Ms Heavy Steel Rail 50Mn, U71Mn

- Loading Port:

- Qingdao Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

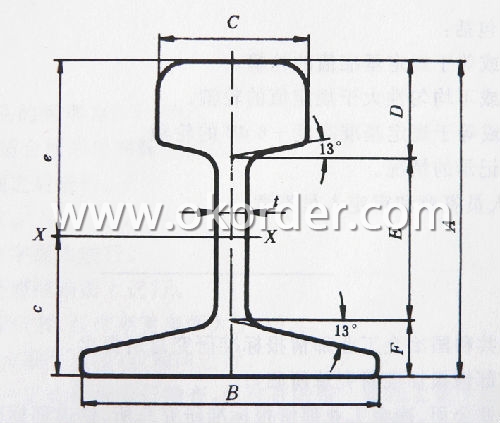

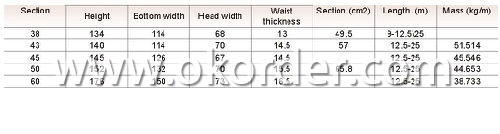

Specificaions of Ms Heavy Steel Rail 50Mn, U71Mn

Production Standard: GB2585-81

Material: 50Mn, U71Mn

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

50Mn |

0.48—0.56 |

0.70—1.00 |

≤0.035 |

≤0.035

|

0.17-0.37 |

U71Mn | 0.65—0.76 | 1.10—1.40 | ≤0.030 | ≤0.030 | 0.15-0.35 |

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Length: 10m, 12m, 12.5m or as the requriement of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usage & Applications of Ms Heavy Steel Rail 50Mn, U71Mn

Heavy Steel Rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel, can also be used for tower crane and other crane track.

For example: railway, subway, transportation track, express, curve way, tunnel way.

Packaging & Delivery of Ms Heavy Steel Rai 50Mn, U71Mn

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Ms Heavy Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Ms Heavy Steel Rail 50Mn, U71Mn

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Ms Heavy Steel Rail 50Mn, U71Mn

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: Are steel rails suitable for both freight and passenger rail systems?

- Yes, steel rails are suitable for both freight and passenger rail systems. Steel rails are highly durable and can withstand heavy loads, making them ideal for carrying freight trains. Additionally, they provide a smooth and stable surface, ensuring a comfortable and safe ride for passengers. Due to their strength and versatility, steel rails are widely used in both freight and passenger rail systems worldwide.

- Q: What are the specifications for steel rail vibration control?

- The specifications for steel rail vibration control typically include factors such as the rail profile, rail material, rail fastening system, rail support structure, and the desired level of vibration reduction. These specifications may vary depending on the specific application and the level of vibration control required.

- Q: Can steel rails be used in areas with high levels of noise pollution?

- Indeed, steel rails are fitting for areas with high levels of noise pollution. They are widely utilized in railway tracks due to their numerous favorable attributes. Firstly, steel rails possess exceptional durability and strength, enabling them to withstand substantial loads and frequent train traffic. This durability aids in minimizing the noise produced by train movements. Furthermore, steel rails can be designed with specific characteristics that help diminish noise pollution. For example, rails can be equipped with noise-dampening materials or specialized rail pads that absorb vibrations and reduce the transmission of noise to the surrounding environment. These measures substantially decrease the noise levels generated by train operations. Additionally, steel rails can be combined with other noise-reducing measures such as sound barriers or noise barriers positioned alongside the tracks. These barriers effectively obstruct or redirect sound waves, further diminishing the impact of noise pollution on the nearby areas. However, it is important to acknowledge that although steel rails contribute to noise mitigation, they may not completely eradicate it. Noise pollution is a multifaceted issue influenced by various factors including train speed, train types, maintenance practices, and surrounding infrastructure. Therefore, a comprehensive approach that integrates noise reduction measures at multiple levels is often necessary to effectively address noise pollution in areas with high train activity.

- Q: What are the environmental benefits of using steel rails over other materials?

- There are several environmental benefits of using steel rails over other materials in various applications, particularly in the transportation sector. Firstly, steel is a highly durable material that has a long lifespan. This means that steel rails require less maintenance and replacement, reducing the need for frequent material production and transportation. This longevity of steel rails helps minimize the overall environmental impact associated with their manufacturing and disposal. Secondly, steel is a recyclable material. At the end of their life cycle, steel rails can be easily recycled and used to produce new steel products. This reduces the demand for virgin materials, conserves natural resources, and decreases the energy and emissions associated with primary steel production. Additionally, steel rails have a lower carbon footprint compared to other materials. Steel manufacturing processes have significantly improved over the years, leading to reduced energy consumption and greenhouse gas emissions. This makes steel rails a more sustainable option for rail infrastructure, contributing to lower environmental impact over their lifespan. Moreover, steel rails offer excellent load-bearing capacity, allowing for heavier and longer trains. This means that more goods can be transported in a single trip, resulting in fewer trips and reduced fuel consumption. With less fuel burned, the emissions of greenhouse gases and other harmful pollutants are reduced, helping to mitigate air pollution and climate change. Lastly, the use of steel rails promotes the shift towards more sustainable modes of transportation. Rail transportation is generally considered more energy-efficient and environmentally friendly compared to road or air transport. By using steel rails, we can encourage the growth of rail networks, which can help reduce congestion, lower fuel consumption, and decrease the overall environmental impact of transportation systems. In summary, the environmental benefits of using steel rails over other materials are related to their durability, recyclability, lower carbon footprint, load-bearing capacity, and their contribution to a more sustainable transportation sector. By choosing steel rails, we can reduce waste, conserve resources, and minimize environmental impacts, making it an environmentally responsible choice for rail infrastructure.

- Q: What are the safety regulations for steel rail installation?

- To prevent accidents and ensure the safety of railway workers and the public, safety regulations have been established for the installation of steel rails. These regulations include: 1. Site Inspection: Prior to installation, a thorough examination of the site must be conducted to identify any potential hazards or obstacles that could impact the installation process. This includes assessing the terrain, soil conditions, and nearby structures or utilities. 2. Proper Equipment: It is crucial to utilize appropriate equipment to maintain safety during rail installation. This includes regularly inspecting specialized machinery such as cranes, track tamping machines, and rail fastening systems to ensure their proper functioning. 3. Personal Protective Equipment (PPE): All workers involved in rail installation must wear the necessary PPE, including hard hats, safety glasses, high-visibility clothing, steel-toed boots, and gloves. This is to protect them from potential dangers like falling objects, flying debris, or accidental contact with machinery. 4. Training and Certification: Workers engaged in steel rail installation should undergo comprehensive training on safety procedures and be certified to operate specific equipment. Regular refresher courses should also be provided to ensure adherence to the latest safety protocols. 5. Traffic Management: When installing steel rails near roadways or pedestrian areas, appropriate traffic management measures must be implemented to redirect or control traffic flow, ensuring the safety of workers and the public. This may involve using barriers, warning signs, and flaggers. 6. Communication and Coordination: Effective communication and coordination among all parties involved in the rail installation project are crucial for ensuring safety. This includes regular meetings, clear instructions, and the use of radios or other communication devices to relay important information. 7. Quality Control: Regular inspections and testing should be carried out on the installed steel rails to verify compliance with required standards and secure fastening. This includes checking for defects, proper alignment, and sufficient stability to prevent derailments or accidents. It is important to note that safety regulations for steel rail installation may differ based on the country, region, or specific railway authority. Therefore, it is essential to consult the relevant local regulations and guidelines to ensure compliance with specific safety requirements in a particular jurisdiction.

- Q: Why can't the vertical rail bend the rail?

- In order to solve this problem, the railway department within a certain distance, playing a few holes in the rail waist to release the energy generated by thermal expansion and contraction, and within a certain distance (about 1500m) retaining rail joint, to assist in releasing the energy generated by the thermal expansion and contraction, in order to solve the problem of rail expansion and contraction.

- Q: How are steel rails repaired in case of damage?

- In case of damage, a series of steps are followed to repair steel rails. The initial step involves identifying the section of the rail that has been damaged. This is typically accomplished through regular inspections or by monitoring the rail for any signs of wear or damage. Once the damaged section has been identified, the rail is usually isolated from train traffic to guarantee safety during the repair process. The subsequent step entails removing the damaged portion of the rail. This can be achieved by utilizing specialized tools to cut out the damaged section or by employing a technique known as grinding, which involves eliminating any defects by removing a thin layer of the rail. The removed section is then either discarded or sent for recycling. After the damaged section has been removed, a replacement rail section is prepared for installation. This involves measuring and cutting the replacement rail to the necessary length and ensuring that it meets the specifications of the existing rail. Subsequently, the replacement rail is positioned and aligned with the adjacent rails to ensure a seamless connection. To secure the replacement rail in place, various methods can be utilized. One commonly used method is to employ rail fasteners, such as clips or bolts, to securely hold the rail to the track bed. These fasteners aid in maintaining proper alignment and prevent any movement or shifting of the rail during train operations. Once the replacement rail has been secured, the final step involves conducting a series of tests to verify the success of the repair. These tests typically encompass checking the alignment of the rail, measuring the gauge (distance between the rails), and inspecting for any potential issues that may impact train safety. In summary, the repair process for steel rails involves the identification of the damaged section, removal of the damaged portion, preparation and installation of a replacement rail, securing of the replacement rail, and conducting tests to ensure the success of the repair. This process guarantees the safety and functionality of the rail line, enabling uninterrupted train operations.

- Q: What are the dimensions of steel rails?

- The dimensions of steel rails vary depending on the specific application and standard being followed. However, commonly used dimensions for standard railroad tracks include a length of 39 feet and a weight per yard of 115 pounds.

- Q: What is the working principle of a rail profilometer?

- Rail profilometer with a stylus instrument and the measured surface slip measurement, direct measurement of the rail surface, such as surface roughness, hole slot, according to certain standard readings or directly depict the surface contour shape, measuring speed, reliable and convenient operation. The tested surface is easy to be scratched by the contact pin, and the measuring pressure is minimized as long as the reliable contact is ensured, and the accuracy is ensured by the high precision device, such as hydraulic pressure or air floating guide rail.

- Q: Discontinuous rail seamless rail effect

- The rail welding seamless rail is 25 meters long up into several hundred meters or even thousands of meters long, and then put on the roadbed, seamless rail gap of 11 mm between each segment. Seamless rail is seamed, will also be affected.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ms Heavy Steel Rail 50Mn, U71Mn

- Loading Port:

- Qingdao Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords