UHP Graphite Electrode Price Trend

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 MT m.t.

- Supply Capability:

- 2000 MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production Description

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to

700mm. Our products own the following characteristics: low electric resistance, good electric and

thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

package: In pallets

Usage: In steel making

Graphite Electrode Specifications

ITEM | Unit | UHP | HP | RP | |||

350-450mm | 500-700mm | 350-450mm | 500-700mm | 350-450mm | 500-700mm | ||

Bulk Density | g/cm³ | 1.65-1.73 | 1.65-1.74 | 1.62-1.72 | 1.62-1.72 | 1.54-1.61 | 1.54-1.61 |

Specific Resistivity | μΩM | 4.2-6.0 | 4.5-5.8 | 5.5-6.8 | 5.6-7.0 | 7.0-9.0 | 7.0-9.5 |

Flexural Strength | Mpa | 11.0-15.0 | 10.0-14.0 | 10.5-14.5 | 10.0-13.5 | 8.0-11.0 | 7.0-10.0 |

Elastic Modulus | Gpa | 8.5-11.0 | 8.0-12.0 | 6.0-9.3 | |||

CTE (100-600)°C | 10-6/C | 1.30-1.45 | 1.65-1.95 | 1.85-2.25 | |||

ASH | % | 0.1-0.3 | 0.1-0.3 | 0.1-0.3 | |||

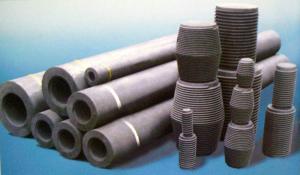

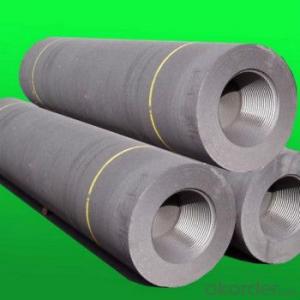

PICTURES:

- Q: Is graphite electrode good for foreign trade?

- Foreign sales commission depends on the price you talk to the customer, and the profit is objective.

- Q: Why should supercapacitors use graphite as electrode material?

- Because the graphite material's electrochemical stability is good, can let the super capacitor withstand the higher monomer voltage. The electrode is not easy to wear out.

- Q: What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- Because the carbon containing ash, a graphite resistor 2-3 times, so the use of graphite electrode is better.

- Q: What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- In the electrochemical process, the electrode should not affect the reaction on the working electrode, so platinum and graphite are often chosen

- Q: The reason why graphite is used as electrode

- Good chemical stabilityGraphite has good chemical stability at room temperature. It can resist acid, alkali and organic solvent.

- Q: MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- The impact of carbon on the car is quite large, first of all, to reduce the power of the engine, that is, to make the power output uneven and gradually attenuated, in other words, more and more lack of force. Two is to increase fuel consumption, increase your financial burden.

- Q: Graphite graphite graphite graphite electrode what is the use?

- Natural graphite electrode is the main raw material with graphite, high purity flake graphite powder or high carbon flake graphite powder as raw material, because carbon or graphite powder purity is high, the effect of conductive graphite powder is better in smelting alloy steel, iron alloy, electrode graphite powder as raw material. The electrode produced, then the strong current through the melting zone, the arc electrode into the electric furnace, the electrical energy into heat, the temperature rises to 2000 degrees Celsius, so as to achieve the purpose of melting or reaction.

- Q: How can I electroplate iron? I would like to use graphite as an electrode. Iron is plated on graphite with iron solution, so it can be processed into iron parts. I wonder if it can be done

- Iron plating can be, with 2 valence iron, but on the graphite joint force is good, it is difficult to say, electroplating is bad, peeling is also common. Relatively speaking, iron parts on nickel plating is relatively simple, also more applicable

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- Is this principle. Graphite is a layer, each layer, each carbon is SP2 hybrid, and around three carbon connected, finally, between layer and layer formed delocalized covalent bond, making layer and layer can be connected. However, the delocalized covalent bond is not very stable, in attracting Yang Jizheng charge, delocalized covalent bond will certain destruction, the force between the graphite layer and the layer becomes small or not, so as to open.The black stuff is graphite

- Q: How about graphite electrode high-temperature oxidation resistant coating?

- The utilization ratio of graphite energy can reach more than 95%. Many kinds of antioxidant paint, it is recommended to directly find their technicians, you can give professional advice, according to the actual situation, the reasonable use of high-temperature oxidation resistant paint.

1. Manufacturer Overview

| Location | Shizuishan,China |

| Year Established | 2004 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | " Mid East;Western Europe;North America" |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

UHP Graphite Electrode Price Trend

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 MT m.t.

- Supply Capability:

- 2000 MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords