various kinds of plastic formworks newly used

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Plastic Formwork:

More and more people in the world would like to importPlasticformwork from China since recentyears. Plastic formwork is a new type construction material in the construction industry andpeople could buy good quality at a very good price from Chinese market. In this way, the distributors make more profit and the end users could save more cost. Before you decide to purchase this kind of plastic formwork, you need to know how plastic formwork sprung up and grasped the market.The biggest panel is 120x60cm, weight only 10.5kg, which can be lift and set up by only one person easily, need no crane on the site.

2. The Advantages of Plastic Formwork:

1:easy set up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the

system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

2:modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls

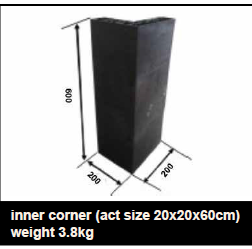

and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls120x60 panel (act size 120x60cm) of multiple by 5cm. The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

3:strength

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

4:friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment.

5:consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

4. FAQ of Plastic Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

- Q:How does steel frame formwork contribute to the overall structural integrity of a concrete structure?

- Steel frame formwork contributes to the overall structural integrity of a concrete structure by providing a strong and rigid support system for the concrete during the pouring and setting process. It ensures that the concrete is evenly distributed, prevents any sagging or deformation, and allows for accurate shaping and alignment of the structure. Additionally, the steel frame formwork helps to resist external forces such as wind and earthquake loads, enhancing the durability and stability of the concrete structure over time.

- Q:Can steel frame formwork be used in projects with limited construction site lighting or visibility conditions?

- Yes, steel frame formwork can be used in projects with limited construction site lighting or visibility conditions. Steel frame formwork is highly durable and provides a sturdy structure for concrete pouring. It is designed to withstand heavy loads and can be used in various construction projects. In projects with limited lighting or visibility, steel frame formwork can still be used effectively with the help of additional lighting sources, such as portable lighting equipment or construction site lighting towers. These lighting sources can be strategically placed to ensure proper visibility during the construction process. Furthermore, steel frame formwork is often designed with practical features, such as color-coded components or marking systems, which can assist workers in assembling and disassembling the formwork even in low-light conditions. Additionally, if necessary, reflective materials or paint can be applied to the steel frame formwork to increase visibility and safety on the construction site. While limited construction site lighting or visibility conditions may pose some challenges, proper planning and the use of additional lighting sources can ensure that steel frame formwork is used effectively and safely in such projects.

- Q:Can steel frame formwork be used for precast concrete cladding?

- Yes, steel frame formwork can be used for precast concrete cladding. Steel frame formwork provides a strong and sturdy structure, making it suitable for supporting the weight of precast concrete panels used for cladding. The steel frame formwork can be easily assembled and disassembled, allowing for efficient and cost-effective construction of the cladding system. Additionally, the steel frame formwork can be customized to accommodate different shapes and sizes of precast concrete panels, providing flexibility in design. Overall, steel frame formwork is a reliable and durable solution for constructing precast concrete cladding.

- Q:What is the difference between steel frame and steel frame?

- Steel structure refers to Taiwan tourism high-rise buildings above, or awning of this type is steel structure, steel frame is a large steel structure housing,

- Q:Are there any special considerations when using steel frame formwork in seismic zones?

- Yes, there are special considerations when using steel frame formwork in seismic zones. Steel frame formwork should be designed and constructed to withstand the potential ground shaking and lateral forces experienced in seismic zones. Additional reinforcement and bracing may be required to ensure the stability and integrity of the formwork during an earthquake. It is important to follow the local building codes and guidelines specific to seismic design to ensure the safety and performance of the steel frame formwork system in such zones.

- Q:How does steel frame formwork accommodate for expansion and contraction of concrete?

- Steel frame formwork accommodates for the expansion and contraction of concrete through its design and construction. Firstly, steel frame formwork allows for the placement of expansion joints in the concrete structure. These joints are created by leaving gaps in the formwork where the concrete can expand and contract without causing damage to the overall structure. Additionally, steel frame formwork is built with adjustable connections that allow for slight movement and shifting of the formwork as the concrete expands or contracts. These connections can be tightened or loosened as needed to accommodate for any changes in the dimensions of the concrete. Furthermore, steel itself has a relatively high coefficient of thermal expansion, which means it expands and contracts more compared to other materials. This property of steel helps to absorb some of the expansion and contraction stresses that the concrete may experience. The steel frame formwork acts as a buffer, absorbing and distributing these stresses to prevent cracking or distortion in the concrete. Overall, steel frame formwork is designed to provide flexibility and adaptability to the concrete structure, allowing it to expand and contract without compromising its integrity. This ensures the long-term durability and stability of the concrete construction.

- Q:How does steel frame formwork handle different types of formwork stripping equipment?

- Steel frame formwork is a versatile and durable system that can handle different types of formwork stripping equipment with ease. The steel frames, which are designed to provide stability and support, can accommodate various stripping tools such as mechanical or hydraulic systems. One of the advantages of steel frame formwork is its ability to withstand the high pressure and force exerted during the stripping process. This is crucial when different types of stripping equipment are used, as they require a strong and sturdy support system to ensure safe and efficient formwork removal. The steel frames are engineered to provide a stable and secure platform for the stripping equipment. They are designed with precision and accuracy to ensure proper alignment and compatibility with different types of stripping tools. This ensures that the stripping equipment can be securely attached to the steel frame formwork, allowing for effective and efficient formwork removal. Furthermore, steel frame formwork is highly adaptable, making it suitable for use with various types of formwork stripping equipment. Whether it is a mechanical stripping system that relies on mechanical force or a hydraulic system that utilizes hydraulic power, the steel frames can accommodate and work seamlessly with these different types of equipment. In conclusion, steel frame formwork is specifically designed to handle different types of formwork stripping equipment. Its strength, stability, and adaptability make it an ideal choice for construction projects that require efficient and safe formwork removal.

- Q:How does steel frame formwork handle the placement of embedded items and fixtures?

- Steel frame formwork is a versatile construction system that allows for easy handling and placement of embedded items and fixtures. Its modular design and adjustable features enable precise positioning of these elements within the concrete structure. The steel frames provide stability and support, ensuring that the embedded items and fixtures are securely held in place during the pouring and setting of the concrete. Additionally, the steel frame formwork allows for easy access and adjustments, making it convenient to install or modify embedded items and fixtures as per project requirements.

- Q:What are the different types of support brackets used with steel frame formwork?

- Some of the different types of support brackets used with steel frame formwork include adjustable brackets, fixed brackets, horizontal brackets, vertical brackets, and diagonal brackets. These brackets are designed to securely hold the formwork in place and provide stability during the concrete pouring process. Adjustable brackets allow for flexibility in adjusting the height and position of the formwork, while fixed brackets provide a more permanent and rigid support. Horizontal brackets are used to support the horizontal beams or panels of the formwork, while vertical brackets are used to support the vertical columns or walls. Diagonal brackets are used to provide additional stability and prevent any deflection or movement of the formwork structure.

- Q:Are steel frame formwork systems adjustable?

- Indeed, steel frame formwork systems possess the capability to be adjusted. These systems have been meticulously engineered to exhibit flexibility and adaptability to cater to diverse construction projects and demands. Typically crafted from top-notch steel, the frames ensure robustness and stability while allowing for alterations in both height and width. Moreover, certain steel frame formwork systems incorporate adjustable elements like telescopic beams, adjustable props, and brackets, which further augment their adaptability. This remarkable adjustability empowers contractors to effortlessly tailor the formwork to accommodate an array of concrete structures with varying shapes and sizes. All in all, steel frame formwork systems present a versatile and adjustable solution for construction endeavors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

various kinds of plastic formworks newly used

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords