Hot Rolled MS Mild JIS Steel U Channels for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

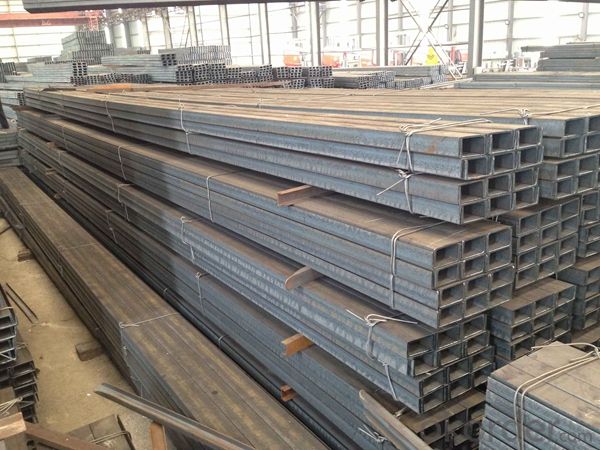

OKorder is offering Hot Rolled MS Mild JIS Steel U Channels for Strcutures at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are ideal for structural applications and general fabricating. The steel u channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc. In details, the steel u channel belongs to carbon structural steel which is applied to in the field of construction and machinery. The steel u channel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the steel u channel must possess perfect welding property, riveting property and mechanical property and so on.

Product Advantages:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Steel U Channel Details:

Minimum Order Quantity: 25 Tons Unit: m.t. Loading Port: Xingang Port

Supply Ability: 1000 Tons Per Day Payment Terms: TT or L/C

Product Description:

Specifications of Steel U Channel:

Standard Applied: GB Standard, EN Standard(UPN), JIS Standard

Sizes: 50mm to 300mm

Material Grade: Q235B, Q345B, S235JR, SS400, ASTM A36

As shown in the figure:

| JIS U CHANNEL | Standard h | Sectional b | Dimension s | t | Mass: Kg/m |

| (mm) | (mm) | (mm) | (mm) | ||

| 50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

| 75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

| 75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

| 75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

| 75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

| 100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

| 100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

| 100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

| 100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

| 125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

| 125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

| 125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

| 125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

| 150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

| 150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

| 150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

| 150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel channels contribute to the overall safety of a structure?

- Steel channels contribute to the overall safety of a structure in several ways. Firstly, steel channels provide structural support and stability to the building. They are often used as load-bearing members in the construction industry, helping to distribute the weight of the structure evenly and efficiently. This ensures that the building can withstand various external forces such as wind, earthquakes, and heavy loads without collapsing. By providing a strong framework, steel channels enhance the overall safety and structural integrity of the building. Secondly, steel channels play a crucial role in fire safety. Steel is a non-combustible material, and when used as channels, it can help prevent the spread of fire within a structure. In the event of a fire, steel channels act as fire barriers, restricting the movement of flames and heat to specific areas. This containment helps to limit the damage caused by fire and provides occupants with more time to evacuate safely. Additionally, steel channels are resistant to corrosion and deterioration, making them highly durable and reliable. Unlike other materials, steel does not rot, warp, or degrade over time. This longevity ensures that the structure remains stable and secure in the long run, reducing the risk of accidents and structural failures. Furthermore, steel channels are often used in the construction of seismic-resistant structures. With their high strength and flexibility, steel channels can absorb and dissipate seismic energy during an earthquake. This ability to withstand seismic forces helps to minimize structural damage and ensures the safety of the occupants within the building. In conclusion, steel channels contribute significantly to the overall safety of a structure by providing structural support, fire resistance, durability, and seismic resistance. Their use in construction enhances the stability, strength, and integrity of the building, ensuring the safety and well-being of its occupants.

- Q: Can steel channels be used for ceiling installations?

- Indeed, ceiling installations can make use of steel channels. In construction, steel channels are widely employed due to their robustness and longevity. They serve as a reliable and steady foundation for hanging or attaching different elements of a ceiling system, such as electrical fixtures, HVAC ducts, and acoustic panels. Moreover, steel channels facilitate effortless installation and adjustment, rendering them highly favored for both residential and commercial ceiling projects. Furthermore, they possess exceptional load-bearing capabilities, guaranteeing the steadfastness and safety of the ceiling structure.

- Q: How do steel channels contribute to fire resistance in buildings?

- Steel channels contribute to fire resistance in buildings by providing structural stability and preventing the collapse of the building during a fire. They act as reinforcements within the building's framework, enhancing its ability to withstand high temperatures and preventing the spread of fire. Steel channels are designed to retain their strength even when exposed to extreme heat, which helps to maintain the structural integrity of the building and allows occupants more time to evacuate safely.

- Q: How do steel channels contribute to the overall energy efficiency of a structure?

- Steel channels can contribute to the overall energy efficiency of a structure in several ways. Firstly, steel channels are commonly used in the construction of walls and roofs. These channels provide structural support and help distribute the weight of the building evenly. By using steel channels, the overall weight of the structure can be reduced, leading to lower energy consumption during construction and throughout the building's lifespan. Additionally, steel channels can be designed to provide insulation properties. Thermal bridging is a common issue in buildings where heat is transferred through materials that have higher thermal conductivity. However, steel channels can be engineered to minimize thermal bridging by incorporating insulation materials or thermal breaks. This reduces the transfer of heat between the interior and exterior of the building, resulting in improved energy efficiency. Furthermore, steel channels are known for their durability and strength. This allows for the construction of larger spans and open spaces, reducing the need for additional support columns or walls. By maximizing the use of open spaces, natural light and ventilation can be optimized, reducing the reliance on artificial lighting and mechanical HVAC systems. This not only decreases energy consumption but also enhances the overall comfort and well-being of the occupants. Lastly, steel channels have the advantage of being recyclable. Steel is one of the most recycled materials in the world, and using recycled steel channels in construction can significantly reduce the environmental impact of building projects. The energy required to produce recycled steel is much lower compared to virgin steel production, further contributing to the overall energy efficiency of the structure. In conclusion, steel channels contribute to the overall energy efficiency of a structure by reducing weight, minimizing thermal bridging, enabling open spaces for natural lighting and ventilation, and being recyclable. By incorporating steel channels in construction, buildings can achieve better energy performance, reducing energy consumption, and promoting sustainability.

- Q: What are the different methods of strengthening steel channels against bending?

- To enhance the resistance of steel channels against bending, there are multiple approaches that can be employed: 1. Augmenting the cross-sectional area of the channel: One effective way to strengthen a steel channel is by increasing its cross-sectional area. This can be accomplished by utilizing a thicker channel or incorporating supplementary steel plates or sections to expand the overall area. 2. Employing reinforcement plates or stiffeners: By attaching reinforcement plates or stiffeners to the weak points of the channel, its ability to withstand bending can be significantly improved. These plates or stiffeners are typically welded to the channel and aid in distributing the applied loads more uniformly, thus reducing the risk of bending. 3. Introducing flanges or lips: Another viable method involves adding flanges or lips to the edges of the channel. These supplementary steel sections enhance the rigidity of the channel, rendering it more resistant to bending. 4. Implementing bracing or truss systems: Bracing or truss systems can be utilized to provide support to the steel channel and prevent bending. These systems consist of additional steel members, such as braces or trusses, that are connected to the channel to offer extra support and distribute the applied loads. 5. Utilizing heat treatment: Heat treatment techniques like quenching and tempering can be employed to fortify the steel channel. These processes involve heating the channel to a specific temperature and then rapidly cooling it to increase its hardness and strength. 6. Employing cold working techniques: Cold working techniques like cold rolling or cold drawing can also be used to strengthen steel channels against bending. These processes involve shaping the channel at low temperatures, thereby enhancing its strength and toughness. It is important to note that the choice of method depends on various factors, including the specific application, the desired level of strength, and the available resources and equipment. It is advisable to consult with a structural engineer or steel fabrication expert to determine the most suitable method for strengthening steel channels against bending in a particular situation.

- Q: How do steel channels compare to other building materials?

- Steel channels are highly regarded in the construction industry due to their exceptional strength, durability, and versatility. Compared to other building materials like wood or concrete, steel channels offer superior resistance to fire, corrosion, and pests. They also have a higher load-bearing capacity, allowing for greater design flexibility and the ability to construct larger and more complex structures. Additionally, steel channels are known for their consistency in quality and precision, making them a preferred choice for many builders and architects.

- Q: Can steel channels be used for material handling systems?

- Yes, steel channels can be used for material handling systems. Steel channels are commonly used in industrial applications due to their strength, durability, and versatility. They can be used to create support structures, frames, and beams for material handling systems such as conveyor belts, overhead cranes, and storage racks. Steel channels provide excellent load-bearing capabilities and can withstand heavy loads and impacts, making them suitable for handling and transporting various materials in industrial settings. Additionally, steel channels can be easily fabricated, modified, and installed, allowing for customized material handling solutions to be created based on specific requirements.

- Q: Can steel channels be used for supporting staircases?

- Indeed, staircases can be supported using steel channels. In construction, steel channels are widely employed due to their robustness and endurance. They offer exceptional support and stability, rendering them appropriate for withstanding the load of staircases while safeguarding their structural soundness. Furthermore, steel channels can be effortlessly tailored and manufactured to meet precise design specifications, thus establishing them as a flexible option for supporting staircases.

- Q: Are steel channels suitable for agricultural buildings?

- Yes, steel channels are suitable for agricultural buildings. Steel channels offer several advantages that make them ideal for agricultural structures. Firstly, steel channels are known for their high strength and durability. They can withstand heavy loads and harsh weather conditions, making them suitable for supporting the weight of agricultural equipment, storing feed, and withstanding the elements. Additionally, steel channels are resistant to pests, such as termites and rodents, which are common in agricultural environments. This makes them a more reliable and long-lasting option compared to other materials that may be susceptible to pest damage. Moreover, steel channels are fire-resistant, reducing the risk of damage or loss in the event of a fire outbreak, which is crucial for the safety of livestock and stored crops. Furthermore, steel channels are highly versatile and can be easily customized to suit the specific needs of agricultural buildings. They can be designed to accommodate various layouts and configurations, allowing for efficient use of space and optimal functionality. Lastly, steel channels require minimal maintenance over their lifespan, reducing the overall cost of ownership for agricultural buildings. This is particularly beneficial in the agricultural sector, where time and resources are often limited. Considering these factors, it is clear that steel channels are a suitable and advantageous choice for agricultural buildings, providing strength, durability, versatility, and cost-effectiveness.

- Q: Can steel channels be customized according to specific requirements?

- Indeed, specific requirements can be accommodated through the customization of steel channels. In the construction and manufacturing industries, steel channels find widespread use for framing, support, and reinforcement purposes. These channels can be tailored to meet precise project specifications in terms of size, shape, length, thickness, and material composition. By customizing steel channels, a higher degree of flexibility and adaptability can be achieved in diverse applications. For example, the channel's dimensions and form can be modified to align with specific structural designs or to withstand particular loads and stresses. The channel's length can be personalized to suit the project's dimensions, while the thickness can be adjusted to provide the desired strength and durability. Moreover, material composition is another aspect that can be customized for steel channels. Depending on the project's requirements, various steel types, including carbon steel, stainless steel, or alloy steel, can be employed. This customization ensures that the steel channel possesses the necessary properties, such as corrosion resistance, heat resistance, or high tensile strength, to successfully endure the intended application. In summary, steel channels can undoubtedly be customized to cater to specific requirements, offering a versatile solution for a wide range of construction and manufacturing needs.

Send your message to us

Hot Rolled MS Mild JIS Steel U Channels for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords