Hot Rolled MS Mild Light Steel Rails for Mines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled MS Mild Light Steel Rails for Mines at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Product Advantages:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

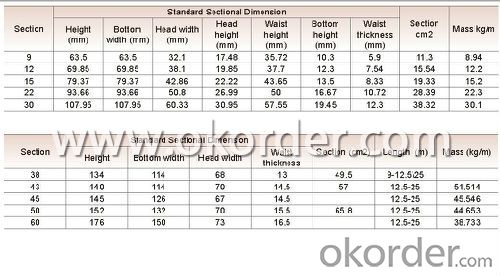

Product Specifications:

Product Name: High Quality Steel Rail

Production Standard: GB, AREMA, JIS, DIN, EN, UIC, BS, etc.

Grade: Q235B, 55Q, 900A, 1100A, 50MN, U71MN, R260.

Place of Origin: China

Length: 6M-24M according to the requriements of the customers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel channels perform in seismic conditions?

- Due to their superior strength and durability, steel channels are widely used in construction projects. They have proven to be highly effective in providing structural stability and resistance against earthquakes. One major advantage of steel channels in seismic conditions is their ability to flex and dissipate energy during an earthquake. This flexibility allows the channels to absorb seismic forces and prevent significant damage to the overall structure. Steel channels are designed to bend and deflect under stress, distributing seismic energy throughout the entire building system. Additionally, steel channels have high stiffness and strength, enabling them to withstand lateral forces generated during an earthquake. Their rigidity helps maintain the structural integrity of the building, reducing the risk of collapse or severe damage. Steel channels are also known for their excellent ductility, meaning they can deform without breaking. This property is highly beneficial in seismic conditions as it allows the channels to absorb and dissipate seismic energy without undergoing brittle fracture. This enhances the safety of the structure and provides a higher level of resilience against earthquakes. Moreover, steel channels can be easily reinforced and retrofitted to improve their seismic performance. Additional bracing or diagonal members can be installed to further enhance the strength and stiffness of the structure. This adaptability makes steel channels suitable for both new construction projects and retrofitting existing structures to meet seismic codes. In conclusion, steel channels are highly effective in seismic conditions. Their flexibility, strength, ductility, and adaptability make them a preferred choice for structures in earthquake-prone areas. By effectively absorbing and dissipating seismic energy, steel channels provide enhanced structural stability, minimizing the risk of damage or collapse during an earthquake.

- Q: Can steel channels be used for architectural purposes?

- Yes, steel channels can be used for architectural purposes. Steel channels are versatile and can be utilized in many architectural applications such as the construction of building frames, support structures, and architectural facades. They provide strength and stability to the overall structure, making them ideal for architectural projects where durability and load-bearing capacity are important considerations. Steel channels also offer flexibility in design as they can be easily fabricated and customized to meet specific architectural requirements. Moreover, their sleek and modern appearance can enhance the aesthetic appeal of a building, making them a popular choice among architects and designers. Overall, steel channels are a reliable and practical option for architectural purposes.

- Q: What are the weight calculations for steel channels?

- To determine the weight of steel channels, one can utilize the following formula: Weight can be found by multiplying the cross-sectional area with the density of steel. The cross-sectional area of a steel channel can be determined by multiplying the width (W), height (H), and thickness (T) of the web. In the case of tapered flanges, the average width (Wa) of the flanges should be employed. To calculate the cross-sectional area, add twice the average width of the flanges to the width, multiply the sum by the height, and add the product of the thickness and width. The density of steel typically measures approximately 7,850 kilograms per cubic meter (kg/m³). Hence, the weight of the steel channel can be established by multiplying the cross-sectional area by the density of steel. To ensure accurate weight calculations, it is crucial to employ consistent units for all measurements, such as meters or millimeters. Additionally, it is advisable to verify the specific dimensions and specifications of the steel channel being utilized, as they may vary.

- Q: What are the load-bearing capabilities of steel channels?

- Steel channels have high load-bearing capabilities due to their structural design and material strength. The load-bearing capacity of steel channels depends on various factors such as the size, shape, and thickness of the channel, as well as the type of steel used. However, in general, steel channels are known for their ability to support heavy loads and are commonly used in construction and engineering projects where strength and durability are crucial.

- Q: How do steel channels contribute to building durability?

- Steel channels contribute to building durability in several ways. Firstly, they provide structural support and reinforcement to the building, enhancing its overall strength and resistance to external forces such as wind, earthquakes, or heavy loads. Additionally, steel channels are highly durable themselves, as they are made from high-quality steel that is resistant to corrosion, decay, and pests. This ensures that the channels maintain their structural integrity over time, contributing to the long-term durability of the building. Lastly, steel channels also facilitate the installation and integration of various building systems, such as electrical, plumbing, or HVAC, further enhancing the overall efficiency and durability of the building.

- Q: What is the difference between hot-rolled and cold-formed steel channels?

- Hot-rolled and cold-formed steel channels are two distinct manufacturing processes that result in different properties and characteristics of the final product. Hot-rolled steel channels are produced by heating a steel billet or slab above its recrystallization temperature and then passing it through a series of rollers to achieve the desired shape. This process allows for the formation of larger and thicker sections with a uniform grain structure. Hot-rolled channels tend to have rounded corners and a rougher surface texture. They are typically used in structural applications where strength and load-bearing capacity are essential, such as in the construction of buildings, bridges, and heavy machinery. On the other hand, cold-formed steel channels are created by bending or folding a flat steel sheet or strip at room temperature. This process involves passing the steel through a series of rollers or press brakes to achieve the desired shape. Unlike hot-rolled channels, cold-formed channels have sharp corners and a smoother surface finish. They are typically thinner and lighter than hot-rolled channels and are commonly used in applications that require precision, flexibility, and cost-effectiveness. Cold-formed channels are often utilized in the construction industry for framing systems, wall studs, and various architectural elements. In summary, the main differences between hot-rolled and cold-formed steel channels lie in their manufacturing processes, physical characteristics, and typical applications. Hot-rolled channels offer greater strength and load-bearing capacity, while cold-formed channels are more lightweight, precise, and cost-effective. The choice between the two depends on the specific requirements of the project and the desired properties of the channel.

- Q: Are steel channels compatible with other building materials?

- Steel channels, when it comes to other building materials, are indeed compatible. In construction projects, steel channels are frequently employed as structural support elements and can be effortlessly integrated with various building materials like concrete, wood, and even other metals. To illustrate, steel channels can be incorporated into concrete structures to provide supplementary reinforcement and strength. In a building's framework, they can also serve to connect and support wooden beams or trusses. Furthermore, steel channels can be joined together with other steel components through welding or bolting, enabling the creation of intricate and adaptable structures. This compatibility with other building materials has made steel channels a favored option in construction projects, as they can readily be combined with different materials to meet specific design and engineering requirements.

- Q: Can steel channels be used for balcony railings?

- Yes, steel channels can be used for balcony railings. Steel channels are strong and durable, making them suitable for providing support and safety on balconies. They can be customized to fit the specific dimensions and design requirements of the balcony. Additionally, steel channels are corrosion-resistant and can withstand harsh weather conditions, making them a reliable choice for outdoor applications. Whether it is for residential or commercial purposes, steel channels offer a versatile and aesthetically pleasing option for balcony railings.

- Q: Are steel channels suitable for load-bearing applications?

- Yes, steel channels are suitable for load-bearing applications. They possess high strength and durability, making them capable of handling heavy loads and providing structural support in various construction projects. Additionally, steel channels offer versatility and can be easily customized to meet specific load-bearing requirements.

- Q: How do steel channels contribute to building security?

- Steel channels contribute to building security by providing structural support and reinforcement. They are commonly used in the construction of walls, floors, and roofs to enhance the overall strength and stability of the building. Steel channels help distribute the weight and loads evenly, making the structure more resistant to external forces such as strong winds, earthquakes, or impact. Additionally, they can be integrated with security systems to serve as barriers, preventing unauthorized access and enhancing the physical security of the building.

Send your message to us

Hot Rolled MS Mild Light Steel Rails for Mines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords