120 STEEL FRAMED FORMWORK FOR CONSTRUCTIONS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 120 Steel Framed Formwork Description

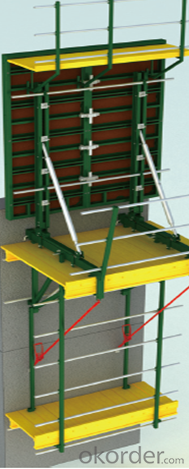

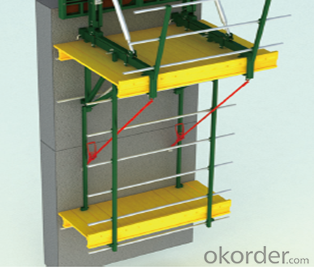

Single-side bracket is a kind of formwork for the concrete pouring of single-side wall. The construction is easy and fast. The components have good standard performance and versatility. The pouring height is adjustable, the maximum height of a single pouring is 8.9m.The formwork is always used in the concrete pouring of basement, subway, Sewage treatment factory and so on. The waterproof of the finished wall is excellent

2. Main Features of 120 Steel Framed Formwork

-easy to assemble

-simple structure.

-and convenient for transportation

-convenient for storage.

3. 120 Steel Framed Formwork Images

4. Single-side Steel Framed Formwork Specifications

5.FAQ of 120 Steel Framed Formwork

1) What can we do for you?

.We can ensure the quality of the 120 steel framed formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in single side steel framed formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Single side steel framed formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2 weeks.

- Q: How does steel frame formwork accommodate for different concrete mix proportions?

- Steel frame formwork can accommodate for different concrete mix proportions by providing adjustable panels and supports. These panels can be easily repositioned or modified to accommodate varying concrete mix proportions and ensure proper alignment and stability during the pouring and curing process. Additionally, the steel frame formwork system allows for precise control over the placement and compaction of the concrete, ensuring uniformity and strength regardless of the mix proportions used.

- Q: How does steel frame formwork handle concrete pouring in remote locations?

- Steel frame formwork is an ideal solution for concrete pouring in remote locations due to its durability, versatility, and ease of transportation. The steel frame formwork system provides a robust structure that can withstand the challenges of remote environments, ensuring the successful completion of construction projects. One of the key advantages of steel frame formwork is its ability to handle the pouring of concrete in remote locations is its durability. Steel is a strong and resilient material that can withstand the harsh conditions often associated with remote areas, such as extreme temperatures, high winds, and rough terrain. This durability ensures that the formwork structure remains intact during the concrete pouring process, preventing any potential failures or collapses that could compromise the project's success. Additionally, steel frame formwork offers great versatility, allowing for various shapes and sizes of concrete structures to be constructed in remote locations. The system can be easily customized to accommodate different project requirements, whether it involves constructing walls, columns, beams, or slabs. This adaptability ensures that the formwork can be efficiently utilized in any remote construction site, regardless of its unique characteristics or specifications. Transporting construction materials to remote locations can often be a logistical challenge. However, steel frame formwork is designed with portability in mind, making it easier to transport to remote construction sites. The lightweight yet sturdy nature of steel frame formwork enables it to be disassembled, packed, and transported to remote locations efficiently using various modes of transportation, such as trucks, boats, or helicopters. This ease of transportation reduces costs and time spent on logistics, ensuring that the formwork system can be readily available wherever it is needed. In conclusion, steel frame formwork is an excellent choice for handling concrete pouring in remote locations. Its durability, versatility, and portability make it a reliable and efficient solution for constructing concrete structures in challenging and hard-to-reach areas. By utilizing steel frame formwork, construction projects in remote locations can be completed successfully, meeting the desired specifications and standards.

- Q: Can steel frame formwork be used in projects with limited access to construction equipment?

- Construction projects with limited access to construction equipment can utilize steel frame formwork. This system is both versatile and durable, offering easy assembly and dismantling. Unlike other methods, it does not require heavy machinery or specialized equipment for installation. Instead, a small team of workers can manually handle the steel frames. Even in areas with restricted access, the lightweight steel frames can be transported to the project site without difficulty. They can be swiftly set up and adjusted, ensuring efficient construction progress. Furthermore, the frames can be reused multiple times, making them an economical choice for projects with limited access to construction equipment. In conclusion, steel frame formwork presents a practical and feasible solution for construction projects with restricted access to construction equipment. This enables the implementation of efficient and effective construction processes.

- Q: Can steel frame formwork be used for both small and large-sized concrete elements?

- Yes, steel frame formwork can be used for both small and large-sized concrete elements. Steel frame formwork is a versatile and robust system that is suitable for various construction projects. It can be easily adjusted and customized to accommodate different sizes and shapes of concrete elements. The use of steel frame formwork ensures high-quality and precise construction, allowing for efficient and cost-effective building processes. Additionally, steel frame formwork offers durability and reusability, making it an ideal choice for both small and large-scale projects.

- Q: How does steel frame formwork contribute to the overall cost of a construction project?

- Steel frame formwork can contribute to the overall cost of a construction project in several ways. Firstly, it may require a higher initial investment compared to other types of formwork, such as timber or aluminum. However, this cost is often justified by its durability and reusability, as steel formwork can withstand multiple uses without significant wear and tear. Additionally, steel formwork can help to expedite the construction process by allowing for faster assembly and disassembly, reducing labor costs. Moreover, its strength and stability can minimize the need for additional support structures, saving on material costs. Overall, while steel frame formwork may have a higher upfront cost, its efficiency and longevity can result in long-term cost savings for the construction project.

- Q: How is the quality of the concrete surface achieved with steel frame formwork?

- The use of steel frame formwork results in a high-quality concrete surface for several reasons. Firstly, the rigid and stable structure of steel frame formwork ensures that the fresh concrete is evenly poured and compacted, preventing any irregularities or deformations. Additionally, the design of steel frame formwork includes adjustable elements like clamps, tie rods, and spacers, which allow for precise alignment and leveling. This guarantees that the concrete is poured at the correct thickness and with consistent dimensions, resulting in a smooth and uniform surface. Furthermore, steel frame formwork often incorporates form liners or surface treatments that can create decorative patterns or textures on the concrete. These liners or treatments can be easily attached to the steel frames, enabling the creation of aesthetically pleasing finishes. Moreover, the durability and reusability of steel frame formwork are advantageous, especially in large construction projects. The ability to reuse the same formwork multiple times without compromising the quality of the concrete surface ensures uniformity throughout the project. In conclusion, the use of steel frame formwork ensures a high-quality concrete surface due to its stability, adjustability, and durability. These factors contribute to the creation of a smooth, even, and aesthetically pleasing surface that meets all required standards and specifications.

- Q: Can steel frame formwork be used in extreme weather conditions?

- Certainly! Steel frame formwork is capable of being utilized in even the most severe weather conditions. The durability and strength of steel have established its suitability for enduring inclement weather, encompassing extreme temperatures, heavy rainfall, forceful winds, and even snow. In contrast to alternative materials, steel frame formwork exhibits a diminished propensity for distortion, cracking, or deterioration when confronted with extreme weather conditions. Furthermore, steel formwork systems have been devised to facilitate effortless assembly and disassembly, permitting swift and efficient construction undertakings, even under arduous weather conditions. Nevertheless, it remains imperative to ensure that the steel frame formwork is adequately coated and safeguarded against corrosion, in order to preserve its longevity and performance amidst extreme weather conditions.

- Q: Can steel frame formwork be used for prefabricated concrete elements?

- Yes, steel frame formwork can be used for prefabricated concrete elements. Steel frame formwork provides a strong and durable structure that can support the weight of the concrete during the prefabrication process. It allows for precise and accurate shaping of the concrete elements, ensuring high-quality and consistent results. Additionally, steel frame formwork can be easily dismantled and reused for future projects, making it a cost-effective choice for prefabricated concrete elements.

- Q: How does steel frame formwork handle different types of formwork sealing techniques?

- The steel frame formwork system is highly versatile and robust, capable of effectively implementing various formwork sealing techniques. Its strength and stability ensure that it can withstand the pressure exerted by the concrete during pouring and curing. When it comes to formwork sealing techniques, the steel frame formwork system offers numerous advantages. Firstly, it provides a rigid and tight structure that prevents any concrete leakage. This is especially crucial when using liquid or flowable concrete mixes. The steel frame guarantees the integrity of the formwork, leaving no gaps or spaces for the concrete to escape. Secondly, the steel frame formwork system allows for the utilization of different sealing materials and techniques. For instance, rubber gaskets or seals can be used to create a watertight seal between the formwork and the structure. These gaskets are typically situated along the joints and edges of the formwork to prevent water or concrete seepage. Furthermore, the steel frame formwork system can accommodate the use of waterstops, which are placed within the formwork joints to prevent water penetration. These waterstops are commonly made of rubber or PVC and are highly effective in preventing any water leakage. Additionally, the steel frame formwork system can also incorporate the use of tie rods and formwork ties to ensure a secure and tight seal. These components are employed to tightly hold the formwork panels together, preventing any movement or displacement during concrete pouring. This helps to maintain the integrity of the formwork, guaranteeing its ability to handle various sealing techniques. To recap, the steel frame formwork system is well-equipped to handle different formwork sealing techniques. Its strength and stability create a solid structure that can endure the pressure from the concrete. Moreover, the flexibility of the steel frame allows for the utilization of different sealing materials and techniques, resulting in a watertight and secure formwork system.

- Q: How does steel frame formwork compare to traditional timber formwork in terms of durability?

- Steel frame formwork is generally more durable than traditional timber formwork. Steel is a strong and robust material that can withstand heavy loads and extreme weather conditions, making it highly resistant to warping, cracking, and decay. In contrast, timber formwork is more prone to wear and tear, such as rotting, splitting, and deformation over time. Therefore, steel frame formwork offers a longer lifespan and requires less maintenance, making it a more durable option for construction projects.

Send your message to us

120 STEEL FRAMED FORMWORK FOR CONSTRUCTIONS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords