Hot Rolled Light Steel Rail with High Quality 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Light Steel Rail with High Quality 55Q at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Light Steel Rail with High Quality 55Q is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Product Advantages:

OKorder's Hot Rolled Light Steel Rail with High Quality 55Q are durable, strong, and with competitive price

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

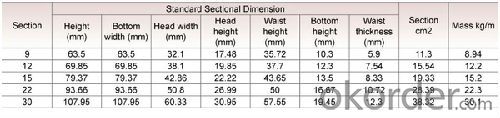

Product Specifications:

Manufacture: Hot rolled

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 25m, as per customer request

Packaging: Export packing, nude packing, bundled

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Sizes: 9kg-60kg

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4:What is the package

A4: Standard seaworthy packing or as customer required; all goods are packed in bundle with steel strips and shipped by break bulk vessel or container

Images:

.

- Q:Can steel rails be used in elevated railways or bridges?

- Yes, steel rails can be used in elevated railways or bridges. Steel rails are commonly used in these types of structures due to their strength, durability, and resistance to wear and tear. They can support heavy loads and provide a stable and secure track for trains or vehicles to travel on. Additionally, steel rails can withstand the environmental factors such as temperature variations and exposure to moisture, making them suitable for use in elevated railways and bridges.

- Q:How do steel rails handle changes in track alignment due to track settlement?

- Steel rails are designed to be flexible and resilient, allowing them to accommodate changes in track alignment caused by track settlement. They can withstand these changes without significant damage or deformation, ensuring the safe and smooth operation of trains.

- Q:What are the different rail profiles used in steel rails?

- There are several different rail profiles used in steel rails, including the flat bottom (FB), bullhead (BH), vignole (V), and grooved rail profiles. Each profile has its own specific design and is used for different purposes in rail infrastructure.

- Q:Can steel rails be used in temporary railway tracks?

- Yes, steel rails can be used in temporary railway tracks. Steel rails are commonly used in both permanent and temporary railway tracks due to their durability and strength. They can be easily installed and removed, making them suitable for temporary rail lines that need to be set up and dismantled quickly.

- Q:Can steel rails be used in railway sidings?

- Yes, steel rails can be used in railway sidings.

- Q:What are the factors to consider when designing steel rails for heavy-duty freight trains?

- When designing steel rails for heavy-duty freight trains, several factors need to be considered. These include the weight and load capacity of the trains, the speed and frequency of the trains, the type of freight being transported, the topography and geotechnical conditions of the rail bed, and the expected service life of the rails. Additionally, factors such as track alignment, track geometry, rail profile, and maintenance requirements should also be taken into account to ensure safe and efficient operations.

- Q:Are steel rails used in railway signaling gantries?

- Yes, steel rails are commonly used in railway signaling gantries.

- Q:How are steel rails protected against graffiti or vandalism?

- Steel rails are typically protected against graffiti or vandalism through a process known as anti-graffiti coating. This coating is applied to the surface of the rail, forming a protective layer that makes it easier to remove graffiti or prevent it from adhering to the steel. Additionally, some rail companies may also employ surveillance systems or security personnel to deter vandalism and quickly address any incidents.

- Q:How are steel rails affected by changes in train axle loads?

- Steel rails are affected by changes in train axle loads in terms of wear and deformation. Higher axle loads increase the stress and strain on the rails, leading to faster wear and potential deformation. This can ultimately result in decreased rail lifespan and the need for more frequent maintenance and replacement.

- Q:Can steel rails be used in extreme weather conditions?

- Yes, steel rails can be used in extreme weather conditions. Steel is a durable material that can withstand various weather conditions, including extreme heat, cold, and humidity. Additionally, steel rails are designed to expand and contract without losing their structural integrity, which makes them suitable for extreme weather conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Light Steel Rail with High Quality 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords