Steel Prop & Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

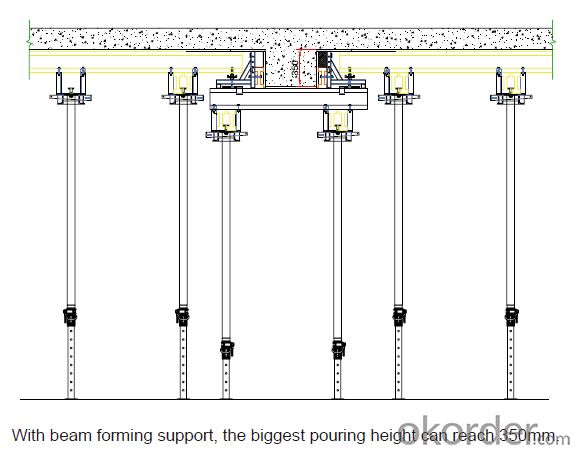

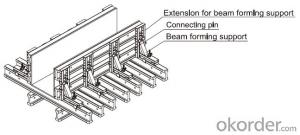

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used in commercial building construction?

- Yes, steel props can be used in commercial building construction. Steel props, also known as adjustable steel props or telescopic props, are commonly used for temporary support during construction work. They provide stability and strength to the structure, ensuring the safety of workers and the integrity of the building. Due to their adjustable nature, steel props can be easily customized to fit different heights and support various building components. Additionally, their robust construction allows them to withstand heavy loads and pressures, making them suitable for commercial building projects.

- Q: What are the different types of steel prop accessories available?

- Some different types of steel prop accessories available include adjustable heads, base plates, bracing systems, prop sleeves, prop pins, and prop nuts. These accessories are used to enhance the stability, strength, and versatility of steel props in construction and formwork applications.

- Q: What are the potential risks and hazards associated with steel props?

- Steel props, also referred to as adjustable steel props or acrow props, find frequent use in construction and temporary support systems. While they offer several advantages, their use comes with potential risks and hazards. 1. Structural Failure: One of the most significant hazards involves the possibility of structural failure. Steel props can collapse or buckle if subjected to excessive loads or if installed incorrectly. Such incidents can result in severe injuries or even fatalities for workers and bystanders. 2. Overloading: Another risk arises from overloading the props beyond their weight-bearing capacity. Should the load exceed the props' specifications, they may deform or fail, leading to accidents or damage to nearby structures. 3. Improper Placement: Inadequate placement of steel props can pose hazards. If not correctly and securely positioned, they may slip or fall, thereby causing instability in the supported structure and potential risks for workers. 4. Insufficient Bracing: Insufficient bracing can also give rise to risks. Steel props require proper bracing to ensure lateral stability and prevent buckling or collapse. Failure to provide adequate bracing may result in accidents or damage to the supported structure. 5. Inadequate Maintenance: Failure to conduct regular inspections and maintenance can lead to risks. Over time, steel props may develop rust, corrosion, or other structural weaknesses that compromise their integrity. Neglecting to promptly identify and address these issues can increase the likelihood of accidents. 6. Poor Training and Supervision: Insufficient training and supervision of workers using steel props can contribute to hazards. Without adequate knowledge of usage guidelines, workers may fail to assess loads properly, install the props correctly, or ensure appropriate bracing, thereby increasing the risks associated with their use. 7. Falling Objects: When steel props support scaffolding or other temporary structures, falling objects become a hazard. Insecurely fastened or stored materials or tools may fall from the elevated platform, potentially causing injuries to workers or bystanders. To mitigate these risks and hazards, it is crucial to comply with safety regulations and standards, provide comprehensive training to workers, regularly inspect and maintain steel props, and ensure proper installation and bracing. Additionally, employing suitable personal protective equipment and implementing safety measures like barricades or warning signs can help minimize the potential dangers associated with steel props.

- Q: I would like to ask the steel support line load is 420kn/m (design value), 20 meters deep foundation pit, steel support diameter of 609, wall thickness of 16mm

- So, what you said is the foundation pit excavation, pipe ends supporting, then why have load and steel 420kN/m?Do you want to build a house above the shop?

- Q: What are the common accessories used with steel props?

- There are several common accessories that are used with steel props to enhance their functionality and ensure safety on construction sites. These accessories include: 1. Prop heads: These are used to provide additional support to the top of the props. They are typically made from steel or cast iron and are designed to distribute the load evenly across the prop, preventing it from sinking into the ground or damaging the structure it is supporting. 2. Prop plates: These are flat steel plates that are placed under the base of the props to distribute the load and prevent them from sinking into the ground. Prop plates also provide stability and prevent the props from tipping over. 3. Prop pins: These are long steel pins used to secure the props in their desired height position. They are inserted through the holes in the props and prop heads and are typically secured with a locking mechanism to ensure they do not come loose during use. 4. Prop nuts: These are used to secure the prop pins in place. They are tightened onto the threaded end of the pin to prevent it from moving and provide additional stability to the props. 5. Adjustable prop wrench: This is a specialized tool used to adjust the height of the props. It allows construction workers to easily extend or retract the props to the desired height, providing flexibility and adaptability to different construction requirements. 6. Base plates: These are large steel plates that are used as a stable foundation for the props. They are placed under the prop plates to distribute the load and prevent sinking or tipping. 7. Scaffolding tubes: In some cases, steel props are used in conjunction with scaffolding systems. Scaffolding tubes are used to connect the props horizontally, creating a sturdy framework for workers to move and work on various levels of a construction site. These accessories are essential for ensuring the stability, safety, and adaptability of steel props on construction sites. They not only enhance the functionality of the props but also contribute to the overall safety of the workers and the structural integrity of the construction project.

- Q: Do steel props require any special tools for installation and adjustment?

- Yes, steel props typically require special tools such as spanners or wrenches for installation and adjustment. These tools are used to tighten and loosen the adjustable components of the props, allowing for proper installation and adjustment according to the required height and load-bearing capacity.

- Q: What are the different components of a steel prop?

- A steel prop, also called a steel shore or steel prop jack, comprises several components. These include a threaded steel tube, a base plate, a top plate, and a locking mechanism. The main part of the prop is the threaded steel tube, which is used to adjust its height. It is constructed from high-strength steel to ensure adequate support and stability. The tube features a threaded section that allows for effortless height adjustment. Attached to the bottom of the prop is the base plate, a flat metal plate. This plate serves as a stable foundation, preventing the prop from sinking into the ground or damaging the underlying surface. It also aids in distributing the load evenly. Some base plates are equipped with holes or slots for anchoring or securing the prop to the ground or other structures. On the top of the prop is the top plate, another metal plate. This plate provides support for the load carried by the prop. It is typically larger than the base plate to maximize contact with the supported structure, ensuring efficient load distribution. The locking mechanism is a crucial element of the steel prop, ensuring its secure height adjustment. It typically consists of a pin or collar that can be tightened to lock the prop in place and prevent accidental slipping or collapsing under load. This mechanism guarantees the stability and safety of the prop during construction or temporary support applications. In summary, these components collaborate to create a robust and adjustable support system for various construction or temporary shoring requirements. They are designed to be durable, reliable, and user-friendly, making steel props indispensable tools in the construction industry.

- Q: What are the common lengths available for steel props?

- The available lengths of steel props differ from manufacturer to manufacturer and depend on the specific requirements of the construction project. Nevertheless, steel props generally come in lengths ranging from 1.8 meters (6 feet) to 5.4 meters (18 feet). These lengths are commonly employed in diverse applications, including supporting formwork, shoring systems, and providing temporary structural support during construction or renovation projects. It should be emphasized that tailor-made lengths can also be produced to meet the specific needs of a project.

- Q: How do you calculate the number of steel props needed for a project?

- To calculate the number of steel props needed for a project, you would typically consider factors such as the load-bearing capacity of each prop, the dimensions and weight of the structure being supported, and the spacing required between the props. By analyzing these parameters, you can determine the appropriate number of steel props needed to ensure adequate support and safety for the project.

- Q: Can steel props be used for supporting temporary greenhouses or agricultural structures?

- Yes, steel props can be used for supporting temporary greenhouses or agricultural structures. Steel props are strong, durable, and have high load-bearing capacity, which makes them suitable for providing structural support to temporary greenhouses or agricultural structures. They can be easily adjusted to the required height and provide stability to the structure. Moreover, steel props can withstand various weather conditions and are resistant to corrosion, ensuring the longevity of the support system. Overall, steel props are a reliable and cost-effective option for supporting temporary greenhouses or agricultural structures.

Send your message to us

Steel Prop & Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords