Steel Frame Formwork High Quality and Flexible GK120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

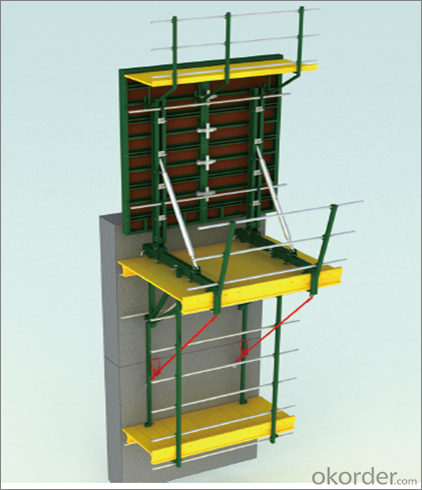

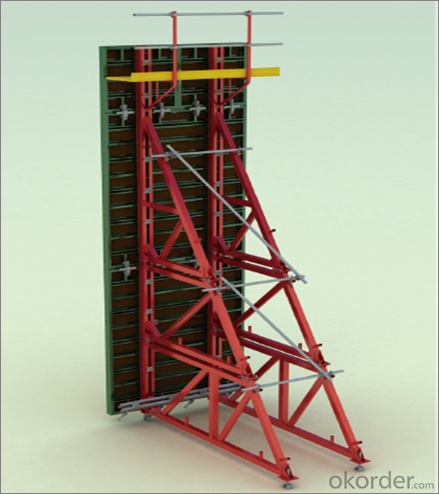

1. Structure of Steel Frame Formwork GK120

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q:How does steel frame formwork affect the overall sustainability goals of a construction project?

- Steel frame formwork can significantly contribute to the overall sustainability goals of a construction project. Firstly, steel is a highly durable and long-lasting material, ensuring that the formwork can be used repeatedly, reducing the need for frequent replacements and minimizing waste generation. Additionally, steel is recyclable, allowing for the formwork to be repurposed or recycled at the end of its lifecycle, thus reducing the environmental impact. Moreover, steel frame formwork provides structural stability and strength, enabling the construction of more efficient and sustainable buildings. By utilizing steel frame formwork, construction projects can achieve their sustainability goals by reducing waste, conserving resources, and creating more environmentally friendly structures.

- Q:How does steel frame formwork compare to traditional timber formwork?

- Steel frame formwork is a modern and efficient alternative to traditional timber formwork, making it a preferred choice in many construction projects due to several advantages it offers. Superior strength and durability are provided by steel frame formwork. Unlike timber formwork, which is susceptible to warping, shrinking, and swelling due to moisture, steel frame formwork remains stable and unaffected by weather conditions. As a result, a consistent and accurate formwork system is ensured, resisting deformation and resulting in a higher quality finished product. Another advantage is the versatility of steel frame formwork, which can be easily customized to suit different project requirements. It allows for easy adjustments and modifications, making it suitable for complex geometries and unique architectural designs. In contrast, timber formwork is limited in flexibility and requires more effort and time to adapt to various shapes and sizes. Steel frame formwork is also advantageous in terms of reusability. Unlike timber formwork, which has a limited lifespan before replacement, steel frame formwork can be reused for multiple projects. This not only reduces material waste but also offers long-term cost savings. Improved safety on construction sites is another significant advantage of steel frame formwork. Its rigid structure and secure connections provide better stability, reducing the risk of accidents and injuries. Additionally, steel formwork allows for easier access and maneuverability, enabling workers to carry out their tasks more efficiently and safely. Steel frame formwork also contributes to faster construction timelines. The simple and efficient assembly and disassembly process of steel formwork result in shorter construction cycles. This allows for increased productivity and reduced labor costs compared to traditional timber formwork, which requires more time and effort to set up and dismantle. Overall, steel frame formwork surpasses traditional timber formwork in terms of strength, durability, versatility, reusability, safety, and construction speed. Its numerous advantages make it a preferred choice for construction projects, saving both time and costs while ensuring high-quality results.

- Q:Do steel frame formwork systems require any additional support or reinforcement?

- It is common for steel frame formwork systems to require extra support or reinforcement in different construction projects. While these systems are generally strong and sturdy, they may need additional support to handle larger concrete loads or ensure stability during construction. There are various ways to provide this extra support or reinforcement. For instance, diagonal bracing can be used to strengthen the steel frame and prevent any potential deformation or collapse. Steel props or shoring systems may also be necessary to provide additional support to the formwork, especially when dealing with high concrete loads or large distances. In some cases, engineers may recommend using tie rods, walers, or other structural elements to reinforce the steel frame formwork system. These elements help evenly distribute the loads and provide the necessary stability during concrete pouring and curing. Ultimately, the need for additional support or reinforcement depends on specific project requirements, such as the size and complexity of the structure, the concrete loads involved, and the safety standards. It is vital to consult with a qualified structural engineer or construction professional to determine the appropriate level of support or reinforcement needed for a steel frame formwork system.

- Q:How does steel frame formwork ensure accurate dimensions and alignment of concrete structures?

- Steel frame formwork is a popular method used in construction to ensure accurate dimensions and alignment of concrete structures. It consists of a rigid steel frame that is designed and manufactured to the specific dimensions of the structure being built. One of the key ways steel frame formwork ensures accurate dimensions is through its precise fabrication process. The steel frame is manufactured to tight tolerances, ensuring that it is dimensionally accurate and consistent. This means that when the formwork is installed, it will provide a precise and uniform shape for the concrete to be poured into. Additionally, steel frame formwork is designed to be rigid and strong, which helps to maintain the alignment of the concrete structure. The frame is typically braced and supported in such a way that it resists any movement or deformation during the pouring and curing of the concrete. This prevents any shifting or misalignment of the formwork, which could result in inaccurate dimensions and compromised structural integrity. Furthermore, steel frame formwork often includes adjustable features that allow for fine-tuning and precise adjustments. For example, adjustable props or brackets can be used to ensure that the formwork is level and plumb, further enhancing the accuracy of the dimensions and alignment of the concrete structure. Overall, the use of steel frame formwork provides a reliable and effective method for achieving accurate dimensions and alignment in concrete structures. Its precise fabrication, rigidity, and adjustable features all contribute to ensuring that the final product meets the desired specifications and standards.

- Q:Can steel frame formwork be used for wastewater treatment plants?

- Wastewater treatment plants can indeed utilize steel frame formwork. This particular formwork option is both versatile and durable, capable of withstanding the harsh and corrosive conditions often encountered in such facilities. It provides a stable and rigid structure for the accurate and precise construction of concrete elements like tanks, channels, and basins. By employing steel frame formwork in wastewater treatment plants, numerous advantages can be gained. Firstly, the chemical and corrosion resistance of steel make it an ideal material for handling the aggressive nature of wastewater. This ensures the longevity and durability of the formwork, minimizing the need for frequent maintenance and repairs. Furthermore, steel frame formwork offers exceptional strength and stability, permitting the construction of large-scale structures within wastewater treatment plants. It can bear heavy loads and endure the pressures imposed by the concrete during casting and curing. Additionally, steel frame formwork allows for flexibility and adaptability in design and construction. It can be easily customized and adjusted to meet specific project requirements, accommodating diverse shapes and sizes of concrete structures. This versatility facilitates efficient and cost-effective construction processes. In conclusion, steel frame formwork represents a suitable and dependable choice for wastewater treatment plants. Its resistance to chemicals and corrosion, strength, stability, and flexibility make it an ideal option for constructing various elements in these environments.

- Q:How does steel frame formwork handle concrete curing in hot conditions?

- Steel frame formwork handles concrete curing in hot conditions by providing a stable and strong structure that can withstand the high temperatures. The steel frames are designed to hold the weight of the concrete and provide support during the curing process. In hot conditions, the steel frame formwork helps to regulate the temperature of the concrete by providing insulation. This prevents the concrete from drying out too quickly and ensures a more controlled curing process. The steel frames also help to reduce the risk of cracking or shrinkage due to the heat. Additionally, steel frame formwork allows for proper ventilation and air circulation around the concrete, which helps to dissipate excess heat and prevent the concrete from becoming too hot. This is important as excessive heat can cause thermal cracking and weaken the structure. Furthermore, steel frame formwork is highly durable and can withstand the expansion and contraction that occurs during the curing process in hot conditions. This ensures that the structure remains stable and secure. Overall, steel frame formwork is a reliable and effective solution for handling concrete curing in hot conditions. It provides the necessary support, insulation, and ventilation to ensure a successful and durable curing process.

- Q:Can steel frame formwork be used for both interior and exterior beam construction?

- Steel frame formwork is a versatile and robust system that can be used for both interior and exterior beam construction. Its strength and durability make it suitable for various construction projects, including beam construction. Furthermore, steel frame formwork offers flexibility in terms of shape and size, allowing for the construction of beams of different dimensions and designs. It is also easy to assemble and disassemble, which makes it a convenient choice for both interior and exterior beam construction. In summary, steel frame formwork is a reliable and efficient solution for beam construction, regardless of the location.

- Q:How does steel frame formwork contribute to better dimensional accuracy in precast elements?

- Better dimensional accuracy in precast elements is achieved through the use of steel frame formwork, which provides a strong and rigid structure that ensures precise and consistent shaping of the concrete. To begin with, the steel frame formwork is specifically designed and manufactured to meet dimensional requirements, ensuring its accuracy and enabling the creation of precise precast elements. The steel material's durability and stability prevent any deformation or movement during concrete pouring, which is crucial for maintaining correct dimensions. Additionally, the steel frame formwork offers a smooth and even surface for pouring the concrete, reducing the chances of irregularities or inconsistencies in the final product. It also allows for easy and precise adjustment of formwork components throughout the construction process, ensuring dimensional integrity. Furthermore, the steel frame formwork can be reused multiple times, making it a cost-effective solution for achieving dimensional accuracy in precast elements. By reusing the formwork, consistent and accurate dimensions can be achieved across multiple projects without the need for constantly creating new formwork. In conclusion, the use of steel frame formwork significantly contributes to better dimensional accuracy in precast element construction. Its strength, stability, and reusability ensure the accuracy of the formwork itself, while the smooth surface it provides allows for precise shaping of the concrete. By utilizing steel frame formwork, precast elements can be manufactured with consistent dimensions, resulting in high-quality and reliable structures.

- Q:Can steel frame formwork be used in marine or coastal construction?

- Yes, steel frame formwork can be used in marine or coastal construction. Steel is a durable and corrosion-resistant material that can withstand the harsh conditions present in marine environments. It provides the necessary strength and stability for concrete structures in coastal areas, making it a suitable choice for formwork.

- Q:How does steel frame formwork handle different types of reinforcement?

- Steel frame formwork is a versatile and efficient system that can easily handle different types of reinforcement in construction projects. The key advantage of steel frame formwork is its flexibility, allowing for the integration of various types of reinforcement, such as steel bars or mesh, without compromising the structural integrity of the formwork. The steel frame formwork is designed to accommodate and support the weight and pressure exerted by the reinforcement materials. It provides a sturdy and stable platform for the placement and installation of the reinforcement, ensuring that it remains in the desired position throughout the construction process. The formwork system also allows for easy adjustment and modification to accommodate different reinforcement configurations. The steel frames can be easily adapted to the required shape and size, allowing for the inclusion of different reinforcement layouts, such as vertical or horizontal bars, as well as various reinforcement spacings. Moreover, the steel frame formwork offers excellent durability and strength, which is crucial for handling different types of reinforcement. It can withstand the high loads and pressures exerted during concrete pouring and curing, ensuring that the reinforcement remains securely in place. Overall, the steel frame formwork system is well-equipped to handle various types of reinforcement in construction projects. Its flexibility, adaptability, and strength make it an ideal choice for contractors and engineers seeking to efficiently and effectively incorporate different reinforcement configurations into their construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Formwork High Quality and Flexible GK120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products