Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

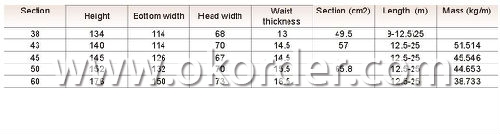

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Production Standard: GB2585-81, AREMA, DIN, JIS, EN, etc.

Length: 6M-25M as the requriement of the client

Material: 50Mn, U71Mn, 900A, R260, etc.

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

U71Mn

|

0.65—0.76 |

1.10—1.40 |

≤0.030 |

≤0.035

|

0.15-0.35

|

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track. Be used for railway, subway, curve way, tunnel way, etc.

Packaging & Delivery of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: Why buy Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What is the normal tolerance of Hot Rolled Mild Steel Angle Beams for Structures and for Buildings?

A3: Normally 3%-5%, but we can also produce the goods according to the customers' request

- Q: What are the different methods of measuring rail stability and alignment using steel rails?

- There are several methods used to measure rail stability and alignment using steel rails. One common method is the use of track geometry cars equipped with laser or optical sensors. These cars travel on the rails and collect data on parameters such as track gauge, cross-level, and alignment. Another method is the use of track inspection vehicles that utilize accelerometers and other sensors to monitor rail movement and identify any deviations from the desired alignment. Additionally, manual measurements using tools like gauges and levels can be carried out by trained personnel to assess rail stability and alignment.

- Q: How do steel rails contribute to the efficiency of railway systems?

- Steel rails contribute to the efficiency of railway systems in several ways. Firstly, steel rails provide a smooth and durable surface for train wheels to run on, minimizing friction and allowing trains to travel at high speeds with reduced energy consumption. Secondly, steel rails offer excellent strength and load-bearing capacity, ensuring the safe movement of heavy trains and enabling the transportation of large quantities of goods and passengers. Additionally, steel rails require minimal maintenance and have a long lifespan, reducing downtime and costs associated with repairs and replacements. Overall, steel rails play a crucial role in optimizing the efficiency and productivity of railway systems.

- Q: What are the specifications for steel rail trackside communication systems?

- The specifications for steel rail trackside communication systems typically include factors such as reliable wireless connectivity, high data transmission speeds, resistance to harsh environmental conditions, compatibility with various communication protocols, and the ability to handle large amounts of data for efficient train control and monitoring.

- Q: What are the safety measures for working on curved steel rail tracks?

- When working on curved steel rail tracks, it is important to adhere to several safety measures. Firstly, workers should always wear appropriate personal protective equipment (PPE), such as steel-toed boots, high visibility clothing, and safety glasses. They should also be trained on the proper use of tools and equipment, and follow all established safety procedures. Additionally, workers should be cautious of the curved track's geometry and take necessary precautions to maintain balance and stability while working. Regular inspections of the track, including checking for any defects or obstructions, should be conducted to ensure a safe working environment. Overall, prioritizing safety, being mindful of the track's unique characteristics, and following established protocols are crucial safety measures when working on curved steel rail tracks.

- Q: What is the role of steel rails in providing a reliable train infrastructure?

- The role of steel rails in providing a reliable train infrastructure is crucial. Steel rails serve as the foundation upon which trains travel, providing a smooth and stable track for them to operate on. The durability and strength of steel make it ideal for withstanding the heavy weight and constant impact of trains, ensuring the tracks remain intact and safe for train operation. Additionally, steel rails offer excellent resistance to wear and tear, reducing the need for frequent maintenance and enhancing the longevity of the infrastructure. Overall, steel rails play a vital role in creating a reliable train infrastructure by providing a sturdy and dependable track system.

- Q: What are the considerations for using steel rails in coastal areas prone to saltwater corrosion?

- When evaluating the utilization of steel rails in coastal regions susceptible to saltwater corrosion, several aspects must be taken into consideration. 1. Resistance to Corrosion: One of the key factors to consider is the steel's ability to resist corrosion. Stainless steel, which contains chromium and other alloying elements, is commonly employed in coastal areas due to its exceptional resistance to corrosion. It forms a passive oxide layer that shields the steel from exposure to saltwater. 2. Application of Coating and Paint Systems: The application of a suitable coating or paint system can further enhance the corrosion resistance of steel rails. These protective systems act as a barrier between the steel and the corrosive saltwater environment. The coating or paint must be specifically designed for coastal use and should undergo regular inspection and maintenance. 3. Selection of Materials: The choice of steel for the rails is of utmost importance. Weathering steel, also known as COR-TEN steel, is often recommended for coastal regions as it develops a protective rust-like appearance that decelerates the corrosion process. However, it is imperative to ensure that the rail's mechanical properties meet the required safety standards. 4. Design and Maintenance: Proper design and maintenance practices are essential for the durability of steel rails in coastal areas. Measures such as appropriate drainage, avoidance of stagnant water, and regular cleaning can help prevent the accumulation of salt deposits and decrease the risk of corrosion. Periodic inspections and maintenance should also be carried out to promptly identify any signs of corrosion and take appropriate action. 5. Environmental Factors: Aside from saltwater exposure, other environmental factors such as humidity, temperature, and pollution levels can impact corrosion. Understanding these factors and their influence on steel rails is crucial in determining the suitable corrosion protection measures. 6. Life Cycle Costs: It is important to consider the long-term expenses associated with using steel rails in coastal areas. Although stainless steel or weathering steel may have higher initial costs, their superior resistance to corrosion can result in lower maintenance and replacement expenditures over time. By taking all these factors into account, engineers and decision-makers can make well-informed choices regarding the utilization of steel rails in coastal regions prone to saltwater corrosion.

- Q: Are steel rails used for both heavy and light rail systems?

- Yes, steel rails are commonly used for both heavy and light rail systems.

- Q: Are steel rails used in airport people movers?

- Yes, steel rails are commonly used in airport people movers.

- Q: What are the safety measures for steel rail construction near water bodies?

- Some safety measures for steel rail construction near water bodies include implementing proper erosion control measures, conducting regular inspections of the construction site to ensure stability, using appropriate barriers or fencing to prevent accidental falls into the water, providing adequate signage and warning signals for workers and pedestrians, and following all relevant safety regulations and guidelines set by local authorities. Additionally, workers should receive proper training and be equipped with necessary safety gear such as life jackets or personal flotation devices when working near or over water bodies.

- Q: How are steel rails installed on railway tracks?

- Steel rails are installed on railway tracks through a process called track laying. First, the ground is prepared by removing any debris or old rails. Then, the rail sections are aligned on the sleepers and joined together using fishplates and bolts. The rails are then lifted and placed onto the sleepers using heavy machinery or manual labor. Finally, the rails are securely fastened to the sleepers using clips or screws, ensuring a sturdy and stable track for trains to run on.

Send your message to us

Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords