Hot Rolled Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

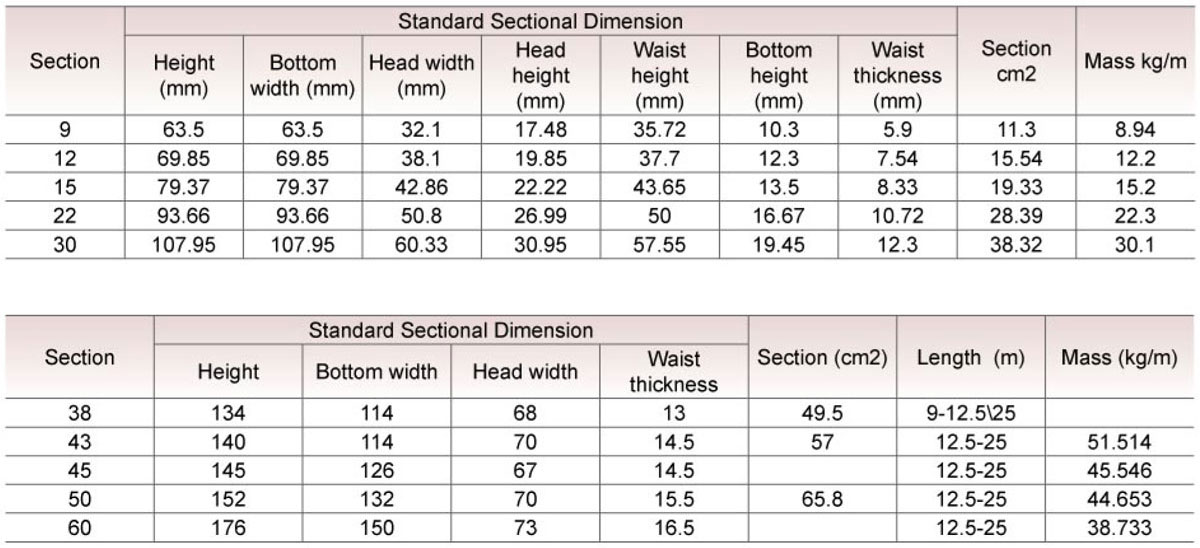

Specifications of Hot Rolled Steel Rail

Production Standard: GB Standard, AREMA, BS, UIC860, JIS, DIN, etc

Grade: Q235B, 55Q, 900A, 50Mn, U71Mn

| Alloy No. | Grade | C | Mn | S | P | Si |

| Q235 | B | 0.12%-0.20 | 0.3%-0.7% | <=0.045% | <=0.045% | <=0.3% |

Length: 6M, 8M, 9M, 10M, 12M, 12.5M, 24M or as the requriements of the client

Sizes: 9kg-60kg

Usages of Hot Rolled Steel Rail

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Packaging & Delivery of Hot Rolled Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of Hot Rolled Steel Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: What is the role of steel rails in reducing track maintenance costs?

- Steel rails play a crucial role in reducing track maintenance costs by providing durability, strength, and stability to the railway infrastructure. The use of steel rails ensures a smooth and stable surface for trains to travel on, minimizing wear and tear on the tracks. This reduces the frequency of maintenance and repair work required, leading to cost savings for railway operators. Additionally, steel rails have a longer lifespan compared to other materials, further reducing the need for frequent replacements and associated expenses.

- Q: How do steel rails contribute to track stability?

- Steel rails contribute to track stability in several ways. Firstly, steel rails provide a strong and rigid structure for the train tracks. The steel material is highly durable and has excellent strength-to-weight ratio, which allows it to withstand the heavy loads and forces exerted by the passing trains. This structural integrity prevents the tracks from deforming or bending under the weight of the trains, ensuring stability and safety. Secondly, steel rails provide a smooth and even surface for the train wheels to roll on. The flat and polished top surface of the rails reduces friction and allows the wheels to move freely, minimizing any lateral movement or wobbling. This smooth running surface promotes stability by preventing the train from derailing or moving off track. Furthermore, steel rails are designed with specific profiles that contribute to track stability. The shape of the rail, such as the head, web, and base, is carefully engineered to distribute the weight of the train evenly and efficiently. This distribution of weight helps to maintain balance and stability along the entire length of the track. Additionally, steel rails are securely fastened to the sleepers or ties, which are further anchored to the ground. This fixed attachment ensures that the rails remain in their proper position, preventing any lateral movement or shifting. The stability provided by the secure fastening of the rails contributes to the overall stability of the track. Overall, steel rails play a crucial role in maintaining track stability by providing a strong and rigid structure, smooth running surface, carefully engineered profiles, and secure fastening. These features work together to ensure that the trains can travel safely, smoothly, and without derailment or instability.

- Q: How are steel rails protected from weathering?

- Corrosion prevention is the method utilized to protect steel rails from weathering. This process entails the application of diverse protective coatings onto the rail's surface, functioning as a barrier against moisture, oxygen, and other corrosive elements present in the surroundings. Zinc is the most frequently employed coating for steel rails, and it is applied through a method known as galvanization. During galvanization, the rail is submerged in a bath of molten zinc, forming a protective layer over the steel surface. This zinc coating not only prevents direct contact between the steel and the environment but also acts as a sacrificial layer. In the presence of moisture or other corrosive agents, the zinc coating corrodes instead of the steel. Furthermore, regular maintenance and inspection of the rails are conducted to promptly detect any signs of corrosion or damage and address them before they worsen. Overall, these protective measures guarantee the durability and resistance to weathering of steel rails, which in turn extends their lifespan and upholds the safety and efficiency of railway systems.

- Q: What are the different types of rail switches used with steel rails?

- There are several different types of rail switches that are commonly used with steel rails. These switches are designed to allow trains to change tracks or move between different lines. 1. Turnouts: Turnouts, also known as switches or points, are the most commonly used type of rail switch. They consist of movable rails that can be aligned to divert a train from one track to another. Turnouts are typically used at junctions or where two tracks merge or diverge. 2. Crossovers: Crossovers are another type of rail switch used with steel rails. They allow trains to move from one track to another parallel track. Crossovers are often used to provide flexibility in train operations, allowing trains to switch tracks for various reasons such as bypassing a section of track or accessing a different platform. 3. Diamond crossings: Diamond crossings are rail switches that allow trains to cross each other at a junction without the need for a curved track. They are called diamond crossings because of their diamond-shaped layout, with two tracks intersecting each other diagonally. Diamond crossings are commonly used in complex rail networks with multiple lines intersecting. 4. Slip switches: Slip switches, also known as catch points or derailers, are used to prevent trains from accidentally entering tracks that are out of service or undergoing maintenance. They consist of a movable rail that can be aligned to force a train to move onto a separate track or into a safe area. Slip switches are an important safety feature in rail infrastructure. 5. Gauntlet tracks: Gauntlet tracks are a type of rail switch used in situations where space is limited or in urban areas. They consist of two tracks that overlap each other, allowing trains to pass in opposite directions on a shared section of track. Gauntlet tracks are commonly used in situations where it is not feasible to construct separate tracks for each direction. These are just a few examples of the different types of rail switches used with steel rails. Each type serves a specific purpose and is designed to provide flexibility and safety in train operations. The choice of rail switch depends on the specific requirements of the rail network and the location where it is being installed.

- Q: Are steel rails prone to buckling under extreme heat?

- Steel rails are susceptible to buckling in extreme heat. When steel is subjected to high temperatures, it expands and contracts as it cools. If the temperature of the steel rail rises significantly, its expansion may cause it to buckle or become distorted. This occurrence is referred to as thermal buckling. The rail's expansion can generate compression forces that surpass its ability to endure, resulting in deformation and possibly even failure. To prevent buckling, railways employ several measures, including the installation of expansion joints, the utilization of continuous welded rail, and the regular monitoring of rail temperatures to guarantee safety and avoid accidents.

- Q: Can steel rails be used in railway systems with steep gradients?

- Steel rails are indeed suitable for use in railway systems that have steep gradients. They are widely utilized in railway systems across the globe due to their impressive strength and durability. Even on steep gradients, they possess the ability to bear heavy loads and impart stability to the trains. However, the safe and efficient operation of railway systems with steep gradients necessitates meticulous consideration and engineering proficiency in their design and construction. This entails taking into account factors such as track alignment, gradient profiles, as well as the incorporation of supplementary safety measures like brakes and traction systems. By undertaking thorough planning and execution, steel rails can effectively surmount the challenges presented by steep gradients in railway systems.

- Q: What are the safety precautions for workers during steel rail welding?

- To ensure the well-being of workers during steel rail welding, it is important to follow several safety precautions: 1. Personal Protective Equipment (PPE) should be worn by workers. This includes flame-resistant clothing, safety goggles, gloves, and steel-toed boots. These protective measures will prevent injuries from sparks, molten metal, and other potential hazards. 2. Proper ventilation is crucial to minimize exposure to welding fumes and gases. The work area should be well-ventilated, or local exhaust ventilation systems can be used to remove fumes and maintain clean air. 3. Welding curtains or screens should be installed around the work area to shield nearby workers from arc radiation, sparks, and splatter. This will prevent eye injuries and burns. 4. Fire safety measures should be implemented. Fire extinguishers should be readily available, and workers should be trained in their usage. Flammable materials should be removed from the welding area, and a clear evacuation plan should be established in case of fire. 5. Proper grounding of welding equipment and workpieces is necessary to prevent electric shock hazards. Regular inspections of cables and connections should be conducted to ensure they are in good condition. 6. Workers should receive proper training and certification in welding techniques and safety protocols before starting any welding tasks. They should be competent and certified to perform the required welding operations. 7. Workers should be aware of potential hazards, such as arc flashes, electric shock, and burns. They should exercise caution while handling equipment, avoid touching live parts, and follow lockout/tagout procedures when necessary. 8. Regular inspections and maintenance of welding equipment are essential to ensure they are in proper working condition. Faulty equipment can pose serious safety risks, so prompt repairs or replacements may be necessary. 9. Emergency preparedness is crucial. A well-equipped first aid kit should be available on-site, and workers should be trained in basic first aid procedures. Clear communication channels and emergency response protocols should be established to address any accidents or injuries promptly. By following these safety precautions, the risk of accidents, injuries, and health hazards associated with steel rail welding can be significantly reduced.

- Q: What are the different grades of steel used in rails?

- Rails are made using various grades of steel, each with its own unique properties and characteristics. The most commonly used grades for rail manufacturing are as follows: 1. Grade 700: This is the top-tier steel grade employed in rails, renowned for its exceptional strength and durability. It finds application in heavy-duty railways and high-speed train tracks that endure substantial loads and stresses. 2. Grade 600: Another high-strength grade, often utilized in railway tracks with heavy traffic. It offers good resistance to wear and can withstand the forces exerted by passing trains. 3. Grade 400: This grade of steel is typically used in light to medium-duty railway tracks. Although its strength is lower compared to grades 600 and 700, it is suitable for tracks with lower traffic loads. 4. Grade 250: This lower grade of steel is utilized in railways that require lighter-duty tracks, such as tramways or light rail systems. It possesses lower strength and wear resistance than higher grades but is adequate for tracks with lower traffic volumes. 5. Grade R260: This grade of steel is commonly employed in European railways. It strikes a good balance between strength, wear resistance, and cost-effectiveness, making it suitable for a wide array of rail applications. It should be noted that the specific grades of steel used in rails may differ based on the country and railway system. Furthermore, factors such as track design, traffic volume, and environmental conditions also play a role in determining the suitable steel grades for rail construction.

- Q: How are steel rails maintained?

- Steel rails are maintained through regular inspections, cleaning, and repairing of any defects or damages. This includes removing debris, lubricating the tracks, and inspecting for wear and tear. Additionally, rails may undergo periodic grinding or replacement to ensure a smooth and safe train operation.

- Q: What is the purpose of steel rails in railway systems?

- The purpose of steel rails in railway systems is to provide a sturdy and durable track for trains to travel on. Steel rails offer high strength and resistance to wear and tear, allowing trains to run smoothly and efficiently. They provide stability, guidance, and support to the train, ensuring safe and reliable transportation.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Hot Rolled Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords