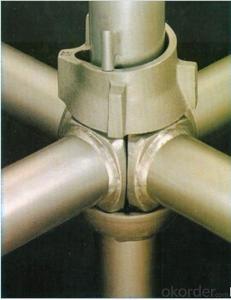

Scaffolding Cover Formwork Scaffolding Clamp Price New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Formwork Concrete Formwork Platform Outrigger for Scaffolding High Quality

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

- Q: What is the cost difference between steel frame formwork and other types of formwork?

- The cost difference between steel frame formwork and other types of formwork can vary depending on several factors. Steel frame formwork is generally considered to be more expensive than other types of formwork such as timber or aluminum. This is primarily due to the higher cost of steel as a material compared to timber or aluminum. Additionally, steel frame formwork requires skilled labor and specialized equipment for installation, which can further contribute to its higher cost. However, it is important to consider the long-term benefits and cost-effectiveness of steel frame formwork. Steel frame formwork is known for its durability and reusability, which can offset its initial higher cost. Unlike timber formwork, steel frame formwork can withstand multiple uses, resulting in reduced overall costs over time. Moreover, steel frame formwork offers better structural stability and accuracy, resulting in fewer material wastages and increased construction efficiency. Furthermore, the cost difference between steel frame formwork and other types of formwork can also be influenced by the specific project requirements and scale. For large-scale projects with complex designs and high load-bearing requirements, steel frame formwork may be more cost-effective in the long run due to its durability and ability to handle heavy loads. In summary, while steel frame formwork may initially have a higher cost compared to other types of formwork, its long-term benefits such as durability, reusability, and structural stability can make it a more cost-effective choice for certain construction projects.

- Q: How does steel frame formwork handle the placement of temporary supports and shoring systems within the concrete structure?

- Steel frame formwork is a highly efficient and versatile system that allows for easy placement of temporary supports and shoring systems within the concrete structure. The steel frame formwork consists of modular panels that are assembled and locked together to create a sturdy and rigid framework. This framework not only provides the necessary support for the concrete during the pouring and curing process but also allows for the integration of temporary supports and shoring systems. Temporary supports are used to provide additional support to the formwork and the concrete structure during construction. These supports are typically made of steel or timber and are strategically placed to bear the weight of the concrete and prevent any sagging or deformation. The steel frame formwork provides multiple attachment points and brackets that allow for the easy integration and adjustment of these temporary supports. The modular nature of the formwork allows for flexibility in positioning the supports, ensuring proper distribution of loads and maintaining the integrity of the structure. Shoring systems, on the other hand, are used to provide vertical support to the concrete structure, especially in areas where there are large spans or heavy loads. Steel frame formwork offers various options for incorporating shoring systems, including adjustable props, hydraulic jacks, and telescopic beams. These systems can be easily installed and adjusted within the formwork to provide the necessary support and ensure the stability of the structure. In addition to providing a platform for the placement of temporary supports and shoring systems, steel frame formwork also offers numerous advantages in terms of speed, efficiency, and cost-effectiveness. The lightweight yet robust nature of the steel frame formwork allows for quick assembly and dismantling, reducing construction time and labor costs. Furthermore, the versatility of the system allows for reuse on multiple projects, resulting in significant cost savings over time. Overall, steel frame formwork provides a reliable and efficient solution for handling the placement of temporary supports and shoring systems within the concrete structure. Its modular design, flexibility, and ease of use make it an ideal choice for various construction projects, ensuring the safety and stability of the concrete structure during the construction process.

- Q: What are the different types of climbing formwork systems used with steel frame formwork?

- There are several types of climbing formwork systems used with steel frame formwork, including crane-lifted climbing formwork, hydraulic climbing formwork, and self-climbing formwork. These systems allow for the vertical progression of the formwork, enabling construction workers to efficiently construct tall structures such as high-rise buildings and bridges.

- Q: How does steel frame formwork affect the overall quality of the concrete structure?

- Steel frame formwork can significantly improve the overall quality of a concrete structure. Its robustness and stability provide excellent support to the concrete during the pouring and curing process, ensuring proper alignment and preventing any deformations. This formwork system also allows for precise shaping of the concrete, leading to accurate dimensions and smooth surfaces. Additionally, steel frame formwork enables faster construction and easier maintenance, contributing to a more efficient and durable concrete structure.

- Q: Are there any limitations to the number of reuses for steel frame formwork panels?

- Yes, there are limitations to the number of reuses for steel frame formwork panels. While steel is a durable and strong material, it is not invincible and can deteriorate over time with repeated use. Some of the limitations include: 1. Fatigue: With each use, the steel frame formwork panels are subjected to various loads and stresses. Over time, this can lead to fatigue, causing the steel to weaken and eventually fail. 2. Corrosion: Steel is susceptible to corrosion when exposed to moisture, chemicals, or environmental conditions. Corrosion can weaken the structural integrity of the panels, making them less suitable for reuse. 3. Wear and tear: The repeated assembly, disassembly, and transportation of steel formwork panels can cause wear and tear. This can lead to deformation, cracks, or other damage, making the panels less effective and safe for reuse. 4. Surface imperfections: During the concrete pouring process, the formwork panels can experience surface imperfections such as scratches, dents, or concrete residue buildup. These imperfections can affect the quality of subsequent concrete pours and may require repair or replacement of the panels. 5. Changes in construction requirements: Over time, there may be changes in construction methods, designs, or building codes that render older steel formwork panels obsolete. This can limit their reuse as they may not meet the updated requirements. To ensure the safe and effective reuse of steel frame formwork panels, regular inspections, maintenance, and repairs are necessary. It is also important to follow manufacturer guidelines and industry best practices to determine the suitable number of reuses for each panel, taking into account its condition, history of use, and the specific construction project requirements.

- Q: How does steel frame formwork help in reducing construction errors?

- Steel frame formwork helps in reducing construction errors by providing a strong and stable structure for concrete pouring. It ensures accurate alignment and measurement, preventing deviations and inconsistencies in the final construction. With its robustness and precision, steel frame formwork minimizes the risk of mistakes such as uneven walls or floors, misplaced openings, or structural deficiencies, resulting in a more efficient and error-free construction process.

- Q: What are the different components of steel frame formwork?

- The steel frame formwork typically consists of various components: 1. Panels serve as the primary element of the system, made from steel or aluminum. They are designed to be lightweight yet sturdy, coming in different sizes, shapes, and thicknesses based on the required strength and load-bearing capacity. 2. To ensure a tight and secure formwork system, connecting pins made of steel are used to join the panels together. These pins are inserted through pre-drilled holes in the panels, providing stability and preventing any movement or displacement during concrete pouring. 3. Wedges, usually made of steel or plastic, are used in conjunction with the connecting pins to further secure the formwork system. They are inserted between the panels and pins, creating a tight fit and preventing any gaps or spaces that could lead to leakage or uneven concrete placement. 4. Props are vertical support devices made of steel, providing additional strength and stability to the formwork system. They can be adjusted in height, allowing flexibility in formwork installation. Props play a crucial role in supporting the weight of the concrete and formwork, ensuring a safe and reliable construction process. 5. Braces, made of steel, are horizontal or diagonal supports used to reinforce the formwork system and prevent any buckling or bending of the panels. They are installed at regular intervals, providing additional stability and rigidity to the formwork structure. 6. Various accessories, including clamps, ties, and brackets, may also be included in the steel frame formwork system. These accessories secure the formwork system to the existing structure, ensure accurate panel alignment, and provide additional reinforcement where necessary. Collectively, these components form a robust and reliable system for concrete construction. The combination of panels, connecting pins, wedges, props, braces, and accessories guarantees a strong and stable formwork structure capable of withstanding the pressures and forces exerted during the concrete pouring process.

- Q: Can steel frame formwork be used for the construction of sports facilities?

- Yes, steel frame formwork can be used for the construction of sports facilities. Steel frame formwork provides high strength and durability, making it suitable for the construction of large and complex structures like stadiums, indoor arenas, and sports facilities. It offers flexibility in design, allowing for customization according to the specific requirements of the sports facility. Additionally, steel frame formwork can be easily assembled and disassembled, making it efficient for construction projects with tight timelines.

- Q: PKPM steel frame design inside the full design of the nodes inside the connection parameters are determined by the design institute to teach me

- Design of node connection parameters according to the actual situation, you project such as beam column connection, the connection plate thickness, column, beam connection, bolt size and form... And so on, according to the specific requirements of your project

- Q: Can steel frame formwork be used in underground construction projects?

- Yes, steel frame formwork can be used in underground construction projects. Steel frame formwork is a versatile and durable system that is commonly used in various construction applications, including underground projects. Its strength and rigidity make it suitable for withstanding the pressures and forces associated with underground construction. Steel frame formwork is typically made of high-grade steel, which provides excellent structural integrity and resistance to deformation. This makes it ideal for use in underground projects, where there may be increased levels of pressure from the soil and surrounding environment. Moreover, steel frame formwork offers flexibility in design and can be easily customized to meet the specific requirements of underground construction projects. It allows for the creation of complex shapes and structures, which are often necessary in underground constructions such as tunnels, subway systems, and basements. Additionally, steel frame formwork is known for its reusability, which can significantly reduce costs and environmental impact in underground construction. The formwork can be easily dismantled, moved, and reassembled in different locations, making it a cost-effective choice for projects that involve multiple construction phases. In summary, steel frame formwork is a suitable choice for underground construction projects due to its strength, durability, flexibility, and reusability. It offers the necessary structural support and adaptability required for the challenges associated with underground construction, making it a preferred choice for many engineers and contractors.

Send your message to us

Scaffolding Cover Formwork Scaffolding Clamp Price New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches