Ms Steel Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Ms Steel Rail

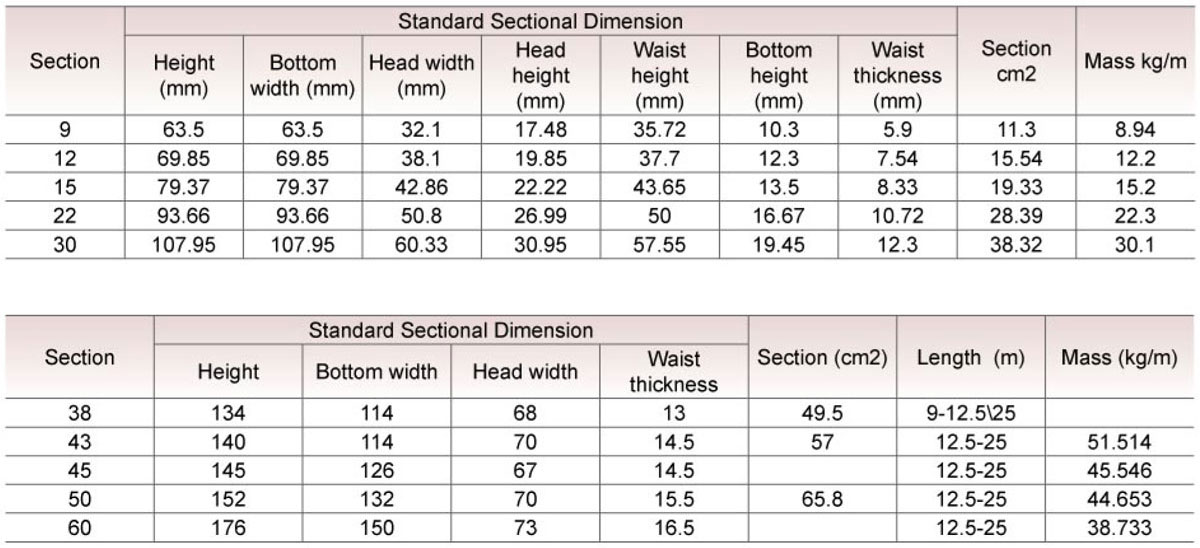

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Grade: Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260, etc.

Sizes: 9kg-60kg

Length: 6M-25M as the requriement of the clients

Applications of Ms Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of Ms Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms:30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

8. Others: Invoicing on theoretical weight or actual weight as customer request

Inspection of Ms Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: What is the average lifespan of a steel rail in a subway system?

- The average lifespan of a steel rail in a subway system can differ based on several factors, including the type of rail, the intensity of subway system usage, maintenance practices, and environmental conditions. Typically, steel rails in subway systems are built to endure for 25 to 50 years. Nevertheless, certain steel rails have been documented to surpass this lifespan thanks to appropriate maintenance and regular inspections. It should be emphasized that regular maintenance, such as grinding and replacing worn rails, is crucial for guaranteeing the endurance and safety of the rail infrastructure in a subway system.

- Q: How much do steel rails weigh?

- The weight of steel rails can vary depending on their size and type. Generally, a standard steel rail used in railway tracks weighs around 50 kilograms (110 pounds) per meter. However, this weight can vary slightly depending on factors such as the rail profile, grade, and manufacturer specifications. It is important to note that longer rails, such as those used in high-speed rail lines, can weigh significantly more due to their increased length.

- Q: Can steel rails be used for tram systems?

- Yes, steel rails can be used for tram systems. Steel is a commonly used material for tram tracks due to its durability, strength, and resistance to wear and tear. It provides a stable and smooth surface for trams to travel on, ensuring safe and efficient operations.

- Q: How are steel rails protected from rust?

- Corrosion protection is employed to safeguard steel rails against rust. To ensure their longevity, various methods are employed. One commonly used approach involves the application of a protective coating. This entails covering the surface of the steel rails with paint or a specialized coating. The purpose of this coating is to create a barrier between the steel and its environment. By doing so, it prevents moisture, oxygen, and other corrosive elements from reaching the metal surface and causing rust. Furthermore, this coating provides defense against corrosive substances like chemicals or pollutants. Another method employed for rust protection is galvanization. This technique involves applying a layer of zinc to the surface of the steel rails. Not only does this process prevent rust formation, but it also enhances the steel's durability. Consequently, galvanized steel rails are commonly used in outdoor environments or areas with high levels of moisture due to their superior resistance to corrosion. Regular maintenance and inspection are also vital to protect steel rails from rust. Prompt action should be taken if any damage to the protective coating or galvanized layer is detected. This may involve recoating the affected areas or applying a corrosion inhibitor to prevent further rusting. In conclusion, the protection of steel rails from rust involves the use of protective coatings, galvanization, and regular maintenance. These measures ensure that the rails can endure the harsh conditions they are exposed to, maintaining their structural integrity over time.

- Q: How do steel rails handle different train lengths?

- Trains of varying lengths can be handled by steel rails, which are designed for this purpose. The length of a train directly affects the forces exerted on the rails during operation. Longer trains typically exert greater forces due to their higher weight and momentum. However, steel rails are engineered to withstand these forces and distribute the loads effectively. Steel rails handle different train lengths in multiple ways. Firstly, they possess inherent strength and durability. Steel is a robust material that can bear heavy loads without deforming or breaking. The rails are manufactured with specific dimensions and thicknesses to meet the requirements of various train lengths. This ensures that the rails remain intact and can safely support the weight of the trains. Furthermore, the design and construction of rail tracks take into account the dynamic forces generated by different train lengths. The rails are laid on a stable base, such as ballast or concrete, which helps absorb and distribute the forces exerted by the trains. The track structure, including the sleepers and fastenings, is designed to provide stability and prevent excessive movement or deformation under varying loads. Moreover, rail operators implement advanced track maintenance and inspection practices to ensure the rails are in optimal condition to handle different train lengths. Regular inspections, track alignments, and maintenance activities are carried out to identify any potential issues and prevent rail failures. These measures help maintain the integrity of the steel rails and ensure their ability to handle trains of varying lengths. In conclusion, steel rails are specifically designed and constructed to handle trains of different lengths. Their inherent strength, along with proper track design and maintenance practices, enables them to effectively support and distribute the forces exerted by trains of varying sizes.

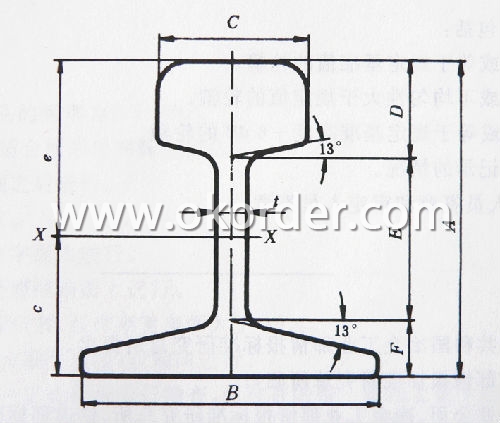

- Q: What are the main components of a steel rail?

- The main components of a steel rail are the head, web, and base. The head is the top part of the rail that comes into contact with train wheels, while the web connects the head to the base. The base, on the other hand, provides stability and support to the rail. These components work together to ensure the safe and efficient operation of trains on railway tracks.

- Q: How are steel rails protected against excessive heat?

- Steel rails are protected against excessive heat by using various methods such as employing heat-resistant materials, implementing cooling systems, and ensuring proper ventilation.

- Q: Cause analysis of manganese stiffness in rail

- In the manufacture of rail, in addition to adding more manganese, in the upper rail, the layer and is contacted with a wheel, but also added another kind of metal, indium, it added to the rail on the part of the hardness of the case, even has some toughness, the train wheel is very important it is time, and the "tire" contact, collision, there will be some flexibility, to ensure the safe operation of the train.

- Q: How do steel rails handle train braking forces?

- Steel rails are specifically designed to handle the immense braking forces exerted by trains. The high tensile strength and durability of steel make it capable of withstanding the tremendous pressure and friction generated during braking. The rails' sturdy construction allows them to effectively distribute and dissipate these forces, ensuring safe and reliable train operations.

- Q: How do steel rails contribute to reducing train fuel consumption?

- Steel rails contribute to reducing train fuel consumption in several ways. Firstly, steel rails provide a smooth and durable surface for train wheels to roll on, resulting in reduced friction and less energy required to propel the train forward. This efficiency allows trains to travel at higher speeds while consuming less fuel. Additionally, steel rails offer better stability and support, reducing the need for excessive braking and accelerating, which further minimizes fuel consumption. Overall, steel rails play a crucial role in improving the overall energy efficiency and performance of trains, ultimately reducing fuel consumption.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ms Steel Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords