Ms Light Steel Rail Q235, 55Q

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Ms Light Steel Rail Q235, 55Q

Production Standard: GB11264-89

Material: Q235, 55Q

Grade | Element(%) | ||||

C | Mn | S

| P

| Si

| |

Q235 |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

55Q | 0.50—0.60 | 0.70—1.00 | ≤0.050 | ≤0.045 | 0.15-0.35 |

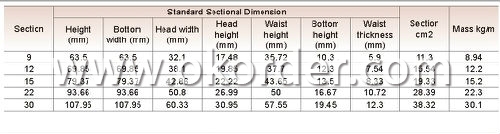

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6M, 8M, 10M, 12M or as the requriement

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Ms Light Steel Rail Q235, 55Q

Light Steel Rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line, for example:

railway, subway, transportation track, express, curve way, tunnel way.

Package & Delivery of Ms Light Steel Rail Q235, 55Q

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Ms Light Steel Rail Q235, 55Q

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Ms Light Steel Rail Q235, 55Q

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:How do steel rails handle heavy loads and freight trains?

- Steel rails are able to handle heavy loads and freight trains due to their high strength and durability. The steel used in rail construction is specifically designed to withstand immense weight and pressure. Additionally, the rails are carefully laid and securely fastened to ensure stability and minimize any potential damage. This allows steel rails to effectively support and guide heavy loads, ensuring safe and efficient transportation for freight trains.

- Q:What are the maintenance requirements for steel rails in urban areas?

- The maintenance requirements for steel rails in urban areas include regular inspections to identify any defects or damage, cleaning to remove debris and prevent corrosion, lubrication to reduce friction and wear, and occasional repairs or replacements of worn-out sections. Additionally, measures to prevent excessive noise and vibration, such as track dampening systems, may also be necessary in densely populated areas.

- Q:How do steel rails contribute to the reduction of accidents in rail transportation?

- Steel rails contribute to the reduction of accidents in rail transportation in several ways. First, steel is a durable and strong material that provides a stable and reliable track system, minimizing the risk of derailments and collisions. Additionally, steel rails are designed to withstand heavy loads and extreme weather conditions, ensuring safe and smooth operation of trains. Furthermore, the low friction coefficient of steel rails allows for better control and braking, reducing the likelihood of accidents caused by excessive speed or sudden stops. Overall, the use of steel rails in rail transportation plays a crucial role in enhancing safety and preventing accidents.

- Q:How do steel rails contribute to the efficiency of railway systems?

- There are several ways in which steel rails contribute to the efficiency of railway systems. Firstly, steel is a very strong and durable material, allowing the rails to withstand heavy loads and constant wear and tear. This means that they can last for many years without requiring frequent replacement or repair, reducing maintenance costs and downtime. Secondly, the design of steel rails ensures that trains have a smooth and stable surface to travel on. The evenness of the rails helps to minimize vibrations and reduce friction between the wheels and the track, resulting in less energy being needed to propel the train forward. This not only improves the overall energy efficiency of the railway system but also enables trains to reach higher speeds, reducing travel times and increasing capacity. Additionally, steel rails are engineered with precise dimensions and alignment, ensuring safe and smooth travel for trains. This accuracy helps to prevent derailments and maintain train stability, enhancing the overall safety and reliability of the railway system. Moreover, steel rails are compatible with various signaling and control systems, allowing for efficient and precise train operation. These systems rely on the accurate positioning of trains on the tracks, which is facilitated by the consistent and well-maintained steel rails. Lastly, steel rails offer excellent resistance to corrosion, which is particularly important in areas with harsh weather conditions or exposure to moisture. The durability and resistance to corrosion of steel rails greatly reduce the need for frequent replacements, resulting in cost savings and improved efficiency for railway systems. In conclusion, steel rails play a crucial role in enhancing the efficiency of railway systems through their strength, durability, smoothness, precision, and resistance to corrosion. Their numerous advantages contribute to safer, faster, and more reliable train travel, ultimately improving the overall performance and effectiveness of railway systems.

- Q:What are the environmental benefits of using steel rails?

- There are several environmental benefits of using steel rails. Firstly, steel is a highly sustainable material as it can be recycled repeatedly without losing its strength. This reduces the need for new steel production, saving energy and reducing greenhouse gas emissions. Additionally, steel rails have a long lifespan and require minimal maintenance, which reduces waste generation and the need for frequent replacements. Moreover, railways powered by electricity produce significantly lower emissions compared to other forms of transportation, contributing to improved air quality and reduced carbon footprint.

- Q:Are steel rails affected by earthquakes or other natural disasters?

- Yes, steel rails can be affected by earthquakes or other natural disasters. These events can cause ground shaking, which may lead to rail displacement, misalignment, or even complete destruction. It is important to assess and repair any damages to ensure the safety and functionality of the railway infrastructure.

- Q:What are the factors to consider when selecting steel rails for a specific application?

- When selecting steel rails for a specific application, several factors need to be considered, including the required load capacity, the anticipated traffic volume, the environmental conditions, the desired lifespan, the compatibility with other components of the track system, and the cost-effectiveness of the rails. Additionally, factors such as the type of rail profile, the rail grade, and any specific requirements or regulations for the application should also be taken into account.

- Q:How do steel rails contribute to reducing train fuel consumption?

- Steel rails contribute to reducing train fuel consumption in several ways. Firstly, steel rails provide a smooth and durable surface for train wheels to roll on, resulting in reduced friction and less energy required to propel the train forward. This efficiency allows trains to travel at higher speeds while consuming less fuel. Additionally, steel rails offer better stability and support, reducing the need for excessive braking and accelerating, which further minimizes fuel consumption. Overall, steel rails play a crucial role in improving the overall energy efficiency and performance of trains, ultimately reducing fuel consumption.

- Q:How do steel rails support heavy loads?

- Steel rails support heavy loads through a combination of their strength, durability, and design. Firstly, steel is an incredibly strong material that can withstand significant amounts of force without bending or breaking. This strength allows steel rails to bear the weight of heavy loads without collapsing or deforming. Additionally, steel rails are designed to distribute the weight of the load evenly along their length. The rail profile, which consists of a flat bottom and a rounded top, helps to spread the load over a larger surface area, reducing the concentration of force at any particular point. This design feature prevents the rails from sinking into the ground or becoming damaged under heavy loads. Moreover, steel rails are often supported by sleepers or ties, which are placed at regular intervals along the track. These sleepers provide additional support and help to distribute the load evenly across the rail network. They also help to absorb vibrations and impact forces, further enhancing the rail's ability to support heavy loads. Furthermore, the rail's continuous welded construction ensures that there are no weak points or joints along its length, making it more resistant to fatigue and wear. This durability allows the steel rails to withstand repeated heavy loads over an extended period without significant deformation or damage. In summary, steel rails support heavy loads through their inherent strength, the design of their profile, the support provided by sleepers, and their durability. These factors combined enable steel rails to bear the weight of heavy loads and provide a stable and reliable transportation infrastructure for various industries.

- Q:Are steel rails used in railway maintenance vehicles?

- Railway maintenance vehicles commonly use steel rails. These vehicles have a specific design for fixing and maintaining railway tracks. Steel rails are the preferred material for railway infrastructure because of their durability, strength, and resistance to wear. To ensure smooth and efficient maintenance operations, railway maintenance vehicles like rail grinders, track tampers, and ballast regulators are equipped with steel rails. These vehicles rely on the stability and security provided by the steel rails as they perform tasks such as grinding, leveling, and packing the ballast. In summary, steel rails are essential for the proper functioning of railway maintenance vehicles, contributing to the safety and efficiency of railway transportation systems.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ms Light Steel Rail Q235, 55Q

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords