements, resulting in higher overall costs over time. Ultimately, the choice between steel frame formwork and plywood formwork depends on the specific requirements of the construction project. Factors such as load-bearing capacity, durability, flexibility, and cost must be carefully considered to determine the most suitable formwork method for a particular construction project.

- Q: What are the different types of formwork insulation solutions available for steel frame formwork systems?

- A variety of formwork insulation solutions are available for steel frame formwork systems, each designed to provide thermal insulation and prevent heat loss. Some commonly used types include: 1. Rigid insulation boards: These boards, made of materials like EPS, XPS, or PIR, come in different thicknesses and are placed between the steel frame and concrete formwork. They offer excellent thermal insulation and are easy to install and remove. 2. Insulating concrete formwork (ICF): ICF involves using insulated hollow blocks or panels as formwork. Made of EPS or XPS, these blocks or panels remain in place after concrete pouring, providing continuous insulation and eliminating the need for additional layers. 3. Spray foam insulation: Applied as a liquid, spray foam expands to fill the space between the steel frame and formwork. It adheres to surfaces, creating an effective air seal and thermal insulation. This type is ideal for hard-to-reach or irregular areas. 4. Reflective insulation: Comprising a layer of reflective material, like aluminum foil, sandwiched between insulation layers, this type reflects radiant heat away from the formwork system. It is easy to install and effectively reduces heat transfer. 5. Insulated formwork panels: These pre-fabricated panels incorporate insulation within the formwork system. Made of EPS or mineral wool, they provide both thermal insulation and structural support. They are lightweight, customizable, and easy to handle. To determine the most suitable formwork insulation solution for a steel frame formwork system, it is crucial to consider the project's specific requirements and consult with a qualified professional.

- Q: What are the different types of ties used with steel frame formwork?

- Steel frame formwork in construction projects commonly utilizes various types of ties. These ties play a crucial role in holding the formwork panels together and ensuring structural stability during the pouring and curing of concrete. 1. The most frequently employed ties in steel frame formwork are steel wedge ties. These ties consist of steel bars with wedge-shaped ends, which are inserted into the formwork panels and tightened using a wedge or pin. Due to their easy installation and removal, steel wedge ties are a popular choice. 2. Coil ties, on the other hand, are made of steel rods with helical coils present at one end. These ties are inserted through the formwork panels, and by turning the coils, the formwork is pulled tightly against the concrete. Coil ties are particularly advantageous for curved or irregularly shaped formwork. 3. Plate ties are flat steel plates with evenly spaced holes drilled into them. They are utilized alongside bolts or screws to securely fasten the formwork panels together. With their strong and reliable connection, plate ties are often employed in heavy-duty formwork applications. 4. For securing two parallel formwork panels together, shear ties, also known as snap ties, are used. These ties consist of metal bars with button-like ends that quickly snap into place, providing a secure and tight connection. Shear ties are commonly used in wall formwork due to their quick and easy installation. 5. Formwork clamps are designed to hold the formwork panels together at corners or joints. Typically made of steel, these clamps feature a clamping mechanism that securely locks the panels in place. Formwork clamps are versatile and can be adjusted to fit different panel thicknesses. Selecting the appropriate type of tie for a formwork project is crucial. Factors such as load capacity, formwork dimensions, and desired finish dictate the choice of tie. Consulting with a structural engineer or formwork specialist is highly recommended to ensure the correct ties are utilized for a specific steel frame formwork system.

- Q: My classmates is architecture design and construction, a two storey commercial pedestrian system in the original road, the main crowd and some small traders stall, shops can use lightweight materials enclosed, want to ask how to structure a good deal?

- If the use of lightweight materials to do wall and roof, I suggest the first floor of the steel frame structure

- Q: How does steel frame formwork handle different types of concrete curing techniques?

- Versatile and durable, steel frame formwork effectively manages a range of concrete curing methods. This system's stability and strength enable it to withstand the pressure and weight of the curing process. An example of a common curing technique is the traditional wet method. The steel frame formwork offers a secure and robust structure, ensuring the wet concrete retains its shape and does not deform or collapse during curing. Moreover, the frame helps regulate temperature and moisture levels, promoting optimal curing conditions. Another technique involves using curing compounds or membranes. These substances are applied to the concrete's surface to prevent moisture loss and facilitate proper curing. Steel frame formwork accommodates this method by providing a smooth and even surface for applying the compounds or membranes. It acts as a barrier, safeguarding against seepage into the ground and damage during curing. Furthermore, steel frame formwork is compatible with various accelerated curing techniques. These methods involve applying heat or other external factors to expedite the curing process. The steel frame can endure high temperatures, offering a stable structure for the concrete during accelerated curing. This ensures uniform and efficient curing, resulting in a sturdy and durable end product. In conclusion, steel frame formwork is designed to handle diverse concrete curing techniques. Its strength and stability enable it to support the weight and pressure of wet concrete during curing. Additionally, the formwork provides a smooth surface for applying curing compounds or membranes and can withstand the high temperatures associated with accelerated curing. All in all, steel frame formwork is a reliable choice for accommodating various concrete curing techniques.

- Q: How does steel frame formwork handle the placement of ramps and accessibility features within the concrete structure?

- Steel frame formwork is a versatile and efficient system that can easily accommodate the placement of ramps and accessibility features within a concrete structure. The steel frame formwork system consists of modular panels and adjustable props, which can be easily reconfigured to create the desired shape and dimensions required for ramps and other accessibility features. The panels of the steel frame formwork system are lightweight, yet sturdy, allowing for easy handling and installation. They can be easily adjusted to different heights and angles, making it possible to create ramps with varying slopes and inclinations. Additionally, the modular nature of the system allows for flexibility in design, enabling the inclusion of additional features such as handrails or non-slip surfaces to ensure the safety and accessibility of the structure. Furthermore, steel frame formwork provides excellent support and stability during the concrete pouring process. The adjustable props and tie rods ensure that the formwork remains in place and can withstand the pressure exerted by the wet concrete. This ensures that the ramp or any other accessibility feature is accurately formed and maintains its structural integrity. Moreover, steel frame formwork allows for efficient and easy removal once the concrete has cured and hardened. The formwork panels can be easily dismantled and reused for future construction projects, reducing waste and costs. This makes it a cost-effective and sustainable solution for incorporating ramps and accessibility features within a concrete structure. In conclusion, steel frame formwork is a highly adaptable and efficient system that effectively handles the placement of ramps and accessibility features within a concrete structure. Its modular design, adjustable components, and stability during the concrete pouring process make it an ideal choice for creating safe and accessible structures.

- Q: What is the typical lead time for manufacturing steel frame formwork?

- Manufacturing steel frame formwork usually takes varying lead times due to factors like design complexity, required quantity, raw material availability, and manufacturer's production capacity. On average, the lead time can span from a few weeks to a few months. It is crucial to note that the lead time encompasses design approval, fabrication, quality control, and transportation. Hence, it is recommended to consult the manufacturer or supplier to obtain a precise estimate tailored to your specific needs and circumstances.

Send your message to us

STEEL FRAMED FORMWORK FOR CONSTRUCTIONS ALL THE WORLD

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords