55 SERIAL STEEL FRAMED FORMWORK FOR CONSTRUCTIONS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 120 Steel Framed Formwork Description

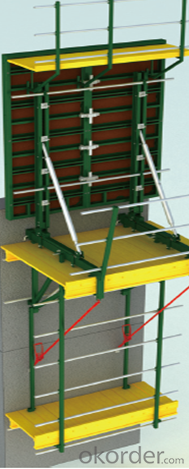

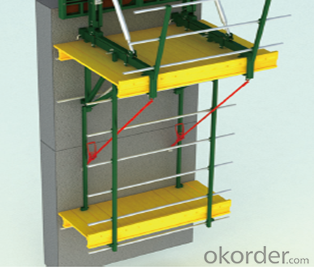

Single-side bracket is a kind of formwork for the concrete pouring of single-side wall. The construction is easy and fast. The components have good standard performance and versatility. The pouring height is adjustable, the maximum height of a single pouring is 8.9m.The formwork is always used in the concrete pouring of basement, subway, Sewage treatment factory and so on. The waterproof of the finished wall is excellent

2. Main Features of 120 Steel Framed Formwork

-easy to assemble

-simple structure.

-and convenient for transportation

-convenient for storage.

3. 120 Steel Framed Formwork Images

4. Single-side Steel Framed Formwork Specifications

5.FAQ of 120 Steel Framed Formwork

1) What can we do for you?

.We can ensure the quality of the 120 steel framed formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in single side steel framed formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Single side steel framed formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2 weeks.

- Q: What are the different types of formwork corners used in steel frame formwork systems?

- There are typically two types of formwork corners used in steel frame formwork systems: internal corners and external corners. Internal corners are used when the formwork needs to be supported from the inside, while external corners are used when the formwork needs to be supported from the outside. Both types of corners are designed to provide stability and reinforcement to the formwork structure, ensuring the proper alignment and stability of the concrete during the pouring and curing process.

- Q: How does steel frame formwork handle different types of formwork ties?

- Steel frame formwork is a versatile and durable construction system that is commonly used in various types of building projects. When it comes to handling different types of formwork ties, steel frame formwork offers flexibility and adaptability. Formwork ties are crucial elements in the construction process as they secure the formwork panels together, ensuring structural stability and shape retention during concrete pouring. Steel frame formwork is designed to accommodate different types of formwork ties, including snap ties, wedge bolts, and coil ties. Snap ties are commonly used in steel frame formwork due to their ease of use and quick installation. These ties consist of two separate parts that are snapped together, creating a strong connection between the formwork panels. Steel frame formwork can easily incorporate snap ties by providing suitable holes or slots in the frame members where the ties can be inserted and secured. Wedge bolts are another type of formwork tie that is compatible with steel frame formwork. These ties are inserted through holes in the formwork panels and secured with wedge plates or nuts. Steel frame formwork can be designed with pre-drilled holes or brackets to accommodate wedge bolts, ensuring proper alignment and tightness. Coil ties are used when there is a need for adjustable formwork ties. These ties consist of a coil rod that can be extended or shortened as required. Steel frame formwork can be designed with dedicated channels or brackets to hold coil ties securely in place. This allows for easy adjustment and repositioning of the formwork ties during the construction process. In summary, steel frame formwork is capable of handling different types of formwork ties by providing suitable provisions such as holes, slots, brackets, or channels. This ensures that the formwork ties can be securely attached to the steel frame formwork, providing the necessary structural support and shape retention during concrete pouring.

- Q: Can steel frame formwork be used for both internal and external concrete walls?

- Yes, steel frame formwork can be used for both internal and external concrete walls. The steel frame provides strength and stability, making it suitable for various construction applications. Additionally, the formwork can be easily adjusted and reused, making it a cost-effective solution for both internal and external walls.

- Q: Can steel frame formwork be used for both slab and foundation construction?

- Steel frame formwork is capable of being utilized for construction of both slabs and foundations. This versatile and resilient system allows for efficient construction of both slabs and foundations. It offers a robust and steady structure for concrete pouring and guarantees precise and accurate construction. The steel frame formwork system can be effortlessly assembled and disassembled, rendering it appropriate for a variety of project demands. Whether it involves a slab or foundation, steel frame formwork can be adapted and tailored to accommodate the particular requirements of the construction project.

- Q: Can steel frame formwork be used in earthquake-prone regions?

- In earthquake-prone regions, steel frame formwork is a suitable option. The strength and durability of steel make it more capable of withstanding seismic forces compared to materials like wood or concrete. The design of steel frame formwork systems prioritizes rigidity and robustness, ensuring stability and resistance to shaking during earthquakes. Furthermore, the assembly and disassembly of steel frame formwork are easily manageable, allowing for quick construction and reducing workers' exposure to potentially dangerous areas. This advantage becomes critical in earthquake-prone regions where prompt construction is necessary to restore damaged structures. Moreover, additional bracing and supports can reinforce steel frame formwork, further improving its ability to resist seismic activity. This is especially significant in areas with high levels of seismic activity, where buildings must withstand intense ground motions. However, it is important to acknowledge that although steel frame formwork offers a higher level of earthquake resistance than other materials, specific design and construction guidelines must be followed to ensure the safety and stability of structures. Collaborating with structural engineers and adhering to local building codes and regulations are vital to guarantee the appropriate use and implementation of steel frame formwork in earthquake-prone regions.

- Q: Can steel frame formwork be used for the construction of residential buildings?

- Yes, steel frame formwork can be used for the construction of residential buildings. Steel frame formwork offers several advantages such as high strength, durability, and flexibility in design. It provides a stable and efficient system for concrete placement, ensuring accurate and precise construction. Additionally, steel frame formwork can be easily assembled and disassembled, making it suitable for residential projects where time and cost efficiency are crucial.

- Q: How does steel frame formwork ensure proper alignment of columns and beams?

- Steel frame formwork ensures proper alignment of columns and beams through its rigid and accurate construction. The steel frame is precisely designed and manufactured to provide a strong and stable structure for the formwork system. Firstly, the steel frame formwork is designed to fit perfectly around the columns and beams, ensuring a tight and secure fit. This prevents any movement or shifting during the pouring and curing of concrete. The formwork is usually adjustable, allowing for easy alignment of the columns and beams to the desired position. This adjustability ensures that the formwork can accommodate different sizes and shapes of columns and beams. Additionally, the steel frame formwork provides a level and even surface for the concrete to be poured into. The formwork is usually equipped with adjustable metal props or jacks, which allow for precise adjustment of the height and level of the columns and beams. This ensures that the concrete is poured onto a level surface, preventing any unevenness or sloping in the final structure. Moreover, the steel frame formwork is designed to withstand the pressure and weight of the concrete during the pouring process. The steel frame is constructed with strong and durable materials, ensuring that it can support the weight of the concrete without any deformation or movement. This stability and rigidity of the formwork prevent any misalignment or distortion of the columns and beams. Overall, the steel frame formwork system ensures proper alignment of columns and beams by providing a rigid, adjustable, and level structure for pouring the concrete. It guarantees that the columns and beams are accurately positioned, resulting in a structurally sound and aesthetically pleasing final construction.

- Q: What is the role of tie rods and connectors in steel frame formwork?

- The tie rods and connectors in steel frame formwork serve to provide stability and support to the formwork system. They help to distribute the loads evenly across the framework, ensuring the structural integrity of the formwork during the concrete pouring process. Additionally, tie rods and connectors allow for easy adjustment and alignment of the formwork, enabling precise pouring and finishing of the concrete.

- Q: What are the different types of steel frame formwork available in the market?

- There are several types of steel frame formwork available in the market, including adjustable panel formwork, modular formwork, tunnel formwork, and climbing formwork. Each type offers unique advantages and is designed to meet specific construction requirements.

- Q: Can steel frame formwork be used in projects with high architectural finish requirements?

- Yes, steel frame formwork can be used in projects with high architectural finish requirements. Steel formwork provides a strong and durable structure that can hold the weight of concrete and provide the necessary support during construction. Additionally, steel formwork can be easily customized and adjusted to achieve precise and intricate architectural designs.

Send your message to us

55 SERIAL STEEL FRAMED FORMWORK FOR CONSTRUCTIONS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords