high quality steel light rail

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

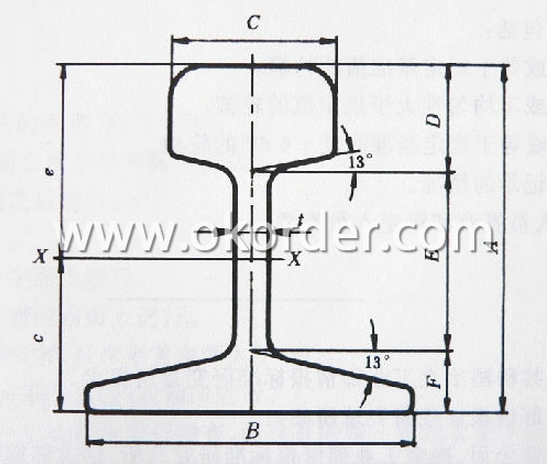

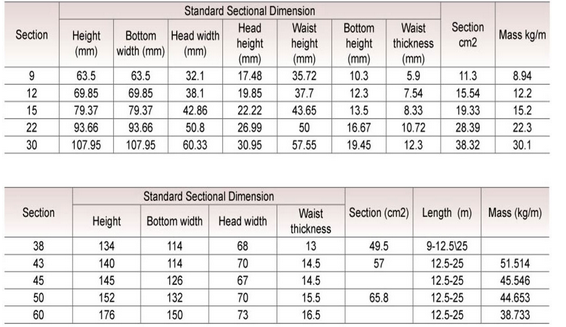

Specifications of Ms Steel Rail

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Grade: 55Q

Sizes: 9kg-60kg

Length: 6M-25M as the requriement of the clients

Applications of Ms Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of Ms Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms:30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

8. Others: Invoicing on theoretical weight or actual weight as customer request

Inspection of Ms Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: How do steel rails contribute to reducing train delays and disruptions?

- Steel rails contribute to reducing train delays and disruptions by providing a reliable and durable track infrastructure. The strength and stability of steel rails ensure smooth and efficient movement of trains, minimizing the risk of track deformations, derailments, and accidents. Furthermore, steel rails have a longer lifespan and require less maintenance compared to other materials, reducing the frequency of track repairs and thereby minimizing potential disruptions to train services.

- Q: How are steel rails protected against damage from debris or foreign objects?

- Steel rails are typically protected against damage from debris or foreign objects through the implementation of various measures such as regular inspections, maintenance, and the use of protective devices like track pans, rail sweeps, and deflectors. These measures help ensure that any debris or foreign objects are detected and cleared from the tracks to prevent potential damage to the steel rails.

- Q: How are steel rails protected against corrosion from environmental factors?

- Steel rails are protected against corrosion from environmental factors through a process called galvanization. This involves coating the rails with a layer of zinc, which acts as a sacrificial anode and prevents the steel from coming into direct contact with corrosive elements. Additionally, regular maintenance and inspection of the rails is carried out to identify and repair any damage or potential corrosion spots.

- Q: How are steel rails tested for strength?

- Steel rails are tested for strength through a process called rail fatigue testing. This involves subjecting the rails to repeated loading and unloading cycles to simulate the stress they experience during train operations. The rails are typically placed on a testing machine that applies varying loads and measures the resulting deflection and stress. By analyzing this data, engineers can determine the strength and durability of the steel rails.

- Q: What are the requirements for steel rail storage and handling?

- The requirements for steel rail storage and handling can vary depending on the specific circumstances and industry standards. However, there are some general requirements that are typically followed to ensure the safety and proper handling of steel rails. 1. Storage Space: Adequate storage space is required for steel rail storage. The area should be clear of any debris or obstructions and should have a solid, flat surface to prevent any bending or damage to the rails. The rails should be properly stacked with sufficient clearance between each layer to prevent any distortion or bending. 2. Environmental Conditions: Steel rails should be stored in a dry, well-ventilated area to protect them from moisture and humidity. Excessive exposure to moisture can lead to rust and corrosion, which can weaken the rails over time. It is also important to protect the rails from extreme temperatures and direct sunlight, as this can cause expansion or contraction and affect their structural integrity. 3. Handling Equipment: The use of appropriate handling equipment is essential to ensure the safe transportation and storage of steel rails. This may include cranes, forklifts, or railcar movers, depending on the size and weight of the rails. The equipment should be properly maintained and operated by trained personnel to prevent accidents and damage to the rails. 4. Handling Techniques: When handling steel rails, it is important to use proper lifting techniques to prevent any bending or distortion. The rails should be lifted evenly and supported throughout their length to avoid any stress concentration points. Additionally, sharp or pointed objects should be kept away from the rails to prevent scratching or gouging. 5. Marking and Identification: Each steel rail should be properly marked and identified to ensure traceability and easy identification. This may include markings such as the rail type, size, and manufacturer's information. Proper labeling and documentation are essential for inventory management and quality control purposes. 6. Inspection and Maintenance: Regular inspection and maintenance of steel rails are crucial to identify any signs of damage, wear, or corrosion. Any rails that do not meet the required standards or show signs of defect should be removed from service and replaced promptly. Overall, the requirements for steel rail storage and handling involve creating a safe and suitable environment, using proper equipment and techniques, and ensuring regular inspection and maintenance. Following these requirements helps to prolong the lifespan of the rails, maintain their structural integrity, and prevent accidents or damage during storage and transportation.

- Q: What are the safety requirements for steel rail construction?

- Safety requirements for steel rail construction are essential to ensure the well-being of workers and the public, as well as to prevent accidents and promote the overall integrity of the rail infrastructure. Some of the key safety requirements for steel rail construction include: 1. Personal Protective Equipment (PPE): Workers involved in steel rail construction must wear appropriate PPE, such as hard hats, safety glasses, high-visibility clothing, and steel-toed boots. This protects them from head injuries, flying debris, visibility issues, and potential foot injuries. 2. Training and Competency: All workers involved in steel rail construction should receive proper training and demonstrate competence in their respective tasks. This includes knowledge of safety procedures, equipment operation, and emergency response protocols. 3. Fall Protection: Workers who are required to work at heights, such as on elevated tracks or bridges, must have fall protection systems in place. This can include safety harnesses, guardrails, and safety nets to prevent falls and minimize the risk of injury or fatality. 4. Machinery and Equipment Safety: Construction equipment used in steel rail construction, such as cranes, excavators, and welding machines, should be regularly inspected, properly maintained, and operated by trained personnel. Safety devices, such as warning lights, alarms, and emergency stops, should be in place to prevent accidents. 5. Hazardous Materials Handling: Steel rail construction may involve the use of hazardous materials, such as welding gases or chemicals for corrosion protection. Proper storage, handling, and disposal procedures should be followed to minimize the risk of accidents, spills, and exposure to harmful substances. 6. Traffic Control: When working near existing rail lines or roadways, proper traffic control measures should be implemented to protect workers and the public. This may include signage, barricades, flaggers, or temporary traffic diversions to ensure safe movement of vehicles and pedestrians. 7. Environmental Considerations: Steel rail construction should adhere to environmental regulations and minimize the impact on surrounding ecosystems. Measures should be in place to prevent soil erosion, water pollution, and disturbance to wildlife habitats. 8. Emergency Preparedness: A comprehensive emergency response plan should be in place to address any accidents, injuries, or emergencies that may occur during steel rail construction. This plan should outline emergency procedures, communication protocols, and the availability of first aid and medical facilities on-site. By adhering to these safety requirements, steel rail construction projects can be carried out with minimal risks to workers, the public, and the environment, ensuring the longevity and reliability of the rail infrastructure.

- Q: What is the cost of steel rails?

- The cost of steel rails can vary depending on several factors such as the length, weight, quality, and market conditions. It is best to consult with suppliers or manufacturers to get accurate and up-to-date pricing information.

- Q: Are there any alternative materials to steel for railway tracks?

- Yes, there are alternative materials to steel for railway tracks. Some of these alternatives include concrete, composite materials, and plastic. These materials offer different advantages such as reduced maintenance, increased durability, and lighter weight. However, each alternative material has its own unique characteristics and considerations that need to be evaluated for specific railway track applications.

- Q: What are the different types of steel rail crossings for pedestrians?

- There are several different types of steel rail crossings for pedestrians, including level crossings, pedestrian overpasses, and underpasses.

- Q: Why can the single phase of catenary be used? Why is rail used as loop without electricity?

- In addition, there are different signals in different places, and the signals on the rails are differentThe most basic electrified railway, there is a track voltage between the two rails, in addition to the code, etc., and now there are a lot of station information is also sent to the locomotive by rail

Send your message to us

high quality steel light rail

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords