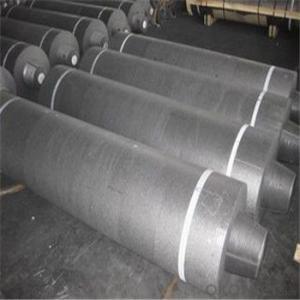

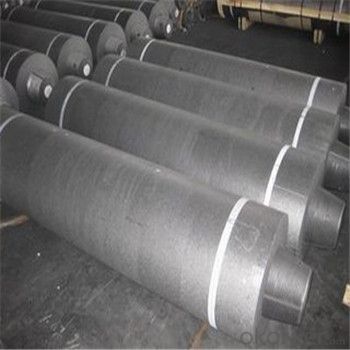

High Quality Machining Graphite Electrodes for Steel Making with Guarantee

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite Electrode for steel making

Applications

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

Programmable properties

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

FINE-GRAIN SPECIALTY GRAOHITE FXG-1

Physical and chemical index

Item | Unit | Guarantee Value | Typical Value |

Max Grante Size | mm | 0.8 | 0.8 |

Bulk Density | g/cm3 | ≥1.70 | 1.73 |

Specific Resistance | μΩ.m | ≤8.5 | 7.5 |

Bending Strength | MPa | ≥10.0 | 11.0 |

Compressive Strength | MPa | ≥24.0 | 27.0 |

Thermal Conductivity | W/(m.k) | ≥120 | 150 |

CTE (100-600)℃ | 10-6/℃ | ≤2.5 | 2.2 |

Ash Content | % | ≤0.3 | 0.09 |

FINE-GRAIN SPECIALTY GRAOHITE FXG-2

Physical and chemical index

Item | Unit | Guarantee Value | Typical Value |

Max Grante Size | mm | 0.8 | 0.8 |

Bulk Density | g/cm3 | ≥1.73 | 1.76 |

Specific Resistance | μΩ.m | ≤8.0 | 7.0 |

Bending Strength | MPa | ≥12.0 | 12.5 |

Compressive Strength | MPa | ≥31.0 | 34.0 |

Thermal Conductivity | W/(m.k) | ≥130 | 160 |

CTE (100-600)℃ | 10-6/℃ | ≤2.5 | 2.1 |

Ash Content | % | ≤0.3 | 0.09 |

FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the factors affecting the service life of graphite electrode in ultra high power arc furnace?

- China's graphite electrode quality standard (YB/T4090-2000) to evaluate the quality of the ultra high power graphite electrode is defined 6 physicochemical indexes, including resistivity, flexural strength, elastic modulus, bulk density and linear expansion coefficient as the quality evaluation index, ash as a reference index.

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- When the tool is broken, it will not only stop the continuous processing of the steel, but also affect the quality of the product, which will lead to the scrap of the parts and the waste of the material. Considering the foreseeable future, the graphite electrode will occupy a high position, usually used equipment for processing graphite electrode the highest efficiency mold manufacturers will unremittingly, expand and between those determined to use the hard steel processing manufacturer competition gap. The foundation of micro cutting tools, in terms of graphite electrodes, is one of its most magical words: "high speed."". The spindle speed of the high speed machining center is up to 30000~60000r/min, and the feed speed can be increased to shorten the processing period and improve the quality of the surface and edge. The motor needed to drive this type of spindle is relatively small and light, which helps to reduce cutting power and reduce tool breakage. This is critical because many of the electrodes are complex, and their production involves small, easily broken micro tools (see Figure 1).

- Q: What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- Because the carbon containing ash, a graphite resistor 2-3 times, so the use of graphite electrode is better.

- Q: What is the reason that the current cannot be increased when the graphite electrode is used for anode electrolysis?Add calcium chloride and sodium bicarbonate into electrolytic water

- Because in the process of electrolysis of water in cathode electron generated hydroxyl, the alkaline solution increased. But with the hydroxyl reaction of sodium carbonate and sodium bicarbonate, carbonate and calcium ions exist at the same time, must produce the precipitation of calcium carbonate, the ion in the solution is reduced, thereby conductive resistance increases. Thus weakened over time current cannot be raised

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- For operators, copper is certainly better, graphite will have dust, the human body has serious harm

- Q: Synthesis techniques of carbon nanotubes

- Laser evaporation is an effective method for the preparation of single-walled carbon nanotubes. Single walled carbon nanotubes and single-walled carbon nanotube bundles were prepared by evaporation of carbon targets doped with Fe, Co, Ni or their alloy by high energy CO2 laser or Nd/YAG laser. The diameter of the tubes can be controlled by laser pulses. The researchers found that the shorter the laser pulse interval, the higher the yield of SWNTs, while the SWNT structure was not affected by the pulse interval time. Using CO2 laser evaporation method for single wall carbon nanotubes at room temperature, if the use of fast imaging technology and emission spectra can be observed in morphology of smoke and carbon containing debris flow evaporation in argon, the diagnostic technology makes the growth process of single wall carbon nanotubes tracking possible. The main disadvantage of laser evaporation (ablation) is that the purity of single walled carbon nanotubes is low and easy to entangle.

- Q: What kind of asphalt is better for natural graphite coating?

- Special graphite mainly to high quality petroleum coke as raw material, coal tar or synthetic resin as binder, the raw material preparation, mixing, kneading, pressing, crushing, mixing, molding, roasting, soaking, repeatedly repeated purification and graphitization, and made the processing machine. It is generally used in the aerospace, electronics and nuclear industry sectors. It includes pure graphite, high purity, high strength, high density and pyrolytic graphite.

- Q: Can Naiduo high temperature graphite

- The reinforced graphite gasket is made of flexible graphite tape or flexible graphite and is molded into ring products of different sizes. Suitable for hot water, high temperature, high pressure steam, heat exchange liquid, nitrogen gas, organic solvent, hydrocarbon, low temperature liquid and other medium. Used in compressors, machines, pumps, valves, chemical instruments, instruments, etc..

- Q: Carbon graphite electrode and what is the difference?

- The material is composed of carbon carbon, but without graphite, after molding sintering temperature is only more than 1000 degrees, no graphitization.

- Q: What about graphite electrodes for steel mills?

- For steel and iron alloys, graphite electrodes are used, when powerful currents pass through electrodes into the melting zone of the electric furnace to produce an arcThe electric energy is converted into heat energy, and the temperature is increased to about 2000 degrees, so as to achieve the purpose of smelting or reaction. In addition, the electrolytic goldWhen the magnesium, aluminium and sodium are used, the anode of the electrolytic cell is also made of graphite electrode. The resistance furnace for carborundum is also made of graphite electrode as the burnerConductive material.

Send your message to us

High Quality Machining Graphite Electrodes for Steel Making with Guarantee

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches