Steel Light Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

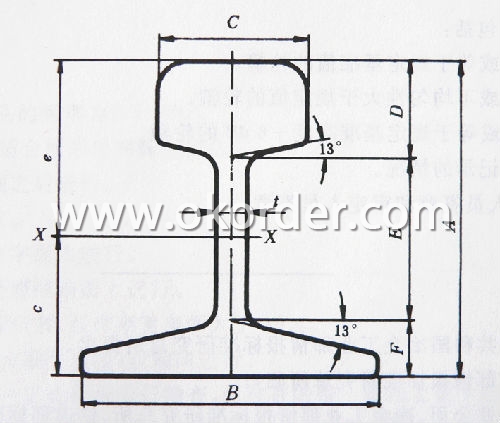

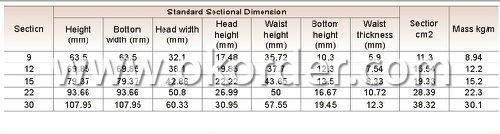

Specifications of Steel Light Rail

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Material: Q235B, 55Q, 900A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Steel Light Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

railway, subway, transportation track, express, curve way, tunnel way.

Packaging & Delivery of Steel Light Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, material, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Steel Light Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Steel Light Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: How are steel rails anchored to the ground?

- Steel rails are typically anchored to the ground using a combination of concrete sleepers or ties, rail clips, and spikes or bolts. The sleepers, made of concrete, are laid on a prepared bed of crushed stone or ballast. The steel rails are then secured to the sleepers using rail clips, which hold the rails firmly in place. Spikes or bolts are driven through holes in the clips and into the sleepers to provide additional stability and prevent movement. This anchoring system ensures that the steel rails remain secured to the ground, allowing trains to run smoothly and safely.

- Q: How do steel rails handle extreme weather conditions?

- Steel rails are designed to handle extreme weather conditions exceptionally well. They have high resistance to temperature fluctuations, which helps them withstand freezing temperatures, intense heat, and rapid temperature changes. Additionally, steel rails have good resistance to corrosion, ensuring their durability and reliability even in harsh weather conditions such as heavy rain or snow. Furthermore, they are engineered to maintain their structural integrity under varying weather conditions, minimizing the risk of deformation or damage. Overall, steel rails are built to withstand extreme weather and provide a safe and reliable transportation system.

- Q: How are steel rails affected by heavy loads?

- Steel rails are affected by heavy loads primarily through wear and deformation. The repeated pressure and friction from heavy loads can cause the rails to gradually wear down, leading to a decrease in their overall lifespan. Additionally, heavy loads can cause the rails to deform or bend slightly, which can affect their alignment and stability. Regular maintenance and inspection are essential to ensure the safety and longevity of steel rails under heavy loads.

- Q: How are steel rails protected against chemical exposures?

- Various methods are employed to safeguard steel rails against chemical exposures. One prevalent approach involves the utilization of corrosion-resistant coatings, which serve as a shield between the steel surface and the chemicals. This prevents direct contact and minimizes the likelihood of corrosion. An alternative method to shield steel rails from chemical exposures is through the usage of inhibitors. These chemicals can be introduced into the surroundings or applied directly onto the steel surface to impede the corrosion process. By forming a protective layer on the steel, inhibitors hinder the chemical reactions responsible for corrosion. Effective safeguarding of steel rails against chemical exposures also relies on regular maintenance and cleaning. Immediate removal of any chemical spills or leaks on the rails is imperative to prevent prolonged contact and potential corrosion. Moreover, routine cleaning aids in eliminating accumulated chemicals or contaminants that may contribute to corrosion over time. In certain cases, surface treatments such as galvanization or hot-dip coating may be employed on steel rails. These procedures involve the application of a zinc layer to the steel surface, creating a sacrificial barrier that corrodes in place of the steel. This sacrificial layer prevents direct contact between the steel and chemicals, thus extending the lifespan of the rails and reducing the risk of corrosion. In summary, the protection of steel rails against chemical exposures necessitates a combination of corrosion-resistant coatings, inhibitors, regular maintenance, and appropriate surface treatments. These measures ensure the durability and safety of steel rails in diverse environments.

- Q: How do steel rails handle changes in train acceleration?

- The purpose of steel rails is to effectively handle variations in train acceleration. Steel possesses desirable properties such as exceptional strength and durability, making it an ideal material for railway tracks. When a train accelerates, there is an increase in the force applied to the rails. However, steel has the capacity to withstand this force without any distortion or breakage. Flexibility is a significant characteristic of steel rails. They are designed to possess a certain level of flexibility, which accommodates alterations in train acceleration. This flexibility aids in evenly distributing the force exerted by the train along the length of the rails, thus preventing localized damage. Furthermore, steel rails are placed on a foundation of ballast, which not only offers additional support but also absorbs the impact caused by the train's acceleration. The ballast acts as a cushion and helps distribute the force exerted by the train over a larger surface area, minimizing the risk of rail damage. Additionally, regular maintenance and inspection of the rails are imperative to ensure their proper functionality in response to changing train accelerations. Prompt identification and resolution of any signs of wear, fatigue, or damage are necessary to uphold the integrity of the rails. In conclusion, steel rails are engineered to effectively handle variations in train acceleration. Their strength, flexibility, and the support provided by the ballast enable them to endure the forces exerted by accelerating trains without any distortion or damage. Regular maintenance and inspection are vital in guaranteeing the safe and efficient operation of steel rails.

- Q: What are the limitations of using steel rails in track construction?

- One limitation of using steel rails in track construction is their susceptibility to corrosion. Steel is prone to rusting when exposed to moisture and can weaken over time, leading to structural issues and potential derailments. Additionally, steel rails can be quite heavy, making them more difficult and costly to transport and install. They also have limited flexibility, which can cause increased wear and tear on the track and the wheels of the trains. Finally, steel rails can generate significant noise and vibration, which can affect the comfort of passengers and nearby residents.

- Q: Are steel rails affected by chemical spills or leaks?

- Yes, steel rails can be affected by chemical spills or leaks. Chemical substances can corrode the steel, compromising its structural integrity and potentially leading to accelerated wear and tear. It is crucial to promptly clean and remove any chemical spills or leaks on steel rails to prevent long-term damage and ensure safe operations.

- Q: How are steel rails used in tram and light rail systems?

- Steel rails are a critical component of tram and light rail systems, as they provide the necessary tracks for the vehicles to run on. These rails are carefully designed and constructed to withstand the weight and pressure exerted by the trams or light rail vehicles, ensuring a smooth and safe ride for passengers. In tram and light rail systems, steel rails are laid down in a predetermined path, forming a track network. Trams or light rail vehicles are equipped with wheels that are specifically designed to run on these rails. The wheels have flanges that fit into the grooves on the sides of the steel rails, preventing the vehicles from derailing and maintaining stability during operation. The steel rails themselves are made from high-quality steel, which is known for its strength, durability, and longevity. They are manufactured to precise specifications, including the size, shape, and profile of the rail, to ensure compatibility with the tram or light rail system. Steel rails are also subjected to regular maintenance and inspections to ensure their integrity. This includes checking for any signs of wear and tear, such as cracks or deformation, and addressing them promptly to prevent any potential accidents or disruptions to the system. Overall, steel rails are essential in tram and light rail systems as they provide the necessary infrastructure for the vehicles to travel on. Their strength, durability, and compatibility ensure safe and efficient transportation for commuters in urban areas.

- Q: How do steel rails handle the effects of track settlement and heave?

- Steel rails are designed to handle the effects of track settlement and heave quite effectively. Due to their strength and durability, steel rails can withstand the downward settlement of the track without significant deformation or damage. Additionally, their flexibility allows them to accommodate small degrees of track heave by adjusting their position slightly, minimizing the impact on train operations.

- Q: What are the benefits of using steel rails in high-speed train systems?

- There are several benefits of using steel rails in high-speed train systems. Firstly, steel rails provide a high level of durability and strength, making them capable of withstanding the heavy loads and stresses associated with high-speed trains. Steel is known for its excellent resistance to wear and tear, ensuring a longer lifespan for the rails compared to other materials. This durability also minimizes the need for frequent maintenance and replacement, resulting in cost savings for the train operators. Secondly, steel rails offer superior stability and track alignment, which is crucial for the safe and efficient operation of high-speed trains. The smooth surface of steel rails reduces friction and resistance, allowing the trains to travel at high speeds with minimal energy loss. This not only enhances the overall speed and performance of the trains but also reduces the overall energy consumption and carbon emissions. Additionally, steel rails provide excellent track geometry control, meaning they can maintain the precise alignment needed for high-speed operations. This ensures a smooth and comfortable ride for passengers, minimizing vibrations and noise levels. Steel rails also have a high resistance to deformation, preventing any track irregularities that could cause disruptions or accidents. Moreover, steel rails are highly compatible with advanced signaling and train control systems, allowing for more precise and efficient train operations. The steel material enables effective communication between the trains and the track infrastructure, facilitating high-speed train control and monitoring. Lastly, steel rails have a proven track record in high-speed train systems worldwide. They have been successfully used in numerous countries with extensive high-speed rail networks, such as Japan, China, and France. The experience and expertise gained from these systems make steel rails a reliable and trusted choice for implementing new high-speed train projects globally. In conclusion, the benefits of using steel rails in high-speed train systems include durability, stability, energy efficiency, passenger comfort, track geometry control, and compatibility with advanced train control systems. These advantages make steel rails an essential component in ensuring the safe, efficient, and reliable operation of high-speed trains.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Steel Light Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords