Steel Heavy Rail with High Quality for Structure Project and Building

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

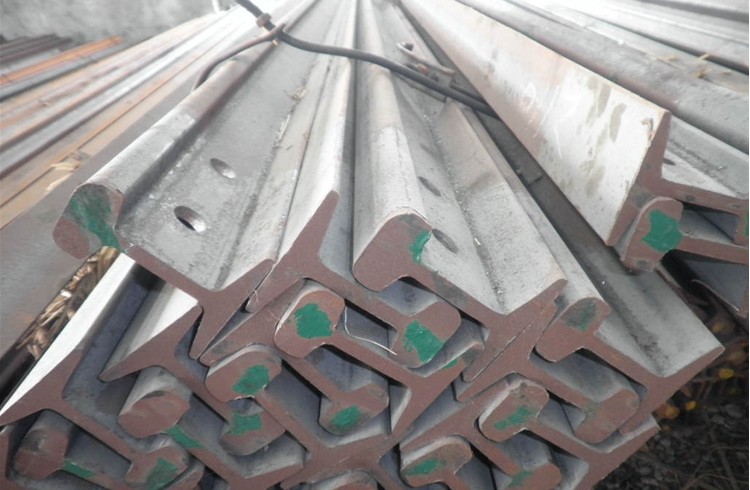

Product Description of Steel Heavy Rail with High Quality for Structure Project and Building:

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Usages of Steel Heavy Rail with High Quality for Structure Project and Building:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Steel Heavy Rail with High Quality for Structure Project and Building:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Steel Heavy Rail with High Quality for Structure Project and Building:

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Why buy Materials & Equipment from OKorder.com?

A3: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Images:

- Q: Are steel rails suitable for both freight and passenger rail systems?

- Steel rails are suitable for both freight and passenger rail systems, providing durability and strength to withstand heavy loads and ensure track stability. With a proven track record spanning decades, steel has been widely used in railway infrastructure worldwide, proving highly effective for both rail systems. In the case of freight rail systems, steel rails are indispensable due to their ability to handle the weight and pressure exerted by heavy cargo trains. These trains transport large quantities of goods, including heavy machinery, raw materials, and containers. Steel rails are specifically designed to bear this weight and offer a smooth and stable surface for the trains to traverse. Furthermore, they are resistant to wear and tear caused by the constant movement of heavy freight trains, making them a reliable choice for freight rail systems. Similarly, steel rails are equally suitable for passenger rail systems. While passenger trains may not be as heavy as freight trains, they still require a robust and dependable track system. Steel rails ensure a safe and comfortable ride for passengers, prioritizing their comfort and safety throughout the journey. Additionally, steel rails are compatible with high-speed trains, facilitating efficient and rapid transportation of passengers. In summary, steel rails are an excellent option for both freight and passenger rail systems, offering durability, strength, and wear resistance. They serve as a reliable and long-lasting foundation for efficient and secure rail operations, whether it involves transporting goods or people.

- Q: How do steel rails affect train ride comfort?

- Steel rails play a crucial role in ensuring a smooth and comfortable train ride. The strength and durability of steel allow for the tracks to remain stable, reducing vibrations and jolts experienced by passengers. Additionally, steel rails are designed to provide a consistent and level surface, minimizing bumps and disturbances, thereby enhancing the overall comfort of the train ride.

- Q: What are the different types of rail maintenance vehicles used with steel rails?

- There are several types of rail maintenance vehicles used with steel rails. Some common ones include rail grinders, which are used to remove imperfections and restore the shape of the steel rails; rail trucks, which are equipped with tools and equipment for various maintenance tasks such as track inspection, welding, and fastening; rail cranes, used for heavy lifting and construction projects; and ballast regulators, which distribute and shape the ballast material under the tracks to maintain stability. These vehicles play a crucial role in ensuring the safety and efficiency of railway systems.

- Q: Can steel rails be replaced without disrupting train services?

- Yes, steel rails can be replaced without disrupting train services. This can be achieved by carefully planning and scheduling the maintenance work during periods of low train traffic, such as overnight or during weekends. Additionally, temporary tracks or bypasses can be installed to ensure trains can continue to run smoothly while the replacement work is being carried out.

- Q: How do steel rails contribute to the stability of a train?

- Steel rails contribute to the stability of a train by providing a sturdy and smooth surface for the train to travel on. The steel rails are laid in a precise alignment, ensuring that the wheels of the train stay on track and prevent any derailment. Additionally, the weight of the train is evenly distributed along the rails, reducing the chances of tilting or tipping over. The steel rails also absorb and disperse the vibrations and impact forces generated by the moving train, enhancing the overall stability and safety of the train.

- Q: What are the potential risks of using steel rails in extreme weather conditions?

- The potential risks of using steel rails in extreme weather conditions include expansion and contraction due to temperature changes, which can lead to track buckling or warping. Additionally, heavy rain or snow can cause the rails to become slippery, increasing the risk of train derailments. Moreover, extreme cold can make the steel rails brittle, increasing the likelihood of cracks or fractures. Overall, these factors may compromise the safety and stability of the railway system during severe weather conditions.

- Q: How do steel rails contribute to the overall smoothness of train travel?

- Several key factors contribute to the overall smoothness of train travel provided by steel rails. Firstly, the stable and durable surface they offer allows trains to run smoothly. The consistency of the steel rails ensures that the wheels of the train maintain uninterrupted contact with the track, resulting in a ride that is free of interruptions. Additionally, the high level of strength and resistance to deformation exhibited by steel rails allows them to withstand the heavy weight of the train and distribute the load evenly. This even distribution of weight prevents any unevenness or bumps along the track, reducing vibrations and shocks and ultimately making the journey smoother and more comfortable for passengers. Moreover, steel rails are meticulously designed to maintain their shape over long distances and to be precisely aligned. This precise alignment ensures that the wheels of the train follow a consistent path, minimizing any lateral movement or swaying. Such absence of lateral movement contributes to a smoother ride and helps to minimize any jostling or side-to-side motion experienced by passengers. Furthermore, steel rails undergo regular maintenance and inspection to ensure their smoothness. Any defects or irregularities, such as cracks or wear, are promptly identified and repaired. This maintenance work helps to uphold the smoothness of the rails and prevent any potential disruptions or discomfort during train travel. In conclusion, steel rails are essential in providing a smooth and comfortable train travel experience. Their stability, strength, alignment, and regular maintenance all contribute to minimizing vibrations, shocks, and lateral movement, resulting in a ride that is consistently smooth for passengers.

- Q: How are steel rails protected from expansion joint failures?

- Steel rails are protected from expansion joint failures through a variety of measures. One of the key methods is the use of specially designed expansion joints that are able to accommodate the expansion and contraction of the rails due to temperature changes. These expansion joints are typically made of materials that are resistant to wear and tear, such as elastomers or steel. In addition to using suitable expansion joints, regular maintenance and inspections are conducted to identify any potential issues or failures. This includes checking for any signs of wear, corrosion, or damage to the expansion joints. Any damaged or worn-out expansion joints are promptly replaced to ensure the integrity of the rail system. Furthermore, proper installation techniques are crucial to prevent expansion joint failures. The joints need to be installed correctly, with sufficient clearance and proper alignment, to allow for the necessary movement of the rails. This ensures that the expansion joints can effectively absorb the expansion and contraction forces without causing failures. Another important aspect of protecting steel rails from expansion joint failures is ensuring proper drainage. Adequate drainage systems are implemented to prevent water accumulation around the expansion joints, as water can accelerate corrosion and deterioration of the joints. Regular cleaning and maintenance of these drainage systems are also essential to keep them functioning effectively. Overall, the protection of steel rails from expansion joint failures involves a combination of using suitable expansion joints, conducting regular maintenance and inspections, ensuring proper installation, and implementing effective drainage systems. By implementing these measures, the risk of expansion joint failures is minimized, ensuring the safe and reliable operation of the rail system.

- Q: What are the benefits of using steel rails over other materials?

- There are several benefits of using steel rails over other materials. Firstly, steel is incredibly strong and durable, making it resistant to wear and tear caused by heavy loads and constant use. This ensures a longer lifespan for the rail tracks, reducing maintenance and replacement costs. Secondly, steel rails offer excellent stability and support, enabling trains to travel at high speeds safely and smoothly. Additionally, steel is highly resistant to extreme weather conditions, such as heat, cold, and moisture, which helps prevent damage and ensures reliable performance. Finally, steel is a recyclable material, making it an environmentally friendly choice for rail infrastructure as it can be reused or repurposed at the end of its life cycle.

- Q: How much do steel rails cost?

- The cost of steel rails can vary depending on various factors such as the grade of steel, length of the rails, market conditions, and the quantity being purchased. It is recommended to contact steel suppliers or conduct market research to obtain accurate pricing information.

Send your message to us

Steel Heavy Rail with High Quality for Structure Project and Building

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches