Adjustable SF120 System for Rectangle SF120-A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

concrete column formwork

aluminium formwork system

Adjustable SF120 System for Rectangle / Square Concrete Column

Description:

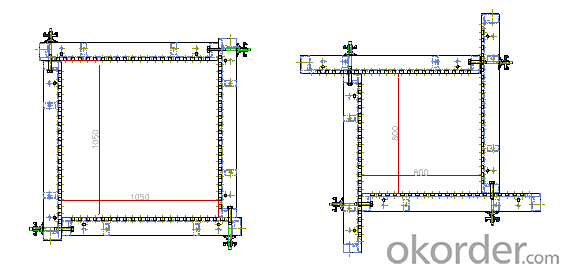

1. Structure sketch

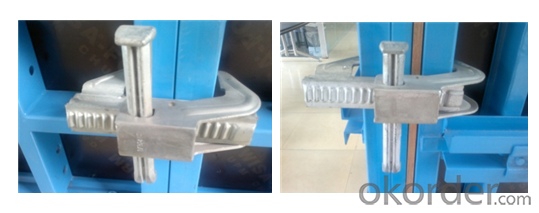

SF120-A is a kind of formwork for pouring rectangle & square column; it is composed of formwork, props, adjustable steel clamp, etc.

Competitive Advantage:

1. High-precision production line guarantees the perfect products.

2. Special hollow steel frame covered with WISA-plywood, light weight but high strength.

Its allowable pressure from fresh concrete is 80KN/m2 with the weight of 65KG/m2.

3. Easy connection with adjustable steel clamp.

4. The system is easy to change the cross section.

Applications:

Applications:

- Q: Can steel frame formwork be used in combination with other types of formwork systems?

- Indeed, steel frame formwork has the capability to be utilized alongside various other formwork systems. This particular formwork system offers a robust and long-lasting framework for concrete placement, enabling the creation of diverse shapes and sizes. It can be employed in conjunction with different formwork systems, such as timber formwork, aluminum formwork, or plastic formwork, in order to enhance the efficiency and versatility of the construction process. By amalgamating different formwork systems, construction experts can capitalize on the distinctive features provided by each individual system. For instance, steel frame formwork offers exceptional load-bearing capacity and stability, which makes it suitable for large-scale projects or structures with intricate geometries. Conversely, timber formwork may prove to be more economical and manageable for smaller projects or when a specific surface finish is desired. The amalgamation of steel frame formwork with other formwork systems grants greater flexibility and adaptability in construction projects. This allows contractors to customize the formwork design according to the specific requirements of each section of the structure, thus optimizing resource utilization and reducing construction time. However, when utilizing a combination of formwork systems, it is imperative to ensure compatibility and proper integration between the various components. This can be achieved through meticulous planning, coordination, and supervision, guaranteeing the stability and safety of the formwork structure. To conclude, steel frame formwork can effectively be employed in conjunction with other types of formwork systems, affording construction professionals a wider array of options to meet the specific needs of each project.

- Q: How does steel frame formwork handle concrete pouring in congested areas?

- Steel frame formwork is an efficient and versatile system used for concrete pouring in congested areas. It offers several advantages that enable it to handle such situations effectively. Firstly, the steel frame formwork is highly adaptable and can be customized to fit the specific requirements of the congested area. It can be easily adjusted, allowing it to be used in tight spaces and irregular shapes. This flexibility ensures that the formwork can be installed and used seamlessly, even in areas with limited accessibility. Additionally, steel frame formwork is lightweight yet strong, making it easier to handle and transport within congested areas. Its lightweight nature allows for quick assembly and dismantling, saving time and effort during the construction process. Furthermore, the strength of the steel frame ensures stability and durability, even under the pressure of concrete pouring. Moreover, the steel frame formwork system is designed to provide a smooth and uniform surface finish. This is particularly beneficial in congested areas where space is limited, as it eliminates the need for additional finishing work, such as plastering or rendering. The system also allows for easy placement of reinforcement bars, ensuring proper reinforcement throughout the structure. In terms of safety, steel frame formwork ensures a secure working environment for construction workers in congested areas. It provides a stable platform for pouring concrete, reducing the risk of accidents or injuries during the construction process. Additionally, the system is designed to prevent leakage and seepage of concrete, ensuring that the pouring process is efficient and effective. In conclusion, steel frame formwork is an ideal solution for handling concrete pouring in congested areas. Its adaptability, lightweight yet strong construction, smooth finishing capabilities, and safety features make it a reliable choice for construction projects that require efficient concrete pouring in tight spaces.

- Q: Can steel frame formwork be used for both single-storey and multi-storey structures?

- Yes, steel frame formwork can be used for both single-storey and multi-storey structures. Steel frame formwork is a versatile and durable system that can be easily adjusted to accommodate different heights and configurations. It provides excellent strength and stability, making it suitable for high-rise buildings and structures with multiple floors. Additionally, steel frame formwork allows for efficient and rapid construction, reducing project timelines and costs. Therefore, it is commonly used in both single-storey and multi-storey construction projects.

- Q: How does steel frame formwork ensure accurate dimensions and alignment of concrete structures?

- Achieving accurate dimensions and alignment in concrete structures is a common practice in construction, and steel frame formwork is a popular method used for this purpose. This method involves using a rigid steel frame that is specifically designed and manufactured to match the dimensions of the structure being built. An important aspect of steel frame formwork that ensures accurate dimensions is its precise fabrication process. The steel frame is manufactured with tight tolerances, guaranteeing dimensional accuracy and consistency. When the formwork is installed, it provides a precise and uniform shape for the concrete to be poured into. Moreover, the rigidity and strength of steel frame formwork play a significant role in maintaining the alignment of the concrete structure. The frame is typically supported and braced in a way that prevents any movement or deformation during the pouring and curing process. This prevents any shifting or misalignment of the formwork, which could compromise the structural integrity and lead to inaccurate dimensions. In addition to its rigidity, steel frame formwork often incorporates adjustable features that allow for fine-tuning and precise adjustments. For instance, adjustable props or brackets can be utilized to ensure that the formwork is level and plumb, further enhancing the accuracy of the dimensions and alignment of the concrete structure. In conclusion, the use of steel frame formwork is a reliable and effective approach to achieve accurate dimensions and alignment in concrete structures. Its precise fabrication, rigidity, and adjustable features all contribute to ensuring that the final product meets the desired specifications and standards.

- Q: Can steel frame formwork be used for both single-sided and double-sided concrete pouring?

- Yes, steel frame formwork can be used for both single-sided and double-sided concrete pouring. The steel frame provides strong support and stability, allowing it to withstand the pressure of the concrete from either one or both sides during pouring. This versatility makes steel frame formwork a suitable choice for various construction projects requiring different pouring methods.

- Q: How does steel frame formwork handle architectural features such as openings and recesses?

- Steel frame formwork is highly versatile and can easily handle architectural features such as openings and recesses. It allows for customization and precision in design, enabling the creation of various shapes and sizes. The steel frames can be easily adjusted, modified, or removed to accommodate specific architectural features, ensuring a seamless integration of openings and recesses within the overall structure.

- Q: What are the principles of the layout and spacing of steel structure engineering framework

- Square column and rectangular column is the basic column of multi story frame structure commonly used, the column should be used in 6 ~ 9m.When the column is determined, the grillage naturally according to the column grid layout. The main beam of the frame should be arranged on the frame column according to the frame direction.Generally need to be installed in the main beam according to the requirements of the floor beam, the spacing can be 3 ~ 4m.

- Q: Can steel frame formwork be used for wastewater treatment plants?

- Wastewater treatment plants can indeed utilize steel frame formwork. This particular formwork option is both versatile and durable, capable of withstanding the harsh and corrosive conditions often encountered in such facilities. It provides a stable and rigid structure for the accurate and precise construction of concrete elements like tanks, channels, and basins. By employing steel frame formwork in wastewater treatment plants, numerous advantages can be gained. Firstly, the chemical and corrosion resistance of steel make it an ideal material for handling the aggressive nature of wastewater. This ensures the longevity and durability of the formwork, minimizing the need for frequent maintenance and repairs. Furthermore, steel frame formwork offers exceptional strength and stability, permitting the construction of large-scale structures within wastewater treatment plants. It can bear heavy loads and endure the pressures imposed by the concrete during casting and curing. Additionally, steel frame formwork allows for flexibility and adaptability in design and construction. It can be easily customized and adjusted to meet specific project requirements, accommodating diverse shapes and sizes of concrete structures. This versatility facilitates efficient and cost-effective construction processes. In conclusion, steel frame formwork represents a suitable and dependable choice for wastewater treatment plants. Its resistance to chemicals and corrosion, strength, stability, and flexibility make it an ideal option for constructing various elements in these environments.

- Q: Can steel frame formwork be used for both single-story and multi-story buildings?

- Yes, steel frame formwork can be used for both single-story and multi-story buildings. Steel frame formwork is a versatile and durable construction technique that can be easily adapted to various building heights and designs. It provides stability and strength, making it suitable for structures of different sizes and complexities.

- Q: What are the different types of formwork clamps used with steel frame formwork?

- There are several different types of formwork clamps that are commonly used with steel frame formwork. These clamps are designed to securely hold the formwork panels in place and ensure that they do not shift or move during the concrete pouring process. One type of formwork clamp that is often used with steel frame formwork is the wedge clamp. This type of clamp consists of a metal wedge that is inserted into a slot on the formwork panel and then tightened to secure the panel in place. The wedge clamp is easy to use and can be quickly adjusted or removed as needed. Another type of formwork clamp that is commonly used with steel frame formwork is the hook clamp. This type of clamp consists of a metal hook that is inserted into a hole on the formwork panel and then tightened to secure the panel in place. The hook clamp provides a strong and secure connection between the formwork panel and the steel frame. In addition to wedge and hook clamps, there are also other types of clamps that can be used with steel frame formwork. These include spring clamps, which use a spring mechanism to hold the formwork panels in place, and toggle clamps, which use a lever mechanism to securely fasten the panels. These clamps can be easily adjusted and provide a strong and reliable connection between the formwork panels and the steel frame. Overall, the different types of formwork clamps used with steel frame formwork provide a variety of options for securely holding the formwork panels in place. Each type of clamp has its own advantages and disadvantages, and the choice of clamp will depend on the specific requirements of the construction project.

Send your message to us

Adjustable SF120 System for Rectangle SF120-A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords