Tabel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

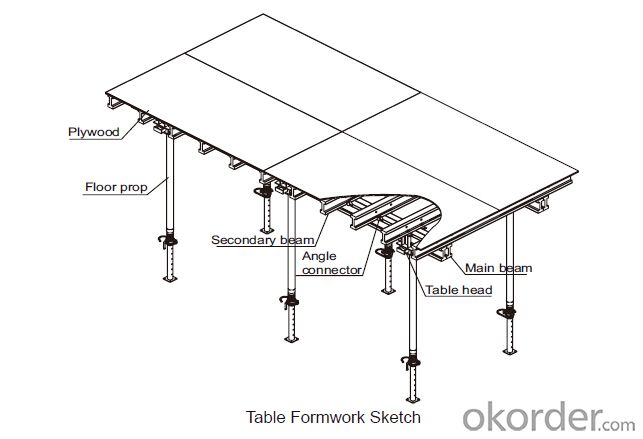

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q: Can steel frame formwork be used in projects with limited construction site water supply or drainage systems?

- Projects with limited construction site water supply or drainage systems can utilize steel frame formwork. This system is both versatile and durable, making it suitable for various construction projects. Unlike traditional timber formwork, steel frame formwork does not depend on water for stability and strength. With its self-supporting design, steel frame formwork can be easily assembled and disassembled. This makes it a great option for projects with limited water supply or drainage systems. Additionally, it can withstand high pressures and is ideal for projects requiring higher concrete pouring rates. Moreover, steel frame formwork is reusable, reducing construction costs and waste generation. It can be utilized multiple times across different projects. In summary, steel frame formwork is a practical choice for projects with limited construction site water supply or drainage systems. Its versatility, strength, and reusability make it a reliable solution for various construction needs.

- Q: How does steel frame formwork handle concrete curing in different weather conditions?

- Steel frame formwork is a flexible and long-lasting system utilized in the construction of concrete. It has been engineered to accommodate the curing process of concrete in diverse weather conditions. During hot weather, steel frame formwork prevents excessive moisture evaporation from the concrete surface. The steel frames establish a rigid structure that securely holds the concrete, preventing any cracks induced by rapid drying. Additionally, the steel formwork can be effortlessly insulated to maintain the necessary temperature for appropriate concrete curing, even in extreme heat. In cold weather, steel frame formwork safeguards the concrete against freezing. The steel frames act as a protective barrier, shielding the concrete from low temperatures and preventing freezing during the curing process. Moreover, insulation materials can be incorporated into the steel formwork to enhance its thermal efficiency, guaranteeing proper concrete curing even in freezing temperatures. In rainy or humid weather conditions, steel frame formwork is equipped with watertight seals to prevent water infiltration into the concrete structure. This is essential as excessive moisture can weaken the concrete and undermine its strength. The steel formwork, in combination with waterproof membranes and sealants, establishes a defensive barrier against water intrusion, enabling effective concrete curing. In summary, steel frame formwork is meticulously designed to accommodate various weather conditions throughout the concrete curing process. Its robust construction and ability to withstand extreme temperatures and moisture ensure proper concrete curing, resulting in a resilient and long-lasting structure.

- Q: Can steel frame formwork be used for both square and rectangular column construction?

- Certainly! Steel frame formwork is suitable for constructing both square and rectangular columns. This system, known for its versatility and flexibility, can adapt to various column sizes and shapes. It comprises steel frames and plywood sheets, which can be effortlessly assembled and disassembled to achieve the desired column configuration. The steel frames provide the required structural support and stability, while the plywood sheets serve as the formwork surface. As a result, square and rectangular columns can be effortlessly constructed. Moreover, steel frame formwork offers numerous benefits, including excellent reusability, durability, and the ability to achieve precise column measurements.

- Q: How does steel frame formwork contribute to the overall constructability of a concrete structure?

- The overall constructability of a concrete structure is greatly improved by the inclusion of steel frame formwork. Its impact can be observed in various key areas. To begin with, pouring and shaping the concrete is made easier and more reliable with the use of steel frame formwork. The steel frames are specifically engineered to withstand the pressure exerted by the liquid concrete, ensuring that it maintains its shape and integrity throughout the pouring process. This stability is crucial for achieving precise and accurate dimensions in the final structure. Moreover, the construction process becomes more efficient and speedy with the utilization of steel frame formwork. Its modular design allows for easy assembly and disassembly, reducing the time required for installing and removing the formwork. This time-saving aspect is particularly advantageous for large-scale construction projects, where the ability to quickly relocate the formwork from one area to another can significantly expedite the overall construction timeline. Additionally, steel frame formwork offers flexibility and adaptability during the construction phase. The modular components can be adjusted and reconfigured to meet various architectural and design requirements. This versatility enables the creation of complex structures with unique shapes and dimensions. Furthermore, the utilization of steel frame formwork contributes to the overall safety of the construction site. The robustness of the steel frames ensures that the formwork can withstand external forces such as wind or vibrations, reducing the risk of accidents or collapse. Furthermore, the use of steel formwork eliminates the need for excessive propping, further enhancing the safety of the construction site. In conclusion, steel frame formwork significantly improves the constructability of a concrete structure by providing stability, efficiency, flexibility, and safety. Its durable framework, modular design, and adaptability contribute to the accurate and timely construction of high-quality concrete structures.

- Q: How does steel frame formwork contribute to better formwork stability in windy coastal areas?

- Steel frame formwork contributes to better formwork stability in windy coastal areas due to its inherent strength and rigidity. Compared to traditional timber formwork, steel frame formwork is more resistant to strong winds and can withstand the forces exerted by coastal winds without shifting or collapsing. This enhanced stability ensures that the formwork remains intact, allowing for efficient and safe construction processes in these challenging conditions.

- Q: What type of concrete finishes can be achieved with steel frame formwork?

- Steel frame formwork offers versatility and durability, making it capable of producing various concrete finishes. This formwork system enables the creation of smooth, textured, and decorative finishes. Smooth finishes are commonly achieved using steel frame formwork. The rigid steel frames ensure that the concrete is poured and compacted evenly, resulting in a smooth and uniform surface. This finish is ideal for areas that require a clean and polished appearance, such as walls, ceilings, and floors. In addition to smooth finishes, steel frame formwork can also be utilized to create textured finishes. By incorporating different patterns or textures onto the surface of the formwork, the concrete can be cast with a textured finish. This includes patterns like brickwork or wood grain, providing aesthetic enhancement to architectural elements like facades, columns, or decorative walls. Moreover, steel frame formwork facilitates the creation of decorative finishes. These finishes involve adding special coatings, pigments, or aggregates to the concrete mix to achieve a desired appearance. The steel frames provide the necessary support for intricate designs, shapes, or patterns. Decorative finishes are commonly used in high-end projects such as museums, galleries, or luxury residences, where aesthetics are of great importance. In conclusion, steel frame formwork offers a wide range of possibilities for concrete finishes. Whether it be smooth and even surfaces or textured and decorative finishes, this formwork system provides the necessary support and flexibility to meet various design requirements.

- Q: What is the maximum permissible load on steel frame formwork support systems?

- The maximum permissible load on steel frame formwork support systems can vary depending on several factors, including the specific design and construction of the support system, as well as the intended use and load requirements of the formwork. Generally, steel frame formwork support systems are designed to withstand significant loads, as they need to support the weight of the formwork, concrete, and any additional loads imposed during the construction process. However, it is important to consult the manufacturer's specifications and guidelines for the specific support system being used, as they will provide the most accurate information regarding the maximum permissible load. Additionally, it is crucial to consider the load distribution and ensure that the load is evenly distributed across the support system to prevent any localized stress points or overloading. Proper engineering and structural analysis should be carried out to determine the maximum permissible load on the steel frame formwork support systems for a particular construction project. Ultimately, it is recommended to consult with a qualified structural engineer or the manufacturer of the support system to determine the maximum permissible load for a specific steel frame formwork support system, taking into account the project's requirements and specifications.

- Q: Can steel frame formwork be used in projects with limited project duration or tight schedules?

- Yes, steel frame formwork can be used in projects with limited project duration or tight schedules. Steel frame formwork offers several advantages that make it suitable for fast-paced construction projects. Firstly, steel frame formwork is lightweight and easy to handle, making it quick to assemble and dismantle. This can help save time during the construction process. Additionally, steel frame formwork is highly durable and can withstand multiple uses, which is beneficial for projects with tight schedules as it allows for faster concrete pouring and formwork re-use. Furthermore, steel frame formwork is adjustable and versatile, allowing for flexibility in design and layout changes, which can be crucial in projects with limited project duration. Overall, the use of steel frame formwork can contribute to increased productivity, reduced construction time, and improved efficiency in projects with limited project duration or tight schedules.

- Q: How does steel frame formwork handle the impact of vibrations during concrete pouring?

- Steel frame formwork is designed to handle the impact of vibrations during concrete pouring in a highly efficient manner. The steel structure provides excellent strength and rigidity, which helps to minimize the effects of vibrations. Additionally, the formwork is usually secured firmly to the ground or support structure, further enhancing its stability. During concrete pouring, vibrations are generated due to the pouring process itself, as well as the use of vibrating equipment to eliminate air pockets and ensure proper compaction. These vibrations can potentially cause the formwork to shift or become unstable, resulting in a compromised concrete structure. To counteract these vibrations, steel frame formwork often incorporates additional measures such as diagonal bracing or cross-bracing. These bracings help to reinforce the formwork system and distribute the vibrations more evenly, reducing the concentration of forces on any single point. Moreover, steel frame formwork is typically designed with adjustable components, allowing for precise alignment and leveling during the construction process. This adjustability enables the formwork to absorb and adapt to the vibrations, minimizing any potential impact on the concrete pouring. Overall, the robustness and stability of steel frame formwork make it well-suited to handle the impact of vibrations during concrete pouring. By providing a secure and rigid structure, alongside additional bracing and adjustability, steel frame formwork ensures that the concrete structure is not compromised, resulting in a high-quality and durable end product.

- Q: How does steel frame formwork affect the overall sound insulation of a concrete structure?

- Steel frame formwork can have a significant impact on the overall sound insulation of a concrete structure. The use of steel frames in formwork construction can create a more rigid and stable structure compared to traditional wooden formwork. This increased rigidity helps to minimize vibrations and sound transmission through the structure. One of the main factors affecting sound insulation in a concrete structure is the transmission of airborne sound waves. The rigid steel frame formwork provides a more solid barrier for these sound waves, reducing their ability to pass through the structure. This can greatly enhance the sound insulation performance of the concrete structure. Furthermore, steel frame formwork can also contribute to the reduction of impact noise. Impact noise is created by vibrations transmitted through the structure due to activities such as footfall, moving objects, or machinery. The use of steel frames helps to minimize these vibrations, resulting in reduced impact noise transmission. It is important to note that while steel frame formwork can enhance sound insulation, other factors such as the thickness and density of the concrete, the presence of additional insulation materials, and the overall design and construction of the structure also play a significant role. Therefore, it is essential to consider a comprehensive approach to sound insulation in concrete structures, taking into account all relevant factors.

Send your message to us

Tabel Formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords