Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

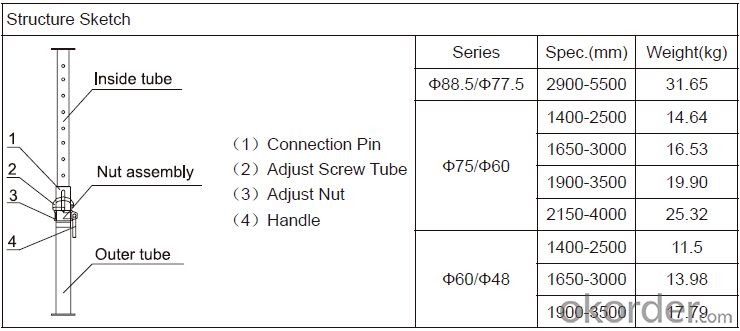

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

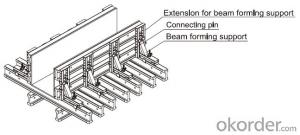

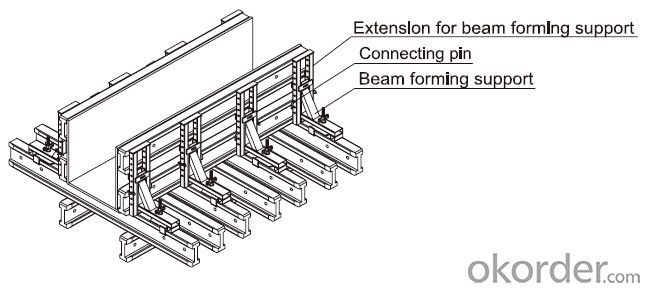

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Are steel props adjustable under load?

- Adjusting steel props while under load is not recommended. Steel props, also known as adjustable steel columns or acrow props, are specifically designed to support vertical loads during construction or renovation work. They are typically utilized to provide temporary support to beams, floors, or walls. Steel props are comprised of two primary components: an inner tube and an outer tube. The desired height can be achieved by adjusting the inner tube using a threaded mechanism, such as a screw or pin system. However, this adjustment should only be performed when the prop is not under load. It is strongly advised against adjusting the height of the prop once it is loaded and supporting a load. Doing so can compromise the stability and safety of the structure. Unpredictable movements or collapses may occur, potentially resulting in damage to the surrounding area or injury to workers. To ensure the safety and stability of the structure, it is crucial to determine the appropriate height and position of the steel props before loading them. This process should be carried out in accordance with the manufacturer's guidelines and with the assistance of a qualified engineer or construction professional.

- Q: How do you prevent theft of steel props from construction sites?

- There are several measures that can be taken to prevent theft of steel props from construction sites. Firstly, implementing a secure fencing system around the site with access control mechanisms can significantly deter thieves. Additionally, installing security cameras and proper lighting can help identify any suspicious activities. Storing steel props in a locked and monitored storage area when not in use can also minimize the risk of theft. Conducting regular inventory checks and keeping records of the props can aid in identifying any missing items quickly. Lastly, involving local authorities and collaborating with neighboring businesses or residents to report any suspicious activities can further enhance security and deter theft.

- Q: What are the different materials used for steel props?

- Steel props, also known as adjustable steel props or steel scaffolding props, are essential tools used in construction to support temporary structures such as walls, beams, and slabs. These props are made from various materials to ensure strength, stability, and durability. 1. Steel: The primary material used for steel props is steel itself. It is known for its high tensile strength, which makes it capable of withstanding heavy loads. Steel props are commonly made from high-quality steel, ensuring the necessary resistance against compression and bending forces. 2. Galvanized Steel: Some steel props are coated with zinc through a process called galvanization. Galvanized steel props offer enhanced corrosion resistance and increased longevity. This type of coating helps protect the props from rust and deterioration, making them suitable for use in both indoor and outdoor construction projects. 3. Aluminum: Although less common than steel, aluminum is also used to make steel props. Aluminum props are lightweight and easy to handle, making them ideal for situations where portability is essential. They are often used in smaller-scale construction projects or areas where weight restrictions are a concern. 4. Composite Materials: In recent years, composite materials have gained popularity in the construction industry. These materials, typically made by combining plastic or fiberglass with other elements, offer excellent strength-to-weight ratios and corrosion resistance. Composite steel props are lightweight, durable, and resistant to weathering, making them suitable for various construction applications. The choice of material for steel props depends on factors such as the load-bearing requirements, environmental conditions, and budget constraints. Steel props made from high-quality steel or galvanized steel are widely used due to their excellent strength and durability. Aluminum props are preferred in situations where weight is a crucial consideration. Additionally, composite materials are gaining traction as an alternative to traditional steel props, offering a combination of strength, lightweight, and resistance to corrosion.

- Q: How are steel props transported to the construction site?

- Depending on their size and quantity, steel props are transported to the construction site using various methods. One way is through the utilization of flatbed trucks or trailers, where the props are firmly loaded onto the truck bed and secured with straps or chains to maintain stability while in transit. Alternatively, steel props may be transported in shipping containers for long-distance trips. In this method, the props are loaded and secured inside the container and then transported by road, rail, or sea. This approach safeguards the props from external factors and simplifies handling and loading/unloading at the construction site. For smaller quantities or shorter distances, smaller vehicles like pickup trucks or vans may be employed to transport the steel props. This is commonly done when the construction site is nearby or when urgent delivery is required. Irrespective of the transportation method chosen, it is crucial to ensure that the steel props are loaded, secured, and transported in a safe and lawful manner. Following transportation regulations and guidelines is essential in order to prevent accidents or damage during transit, guaranteeing that the steel props arrive at the construction site in excellent condition and ready for use.

- Q: What are the advantages of using steel props over traditional wooden supports?

- There are several advantages to using steel props over traditional wooden supports in construction projects. Firstly, steel props offer a higher load-bearing capacity compared to wooden supports. Steel is a stronger material, allowing it to support heavier loads, making it ideal for larger and more complex construction projects. This increased load-bearing capacity ensures a higher level of safety and stability on the construction site. Secondly, steel props are more durable and long-lasting than wooden supports. Wood is prone to wear and tear, rotting, and warping over time. In contrast, steel is highly resistant to these issues, making it more reliable and cost-effective in the long run. Steel props can withstand harsh weather conditions, moisture, and pests, which can significantly extend their lifespan. Moreover, steel props offer greater adjustability and versatility. They are usually telescopic or adjustable in nature, allowing for easy height adjustments to accommodate different construction requirements. This adjustability feature makes steel props suitable for a wide range of applications such as supporting beams, columns, and ceilings. On the other hand, wooden supports often require cutting or trimming to achieve the desired height, which can be time-consuming and less precise. Another advantage of steel props is their ease of installation. Steel props are typically pre-fabricated and ready to use, requiring minimal assembly on-site. This saves valuable time and labor costs during the construction process. Additionally, the lightweight nature of steel props makes them easier to transport and handle, reducing the risk of accidents and injuries. Lastly, steel props are more environmentally friendly compared to wooden supports. Steel is a recyclable material, which means that it can be reused or repurposed at the end of its life cycle. In contrast, wooden supports often end up as waste, contributing to deforestation and environmental degradation. In summary, the advantages of using steel props over traditional wooden supports are higher load-bearing capacity, durability, adjustability, ease of installation, and environmental sustainability. These benefits make steel props a preferred choice in modern construction projects, ensuring safety, efficiency, and long-term cost savings.

- Q: How do steel props compare to aluminum props in terms of performance?

- Steel props generally outperform aluminum props in terms of performance. Steel is a stronger and more durable material, allowing for higher thrust and better overall performance. Steel props also tend to be more resistant to damage and wear, making them a preferred choice for high-performance applications. However, aluminum props are lighter, which can provide advantages in terms of fuel efficiency and maneuverability. Ultimately, the choice between steel and aluminum props depends on the specific requirements and priorities of the application.

- Q: Can steel props be used for supporting temporary seating arrangements or bleachers?

- Yes, steel props can be used for supporting temporary seating arrangements or bleachers. Steel props are commonly used in construction and temporary structures due to their strength and stability.

- Q: What are the safety measures of steel support construction

- Improve the system, strengthen management, to solve the construction of the following work and problems: 1, regulate the side of the entrance and exit protection. Pay attention to wear safety helmet and high operating safety belt; according to the provisions of the use of qualified safety nets, safety helmets and seat belts

- Q: Are steel props adjustable with remote control mechanisms?

- No, steel props are not typically adjustable with remote control mechanisms. They are usually manually adjusted by hand or with the use of mechanical tools.

- Q: Can steel props be used in hospital renovation projects?

- Hospital renovation projects can indeed utilize steel props. These props are frequently employed in construction and renovation endeavors to afford temporary support to structures. Their adjustability and ease of installation render them well-suited for a range of applications, including hospital renovations. By using steel props, ceilings, walls, and floors can be adequately supported during renovation work, guaranteeing the security and stability of the building. Moreover, their height can be adjusted to meet specific requirements, thereby offering flexibility in accommodating diverse project needs. Consequently, steel props stand as a dependable and effective solution for hospital renovation projects.

Send your message to us

Tripod & Beam Clamp for building construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches