Hp 450 Graphite Electrodes RP HP UHP for Steelmaking Electric Arc Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

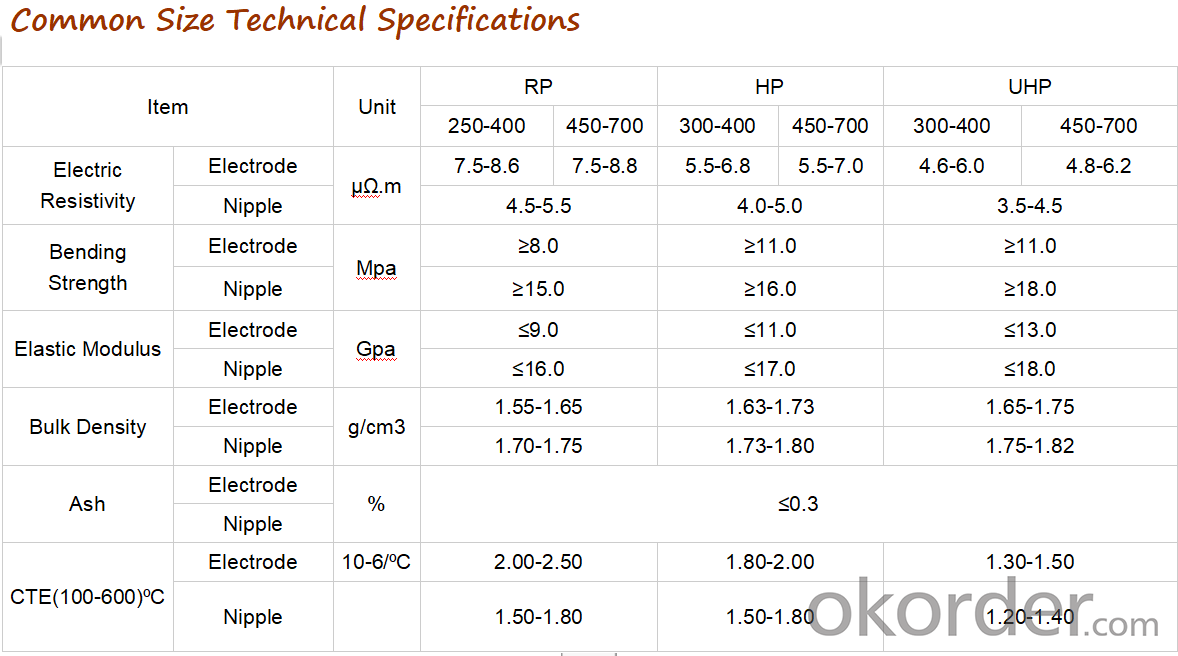

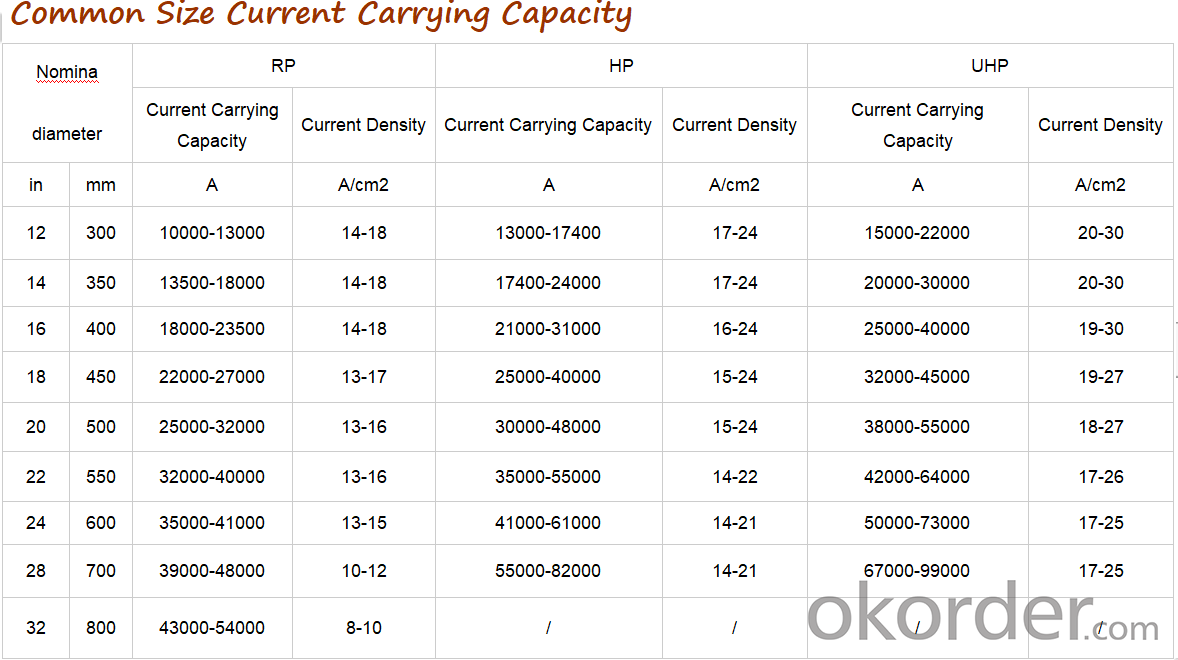

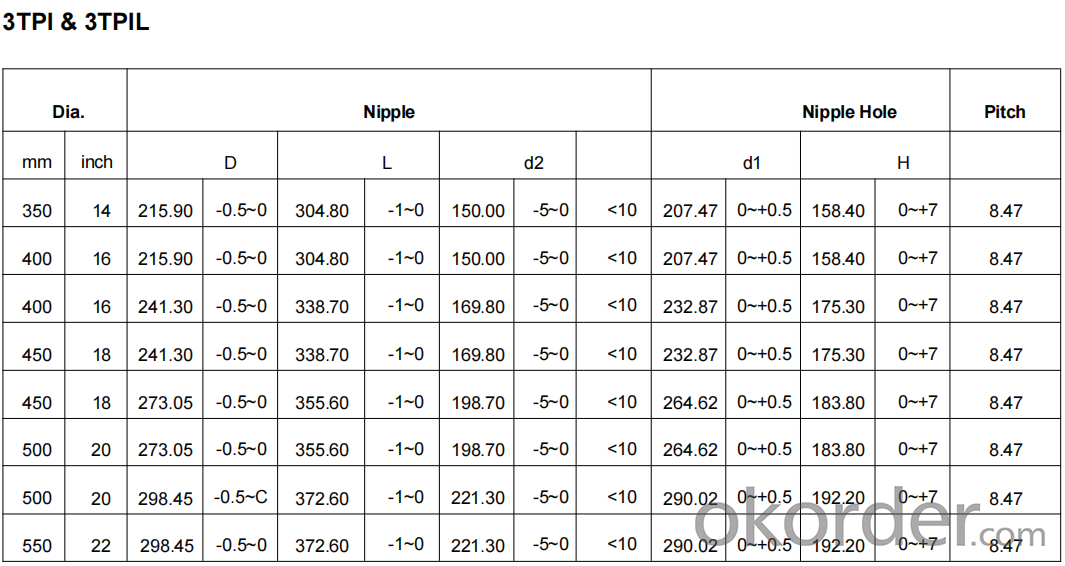

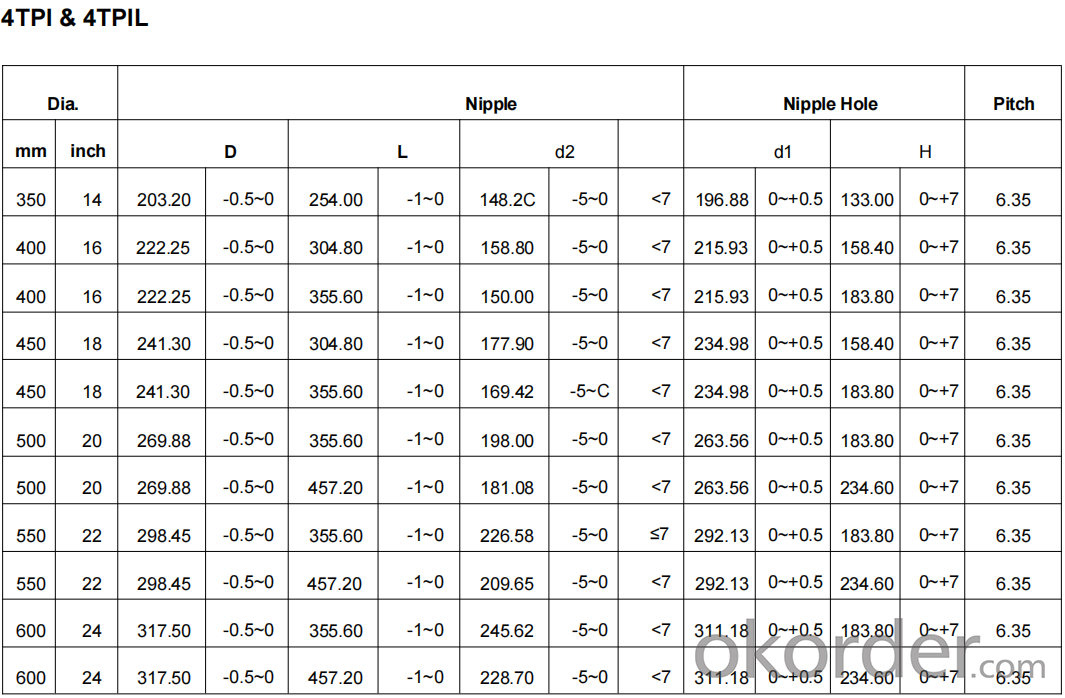

Specification

Graphite Electrode

Product range:

•RP: 200-700mm

•HP: 200-750mm

•SHP: 200-750mm

•UHP: 350-750mm

Quality control:

•Raw material:

Needle coke from world famous brand like Mitsubishi, Mizushima, Phillips 66 etc. and Chinese Tier-One manufacturers.

•During Production:

1.Visual automatic batching control room, 10 sets of high-precision machining equipment,

and an investment of 70 million on-line dust removal and environmental protection equipment,

exhaust gas recycle equipment.

2.High dimensional accuracy of nipples and threads.

3.Professional technical team with decades of experiences.

4.Before shipment, each electrode is inspected, test report will be made and has traceability mechanism.

•Logistics: High-standard shipping packaging to prevent bumps, take photos/videos for file.

•After-sales:

If there are quality problems with our products, we will replace them or solve them on-site according to the situation.

Please consult us for details of other dimensions.

Please consult us for details of other data.

Please consult us for details of other data.

- Q: Thermal expansion coefficient of graphite

- In the graphite electrode, the national standard, the volume density in more than 1.60 of both high power graphite electrode, of course because of the national standard index is low now, the volume density of normal power graphite electrode factory can reach 1.65, such as Chengde and long carbon factory.

- Q: Why use platinum ferroalloy instead of iron as electrode?

- Silica (Silica) is widely used in paint, ink, plastic, rubber and cosmetics, are often added to increase the performance of silica, such as oil absorption, extinction, strengthen the mechanical... Etc., and can reduce the cost of...

- Q: How to solve the problem of graphite electrode being crushed during electrolysis

- There's no way. It's an industrial problem, and that's how graphite works.

- Q: Why should the carbon brush for the trolley be made of graphite?

- Graphite conducts electricity and is self lubricant, resistant to wear. As for why, high school chemistry textbooks have ah.

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The high purity graphite component is put into the furnace, and nitrogen and methane are produced under vacuum high temperature. Then graphite is shown to produce 10% coating.

- Q: Graphite powder produced by graphite electrode and what we usually call graphite is a kind of thing?

- Graphite electrode is mainly in petroleum coke, coke as raw material

- Q: The graphite electrode made by the machining center adopts cooling method, which is water cooled, oil cooled and blow cold. Which is good?

- Use oil cold. Air cooling will cause graphite dust flying, on the one hand, toxic, on the one hand there are security risks (caused by circuit short circuit). Water cooling is virtually out of use, taking into account the maintenance and maintenance of the CNC.

- Q: Electrolysis of CuCl2 solutions with graphite electrodes

- CuCl2 refers to a copper chloride ionization ionization ion and chloride ion in aqueous solution, the equivalent of CuCl2 does not exist, but there are only Cu2+ and Cl-, even if there is no electricity, the ionization will happen, because this is the nature of it.

- Q: I remember the more lively metal, the electron?

- Metal ion is more inert electron, graphite electrode for electrolytic salt solution containing the same amount of substance A and C two metals, C first precipitated, so C is copper. In a dilute sulfuric acid with H2 precipitation, certainly not a copper. The more active metal betatopic ability is strong, have the corresponding ion electronic ability weaker. First metal ions corresponding to metal electrons are not active.

- Q: How large is the permissible overload current per square millimeter of the graphite electrode cross section?

- Overhead wires, radiating the best conditions, allowed the current largest. The insulated wire in the house is laid in the wall, which has the worst heat release conditions and the smaller permissible current, so there are different safety currents.

Send your message to us

Hp 450 Graphite Electrodes RP HP UHP for Steelmaking Electric Arc Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches