different kinds of plastic formworks used in construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Plastic Formwork:

The biggest panel is 120x60cm, weight only 10.5kg, which can be lift and set up by only one person easily, need no crane on the site.

More and more people in the world would like to importPlasticformwork from China since recentyears. Plastic formwork is a new type construction material in the construction industry andpeople could buy good quality at a very good price from Chinese market. In this way, the distributors make more profit and the end users could save more cost. Before you decide to purchase this kind of plastic formwork, you need to know how plastic formwork sprung up and grasped the market.

2. The Advantages of Plastic Formwork:

1:easy set up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the

system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

2:modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls

and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls120x60 panel (act size 120x60cm) of multiple by 5cm. The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

3:strength

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

4:enviroment friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment.

5:consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

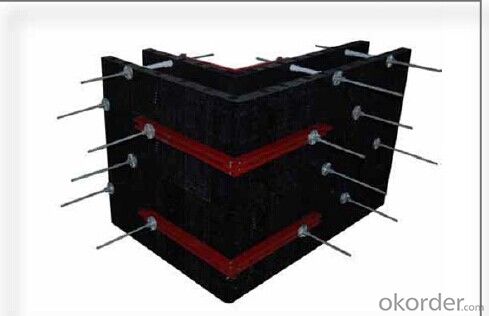

3. Images for Plastic Formwork:

4. FAQ of Plastic Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Plastic formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

- Q: What safety measures should be taken when using steel frame formwork?

- To ensure workers' well-being and prevent accidents or injuries, it is essential to implement various safety precautions when utilizing steel frame formwork. Here are some important measures to consider: 1. Personal Protective Equipment (PPE): All workers must wear suitable PPE, such as hard hats, safety goggles, gloves, and steel-toed boots, to protect against potential hazards like falling objects and sharp edges. 2. Training and Competency: Workers should receive adequate training and demonstrate competence in using the steel frame formwork system. This includes understanding assembly, dismantling, and usage procedures, as well as safe handling techniques, load limits, and proper tool and equipment usage. 3. Inspection and Maintenance: Regular inspections and maintenance of the steel frame formwork are crucial to identify any defects or damage that could compromise its structural integrity. This includes checking for cracks, rust, misalignments, loose or missing components, and signs of wear and tear. Prompt repairs or replacements should be carried out for damaged or faulty parts. 4. Proper Assembly and Dismantling: The steel frame formwork must be assembled and dismantled correctly, following the manufacturer's instructions and guidelines. Experienced and trained personnel should undertake these tasks to ensure stability and prevent accidents. Adequate bracing and support should be implemented during assembly to prevent collapse or movement. 5. Secure Fixing: The steel frame formwork should be securely fastened to the structure using appropriate clamps, bolts, or other fastening mechanisms. This will prevent any movement or displacement during concrete pouring or other construction activities. 6. Load Limits: Adhering to the load limits specified by the manufacturer is crucial. Overloading the steel frame formwork can result in structural failures or collapse. Therefore, the weight of the concrete, construction materials, and workers should be carefully calculated and monitored to avoid exceeding the maximum load capacity. 7. Fall Protection: Proper fall protection systems, such as guardrails, safety nets, or personal fall arrest systems, should be in place to prevent falls from heights. This is particularly important when workers are operating on elevated platforms or platforms with openings. 8. Communication and Coordination: Clear communication and coordination among workers are essential to creating a safe working environment. This includes providing instructions, warnings, and signals to prevent accidents and ensure a smooth workflow. By implementing these safety measures, the risk of accidents, injuries, and structural failures can be significantly reduced when using steel frame formwork. Prioritizing safety and providing ongoing training and supervision to all personnel involved in the construction process are crucial aspects to consider.

- Q: Does steel frame formwork require any specific surface preparation?

- Yes, steel frame formwork does require specific surface preparation before it can be used. The surface of the steel frame needs to be cleaned and free from any dirt, rust, or other contaminants. This can be done by using a wire brush or abrasive material to remove any loose or flaking paint, rust, or debris. After cleaning, the surface should be treated with a primer or anti-corrosion coating to protect the steel from further rusting. This will ensure that the steel frame formwork is in good condition and will provide a strong and stable structure for concrete pouring.

- Q: Can steel frame formwork be used for tunnel and underground construction?

- Yes, steel frame formwork can be used for tunnel and underground construction. Steel frame formwork is a versatile and robust construction system that can be easily adapted to various project requirements, including tunnel and underground construction. One of the key advantages of steel frame formwork is its durability and strength. Steel is a strong and rigid material that can withstand the high pressures and loads associated with tunnel and underground construction. It provides a stable and secure framework for pouring concrete, ensuring the structural integrity of the tunnel or underground structure. Steel frame formwork also offers flexibility in terms of design and construction. It can be easily customized and adjusted to fit the specific dimensions and shape of the tunnel or underground structure. This allows for efficient use of space and ensures that the formwork provides a precise and accurate mold for the concrete. Furthermore, steel frame formwork is highly reusable, making it a cost-effective solution for tunnel and underground construction projects. The frames can be easily dismantled and reassembled for use in subsequent projects, reducing the need for new formwork materials and minimizing waste. In conclusion, steel frame formwork is a suitable and effective choice for tunnel and underground construction. Its durability, strength, flexibility, and reusability make it an ideal construction system for creating the necessary molds and structures within tunnels and underground spaces.

- Q: What is the expected lifespan of steel frame formwork?

- The expected lifespan of steel frame formwork can vary depending on various factors such as the quality of the steel, maintenance practices, and usage conditions. However, with proper care and maintenance, steel frame formwork can last for many years, typically ranging from 10 to 20 years or even longer.

- Q: What are the common maintenance practices for steel frame formwork systems?

- To maintain steel frame formwork systems, it is important to regularly clean and inspect them, lubricate their moving parts, and repair or replace any damaged components. Cleaning is a crucial maintenance practice that involves removing any debris, concrete residue, or other materials that may have accumulated on the frames and panels. By regularly cleaning the formwork system, you can prevent corrosion and ensure its overall good condition. Inspection is another essential maintenance practice. It involves thoroughly examining the formwork system for any signs of damage or wear. This includes inspecting the frame, panels, connecting hardware, and other components for cracks, dents, or loose parts. It is important to conduct inspections before and after each use, as well as periodically during long projects. If any issues are detected during the inspection, they should be promptly addressed to prevent further damage. Lubrication is necessary for the smooth operation of the moving parts in a steel frame formwork system. This includes applying lubrication to hinges, locks, and other mechanisms to ensure their proper functioning. By lubricating these parts, you can reduce friction and wear, which in turn can extend the lifespan of the formwork system and enhance its performance. Repairing or replacing damaged components is crucial for maintaining the integrity of the steel frame formwork system. Any components that are cracked, bent, or otherwise damaged should be repaired or replaced as soon as possible. This may involve replacing worn-out panels, repairing damaged frames, or replacing faulty hardware. Regular inspections and prompt repair or replacement of damaged components can prevent accidents and help ensure that the formwork system remains safe and reliable. To summarize, common maintenance practices for steel frame formwork systems include regular cleaning and inspection, lubrication of moving parts, and repair or replacement of damaged components. By following these practices, you can ensure the longevity and proper functioning of the formwork system, promoting safety and efficiency on construction sites.

- Q: Can steel frame formwork be used for both precast and cast-in-place concrete walls?

- Steel frame formwork is a highly versatile and durable system that can be utilized for both precast and cast-in-place concrete walls. Its adaptability and ease of assembly and disassembly make it suitable for a wide range of construction processes. When it comes to precast concrete walls, the steel frame formwork is employed to establish the mold or form for the concrete panel. Following this, the concrete panel is cast and cured off-site before being transported and installed. As for cast-in-place concrete walls, the steel frame formwork is used on-site to create the formwork for the concrete wall, which is then poured and cured in place. The remarkable flexibility of steel frame formwork enables its application in both precast and cast-in-place scenarios, delivering efficient and dependable outcomes to cater to diverse construction requirements.

- Q: How does steel frame formwork contribute to better dimensional accuracy in concrete structures?

- Steel frame formwork is a construction technique that utilizes steel frames to hold the formwork panels in place during the concrete pouring process. This method offers several advantages that directly contribute to better dimensional accuracy in concrete structures. Firstly, steel frame formwork provides a rigid and stable framework that ensures the formwork panels remain in position without any movement or deformation. This stability prevents any shifting or misalignment of the formwork during the pouring and curing of the concrete. As a result, the concrete structure can be constructed with precise dimensions and accurate alignment. Additionally, steel frame formwork allows for easy adjustment and customization. The steel frames can be easily modified or resized to accommodate various shapes, sizes, and complexities of concrete structures. This adaptability ensures that the formwork perfectly fits the desired dimensions and contours of the structure, resulting in enhanced dimensional accuracy. Furthermore, steel frame formwork offers excellent strength and durability. The use of steel frames provides a robust support system that can withstand the weight and pressure exerted by the poured concrete. This strength prevents any deformation or bending of the formwork, ensuring that the concrete structure remains true to its intended dimensions. Moreover, steel frame formwork facilitates efficient and consistent concrete pouring. The formwork panels are designed to have smooth surfaces, which allow for easy and uniform distribution of the concrete. This controlled pouring process ensures that the concrete is evenly distributed, minimizing any inconsistencies or irregularities in the structure's dimensions. Lastly, steel frame formwork is reusable and cost-effective. The steel frames can be dismantled and reused for multiple construction projects, reducing the overall construction costs. The ability to reuse the formwork also ensures that the dimensions and accuracy achieved in previous projects can be replicated, maintaining a high level of dimensional accuracy across different concrete structures. In conclusion, steel frame formwork significantly contributes to better dimensional accuracy in concrete structures. Its stability, adjustability, strength, efficiency, and reusability all work together to ensure that the concrete structure is constructed with precise dimensions and alignment, resulting in a high-quality and accurately built final product.

- Q: What are the different methods of bracing steel frame formwork?

- Construction projects commonly utilize various methods to brace steel frame formwork. These techniques encompass: 1. Diagonal bracing: To reinforce steel frame formwork, diagonal bracing is frequently employed. It entails the installation of diagonal members at different angles to enhance stability and withstand lateral forces. These members can be constructed from steel, timber, or aluminum. 2. Cross bracing: Stability and resistance against horizontal forces are achieved through cross bracing. This method involves the installation of intersecting horizontal and vertical members forming an X shape. Typically, cross braces are composed of steel or other high load-bearing materials. 3. Tension bracing: In structures with significant tension forces, tension bracing is commonly utilized. This technique involves the installation of cables or rods under tension to provide stability and resist lateral forces. High-strength steel or materials with high tensile strength are often used for tension braces. 4. Shear bracing: Shear bracing is employed to counteract shear forces. Members capable of resisting shear forces are typically installed diagonally or horizontally and are constructed from steel or other shear-resistant materials. 5. Moment bracing: Moment bracing ensures stability and resistance against moment forces. These braces are typically placed at the corners or edges of the steel frame formwork to withstand bending or twisting forces. Usually, moment braces are made from steel or other structurally robust materials. In conclusion, the selection of a bracing method relies on specific project requirements, including structure height and size, expected loads and forces, and material choices. Consulting with structural engineers and adhering to building codes and regulations is vital to ensure the safety and stability of the steel frame formwork during the selection and installation of bracing methods.

- Q: What are the different types of support beams used with steel frame formwork?

- There are several types of support beams commonly used with steel frame formwork. These include H-beams, I-beams, channel beams, and box beams. H-beams are often used for heavy-duty applications due to their high load-bearing capacity. I-beams are suitable for long-span structures and offer excellent strength-to-weight ratio. Channel beams are often used for lighter loads and offer versatility in terms of connection options. Box beams are hollow and provide high stiffness and resistance to bending. Ultimately, the type of support beam chosen depends on the specific requirements of the construction project.

- Q: How does steel frame formwork handle different types of formwork leveling systems?

- Steel frame formwork is designed to accommodate various types of formwork leveling systems. These systems, such as adjustable props or scaffolding, are used to ensure the formwork is leveled and properly supported. The steel frame formwork provides a stable and robust structure that can easily integrate with these leveling systems, allowing for precise and accurate alignment of the formwork components. This enables efficient and effective construction processes, ensuring the desired quality and structural integrity of the finished project.

Send your message to us

different kinds of plastic formworks used in construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches