Steel Fram Formworks Used for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork GK120 Description

There is a prizing part designed in the corner, which can help to position and remove formwork easily.The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

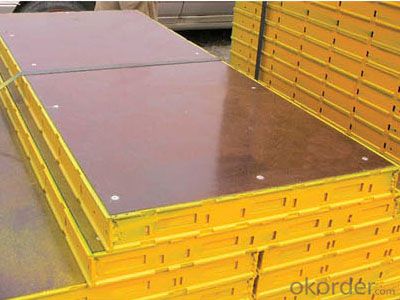

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120Specifications

Steel Frame Formwork GK120 is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the Steel Frame Formwork GK120 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Are there any safety precautions to consider when using steel frame formwork?

- Yes, there are several safety precautions to consider when using steel frame formwork. 1. Proper training: It is essential to ensure that all workers involved in using steel frame formwork are adequately trained on its installation, handling, and dismantling procedures. 2. Personal Protective Equipment (PPE): All workers must wear the appropriate PPE, including safety helmets, safety boots, gloves, and eye protection, to protect themselves from potential hazards. 3. Secure installation: The steel frame formwork should be securely installed and braced to prevent any collapse or movement during concrete pouring. 4. Regular inspection: Regular inspection of the steel frame formwork is crucial to identify any signs of damage or deterioration. Any damaged or worn-out parts should be replaced immediately. 5. Fall protection: Guardrails or safety nets should be installed to prevent falls from height. Additionally, workers should use harnesses and lanyards when working at elevated positions. 6. Load capacity: Ensure that the steel frame formwork is designed and rated to withstand the intended load. Overloading can lead to structural failure and accidents. 7. Safe material handling: When moving or lifting steel frame formwork, proper lifting techniques and equipment should be used to prevent strain or injury to workers. By following these safety precautions, the risks associated with using steel frame formwork can be minimized, ensuring a safe working environment for all involved.

- Q: Does steel frame formwork require any specific training for installation?

- Yes, steel frame formwork does require specific training for installation. Proper training is necessary to ensure that the formwork is correctly assembled and secured, as well as to ensure the safety of the workers involved. Training helps in understanding the technical aspects of steel frame formwork and enables workers to handle and install it efficiently.

- Q: Can steel frame formwork be used for curved or irregular shapes?

- Indeed, curved or irregular shapes can be constructed using steel frame formwork. Unlike conventional timber formwork, steel frame formwork offers greater flexibility and adaptability to accommodate diverse shapes and designs. The steel frames can be effortlessly bent or adjusted to achieve the desired curvature, facilitating the construction of curved or irregular structures. Moreover, the steel frames guarantee a robust and long-lasting support system, guaranteeing the stability and integrity of the formwork throughout the construction process. Consequently, steel frame formwork emerges as the optimal choice for projects involving curved or irregular shapes.

- Q: Can steel frame formwork be customized for specific project requirements?

- Yes, steel frame formwork can be customized for specific project requirements. The modular nature of steel frame formwork allows for flexibility in design and dimensions, making it adaptable to various construction projects. The formwork can be tailored to meet specific project requirements, such as unique shapes, sizes, and load-bearing capacities, ensuring efficient and precise construction processes.

- Q: How does steel frame formwork handle the placement of fire protection materials within the concrete structure?

- Steel frame formwork provides a highly efficient and effective solution for the placement of fire protection materials within concrete structures. The steel frame formwork system consists of modular panels and frames that are assembled to create a temporary structure for pouring and shaping the concrete. When it comes to fire protection, steel frame formwork allows for easy and precise installation of fire protection materials such as fireproofing coatings or fire-resistant boards. These materials can be applied directly to the surface of the steel frame formwork panels before the concrete is poured. The steel frame formwork system is designed to withstand the high temperatures that occur during a fire. It acts as a barrier, protecting the underlying concrete structure from the direct heat and flame exposure. Additionally, the steel frame formwork system provides structural integrity to the concrete, ensuring that it remains stable and intact even under fire conditions. Furthermore, steel frame formwork allows for flexibility in the placement of fire protection materials. Different areas of the concrete structure may require varying levels of fire resistance, and the modular nature of steel frame formwork allows for easy customization and adjustment to meet these specific requirements. In summary, steel frame formwork handles the placement of fire protection materials within the concrete structure by providing a stable and secure temporary structure for pouring and shaping the concrete. It allows for precise installation of fire protection materials, offers structural integrity and protection against high temperatures, and allows for flexibility in meeting specific fire resistance requirements.

- Q: European steel bed frame and rubber high density board that good

- Wei density board has moisture-proof fire protection function, and is a green product. Good visitors, nature, Sophia and other big brands have to use!

- Q: How does steel frame formwork handle different types of concrete finishing techniques?

- Steel frame formwork is a versatile and robust system that can effectively handle different types of concrete finishing techniques. The steel frame provides excellent stability and support to the formwork, allowing it to withstand the pressure and forces exerted during various finishing techniques. For smooth concrete finishes, steel frame formwork offers a level surface with minimal surface imperfections. The rigid structure of the steel frame ensures that the formwork remains in place during the pouring and curing process, resulting in a smooth and even finish. The formwork can be adjusted and aligned precisely to achieve the desired surface quality. In cases where textured or patterned finishes are required, steel frame formwork can accommodate these techniques as well. The formwork can be modified with additional elements such as inserts or molds to create unique patterns or textures on the concrete surface. The steel frame provides the necessary rigidity to ensure that the formwork retains its shape and the desired texture is achieved. Furthermore, steel frame formwork can also handle techniques such as exposed aggregate finishes. By incorporating removable panels or inserts, the formwork allows for the selective exposure of aggregates in the concrete surface. The steel frame provides the necessary strength to support the weight of the aggregates and prevents any deformation or displacement during the pouring process. Overall, steel frame formwork offers versatility and adaptability to various concrete finishing techniques. Its sturdy construction and ability to withstand different forces make it an ideal choice for achieving high-quality concrete finishes, regardless of the desired technique.

- Q: Can steel frame formwork be used in projects with special concrete requirements, such as high-strength or lightweight concrete?

- Yes, steel frame formwork can be used in projects with special concrete requirements, such as high-strength or lightweight concrete. Steel frame formwork is known for its strength and durability, making it suitable for handling the high loads and pressures associated with high-strength concrete. The rigid nature of steel formwork allows it to withstand the increased forces exerted by high-strength concrete during pouring and curing. Additionally, steel frame formwork can be easily customized and adjusted to accommodate the specific requirements of lightweight concrete. Lightweight concrete typically has lower density and requires special attention during pouring and curing to ensure uniformity and prevent segregation. Steel formwork can be designed with adjustable panels and supports to provide the necessary flexibility and stability required for pouring lightweight concrete. Furthermore, steel frame formwork offers numerous benefits for projects with special concrete requirements. It allows for precise shaping and finishing of concrete surfaces, ensuring accurate dimensions and smooth finishes. Steel formwork also provides excellent dimensional stability, minimizing the risk of deformation or settling during the curing process. Additionally, steel formwork can be reused multiple times, making it a cost-effective and sustainable solution for projects with special concrete requirements. In summary, steel frame formwork is a versatile solution that can be used in projects with special concrete requirements, such as high-strength or lightweight concrete. Its strength, durability, and customization options make it suitable for handling the unique challenges associated with these types of concrete.

- Q: What are the different types of formwork lifting devices used with steel frame formwork?

- There are various types of formwork lifting devices used with steel frame formwork, including manual hoists, electric hoists, crane systems, hydraulic jacks, and winches. These lifting devices are designed to safely lift and move the formwork components during construction, ensuring efficient and accurate installation of the steel frame formwork system.

- Q: What is the meaning of steel frame support structure?What is the support?

- Steel structure is a kind of economic and effective structure type for high-rise buildings, especially in seismic areas, and the supporting structure of steel frame is better than the frame structure,

Send your message to us

Steel Fram Formworks Used for Building Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches