Steel Frame Formworks for All Kinds of Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

-Light weight

-High strength

-High standardized system

-Easy connection with adjustable steel clamp

-Convenient and fast corner formwork

-Flexible to assemble and application

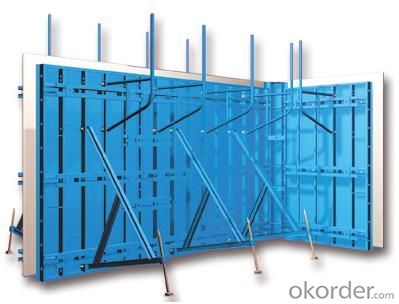

3. Steel Frame Formwork Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: European steel bed frame and rubber high density board that good

- Wei density board has moisture-proof fire protection function, and is a green product. Good visitors, nature, Sophia and other big brands have to use!

- Q: Is steel frame formwork suitable for all types of concrete structures?

- Steel frame formwork is not suitable for all types of concrete structures. It is commonly used in large-scale construction projects that require repetitive use. This formwork offers high strength and durability, enabling multiple reuses. Nevertheless, it may not be appropriate for small-scale projects or those with intricate designs that call for customized formwork. In such instances, alternative options like timber or aluminum formwork may prove more suitable. Furthermore, for projects with limited budgets or tight timelines, steel frame formwork may not be cost-effective. Thus, the suitability of steel frame formwork depends on the specific requirements and constraints of the concrete structure being built.

- Q: What are the different types of formwork systems that can be used in conjunction with steel frame formwork?

- There are several different types of formwork systems that can be used in conjunction with steel frame formwork. These include: 1. Timber formwork: Timber formwork is one of the most commonly used formwork systems. It involves using timber boards or plywood to create the formwork structure. Timber formwork is versatile, cost-effective, and easy to work with. It is suitable for a wide range of concrete structures, including walls, columns, beams, and slabs. 2. Aluminum formwork: Aluminum formwork is a lightweight and durable formwork system. It consists of aluminum panels that are connected together to create the formwork structure. Aluminum formwork is known for its high strength-to-weight ratio, which allows for faster construction and reduced labor costs. It is commonly used for repetitive structures like residential buildings and commercial complexes. 3. Plastic formwork: Plastic formwork is a relatively newer formwork system that is gaining popularity due to its versatility and ease of use. It is made of lightweight and durable plastic panels that can be easily assembled and disassembled. Plastic formwork is suitable for a wide range of concrete structures, including walls, columns, and slabs. It offers advantages such as lower labor costs, reduced formwork waste, and improved construction speed. 4. Fiberglass formwork: Fiberglass formwork is a lightweight and high-strength formwork system. It is made of fiberglass panels that are capable of withstanding high concrete pressures. Fiberglass formwork is suitable for a variety of concrete structures, including walls, columns, beams, and slabs. It offers advantages such as easy handling, reduced labor costs, and improved construction speed. 5. Modular formwork: Modular formwork refers to a system where standardized formwork components are used to create various formwork configurations. It can be used in conjunction with steel frame formwork by integrating the steel frames with the modular formwork components. Modular formwork is highly flexible and can be adjusted to suit different construction requirements. It is suitable for complex structures and can be easily reused, making it a cost-effective option. Overall, these different types of formwork systems offer a range of advantages, such as versatility, cost-effectiveness, ease of use, and increased construction speed. The choice of formwork system will depend on factors such as the construction project's requirements, budget, and timeline.

- Q: What are the main components of a steel frame formwork system?

- The steel frame formwork system is comprised of several key components. Firstly, the primary components are the steel frames which offer the necessary structural support and stability for the construction process. Constructed from high-quality steel, these frames are designed to withstand the weight and pressure of the poured concrete. Secondly, the steel frames are equipped with panels, typically made from durable materials such as plywood. These panels serve as the surface onto which the concrete is poured, providing the desired shape and finish to the structure. What's more, the panels can be easily removed and reused for multiple projects, making them a cost-effective choice. Next, adjustable props are utilized to support the steel frame formwork system and ensure its stability during the concrete pouring phase. These props can be adjusted to the desired height, offering flexibility when constructing structures of varying dimensions. Made from high-grade steel, these props are capable of withstanding heavy loads. In addition, tie rods are employed to hold the formwork system together and maintain its shape during the concrete pouring process. These rods are threaded and passed through holes in the panels, allowing for easy tightening or loosening as required. By providing extra strength and stability, the tie rods ensure that the formwork system maintains its shape until the concrete has fully cured. Lastly, wedges and clamps are used to securely fasten the panels to the steel frames, preventing any movement during the concrete pouring process. The wedges are inserted into slots on the frames and can be easily adjusted for a snug fit. Clamps are used to tightly secure the panels together, resulting in a solid and seamless formwork system. In summary, a steel frame formwork system consists of steel frames, panels, adjustable props, tie rods, wedges, and clamps. These components work in harmony to provide a robust and dependable solution for efficiently constructing various concrete structures.

- Q: What are the different types of accessories used with steel frame formwork?

- Steel frame formwork systems commonly utilize various accessories to enhance efficiency and effectiveness, as well as provide additional support and stability to the structure being formed. One frequently used accessory with steel frame formwork is the form tie. Form ties are employed to prevent the spreading apart of formwork panels under concrete pressure, effectively holding them together. Typically constructed from steel, form ties are available in different lengths to accommodate varying formwork heights. Another significant accessory is the formwork clamp, which securely fastens formwork panels to the steel frame, ensuring they remain in place during concrete pouring and curing. Formwork clamps come in different sizes and designs to suit various formwork configurations. Strong and durable formwork props or scaffolding are also necessary for supporting the weight of formwork panels and freshly poured concrete in steel formwork. These adjustable props provide stability to the formwork system and are typically made of steel, varying in size and load-bearing capacities. Additional accessories used in steel frame formwork include corner connectors for connecting formwork panels at 90-degree angles, and formwork release agents to prevent concrete from adhering to the formwork surface. Furthermore, accessories like formwork liners can be utilized to create different surface finishes on the concrete, while chamfer strips can produce beveled edges and smooth transitions between different formwork sections. In conclusion, the diverse range of accessories employed in steel frame formwork is aimed at delivering stability, support, and ease of use, ultimately ensuring the efficient and effective function of the formwork system during the concrete pouring process.

- Q: What are the transportation and storage requirements for steel frame formwork?

- The transportation and storage requirements for steel frame formwork are relatively straightforward. In terms of transportation, steel frame formwork is typically transported using trucks or trailers. Due to the weight of the steel frames, it is important to ensure that the vehicles used for transportation are capable of handling the load. The frames should be securely fastened to the vehicle to prevent any movement or damage during transit. As for storage, steel frame formwork should be stored in a dry and well-ventilated area to prevent rust or corrosion. Ideally, the frames should be stored indoors to protect them from the elements. If indoor storage is not possible, the frames should be covered with a waterproof tarp or sheeting to protect them from rain or snow. Additionally, it is important to stack the frames properly to avoid any deformation or damage. The frames should be stacked in a stable manner, with larger and heavier frames on the bottom and smaller frames on top. It is also recommended to place wooden spacers between the frames to prevent any direct contact and potential scratches. Regular maintenance and inspection of the steel frame formwork is also crucial to ensure its longevity and safety. This includes checking for any signs of damage, such as bent or cracked frames, and promptly addressing any issues that arise. Overall, proper transportation and storage of steel frame formwork is essential to protect the frames from damage and ensure their longevity, which in turn contributes to the efficiency and safety of construction projects.

- Q: Are there any specific requirements for the concrete mix used with steel frame formwork?

- Yes, there are specific requirements for the concrete mix used with steel frame formwork. The mix should usually have a higher strength and workability to ensure proper filling and support within the formwork. Additionally, it should have a low water-cement ratio to prevent excessive shrinkage and ensure durability. The concrete mix should also be compatible with the formwork system, considering factors like pouring and curing time. Overall, the specific requirements may vary depending on the project and design specifications.

- Q: What are the different types of support beams used with steel frame formwork?

- Construction projects commonly use several types of support beams in conjunction with steel frame formwork. These beams are crucial for providing stability and strength to the formwork system. Some of the support beams used with steel frame formwork include: 1. H-beams: These beams, shaped like the letter "H," are frequently used and have excellent load-bearing capacity due to their high-strength steel composition. 2. I-beams: Also known as universal beams, these beams have a cross-section shaped like the letter "I" and are ideal for bearing heavy loads. They are commonly employed in large construction projects that require high strength and stability. 3. Box beams: With a rectangular or square cross-section resembling a box, these beams possess a remarkable load-bearing capacity. They are typically utilized in projects where heavy loads need support. 4. Channel beams: Channel beams, or C-beams, have a cross-section shaped like the letter "C." They serve as secondary support beams in steel frame formwork, enhancing strength and stability. Channel beams are often used alongside other types of support beams. 5. Lattice beams: These lightweight and versatile support beams have a lattice-like structure. They are commonly employed in steel frame formwork to span long distances and offer a high level of flexibility. The selection of support beams for steel frame formwork depends on factors such as load requirements, project specifications, and budget constraints. Choosing the appropriate support beams is crucial to ensure the safety and stability of the formwork system throughout construction.

- Q: What are the main components of steel frame formwork?

- The primary elements of steel frame formwork are as follows: 1. Steel Frames: These serve as the fundamental components of steel frame formwork. They are crafted from top-notch steel and are engineered to provide stability and support while pouring concrete. The frames are typically modular and can be easily assembled and disassembled, making them incredibly versatile. 2. Plywood Panels: Plywood panels are utilized to construct the formwork surface onto which the concrete is poured. These panels are usually composed of high-quality plywood treated to be resistant to water and durable. The dimensions and thickness of the plywood panels may vary depending on the specific project requirements. 3. Tie Rods and Wing Nuts: Tie rods and wing nuts are employed to hold the steel frames together and ensure the stability of the formwork structure. The tie rods are threaded and can be adjusted to achieve the desired tension, while the wing nuts are used to secure the tie rods in place. 4. Adjustable Props: Adjustable props are employed to support the steel frame formwork and ensure that it maintains the correct position during the concrete pouring process. These props can be easily adjusted to the desired height and can withstand heavy loads. 5. Formwork Accessories: Various accessories such as clamps, connectors, and brackets are employed to connect and reinforce the steel frames. These accessories aid in ensuring the stability and integrity of the formwork structure. Overall, the primary components of steel frame formwork collaborate to create a robust and dependable system capable of supporting the weight of the concrete throughout the construction process. This type of formwork is widely utilized in the construction industry due to its durability, flexibility, and user-friendly nature.

- Q: How does steel frame formwork prevent concrete shrinkage or cracking?

- The robust and rigid structure of steel frame formwork effectively prevents concrete shrinkage or cracking. This is achieved by using steel frames as a support system during the curing process, holding the concrete in place and preventing any movement or shifting. As a result, the concrete dries evenly, reducing the risk of shrinkage or cracking. A key advantage of steel frame formwork is its ability to provide excellent reinforcement and stability to the concrete structure. The steel frames are designed with precise measurements and securely fixed, ensuring that the concrete retains its shape while it cures. This eliminates the potential for uneven drying or settlement, which can lead to shrinkage or cracking. Steel is an ideal material for formwork due to its high tensile strength and durability. The steel frames can withstand the pressure exerted by the wet concrete, preventing excessive expansion or contraction as it dries. This stability minimizes the development of internal stresses within the concrete, which are a common cause of shrinkage or cracking. Furthermore, steel frame formwork creates a smooth and seamless surface for the concrete, preventing the formation of voids or air pockets. This ensures that the concrete structure remains strong and reduces the likelihood of shrinkage or cracking. The tight fit between the steel frames ensures uniform distribution and compaction of the concrete, resulting in a stronger and more resilient finished product. In conclusion, steel frame formwork is crucial in preventing concrete shrinkage or cracking. Its stable and supportive structure, precise measurements, and ability to withstand pressure ensure that the concrete retains its shape and dries evenly. By eliminating uneven drying, settlement, and internal stresses, steel frame formwork helps create a high-quality, durable, and crack-free concrete structure.

Send your message to us

Steel Frame Formworks for All Kinds of Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches