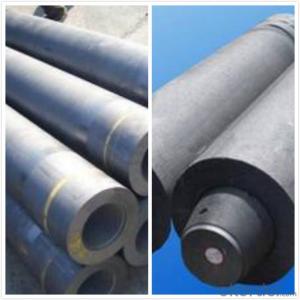

Steel Industry Good Quality Graphite Electrode for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Jiangsu, China (Mainland) | Brand Name: | JL | Application: | EAF&LF |

| Diameter: | 100 to 600mm | Length: | 1500 to 2700 mm | Grade: | HP (High Power) |

| Resistance (μΩ.m): | <7< p=""> | Apparent Density (g/cm³ ): | >1.65 | Thermal Expansion: | 2.5 |

| Flexural Strength (N/㎡): | 12 | Ash: | <0.3< p=""> | Nipple: | 3TPI,4TPI,4TPIL |

Packaging & Delivery

| Packaging Details: | wooden case |

| Delivery Detail: | one to three months |

Graphite Electrode

----------------------------------------------------------------------------------------------------------------------

diameter from 50mm to 600mm (2" to 24")

grades including RP, HD, HP, SHP, UHP.

Nipples: 3 TPI or 4 TPI.

----------------------------------------------------------------------------------------------------------------------

We have full set of production line for graphite electrodes.

Our products are characterized by superior compact structure, good electrical and thermal conductivity, high resistance to oxidation and corrosion in high temperature. The regular power graphite electrodes graphite electrodes for heavy industrial arc furnaces, steel mills, foundries, and other applications.

As one of the most professional graphite electrode manufacturers in China, passed ISO9001:2000 certified.

We're glad to quote you a most competitive price according to your specification.

----------------------------------------------------------------------------------------

Specifications

G-High Graphite Electrodes have the properties of superior electric conductivity and chemical stability, high mechanical strengt

G-High Graphite Electrodes are made from Petroleum Coke and Needle Coke, using Coal Tar Pitch as agglutinant, produced through the process of calcining, mixing, kneading, compressing, roasting, graphitization and machining, etc.

G-High Graphite Electrodes have the properties of superior electric conductivity and chemical stability, high mechanical strength, less impurity, seismic performance in high temperature. G-High Graphite Electrodes are mainly used for steel-making in electric furnaces, mineral hot furnaces and electric resistance furnaces.

Graphite Electrodes conduct electric current into the furnace. Electric current produces arc in the smelting district, when the temperature increases to about 2000°C, smelting begins. Our series of Graphite Electrodes are applicable to the common furnaces and high power furnaces with high voltage and short arc. G-High Graphite Electrodes are classified into three classes.

NP Graphite Electrodes: mainly used in common power electric ovens for smelting steel, smelting silicon and smelting yellow phosphorus;

HP Graphite Electrodes: mainly used in high power electric ovens for smelting steel;

UHP Graphite Electrodes: mainly used in ultra high power electric ovens for smelting steel.

- Q: What is the striking electrode in the die making? Where is the technical point?

- Technology of EDM should master the characteristics of electric discharge between tool electrode and workpiece is not in direct contact, but there is a gap, the gap is generally between 0.05~0.3mm, sometimes may reach 0.5mm or more, full of fluid, processing by high voltage pulsed discharge, the discharge of corrosion the workpiece.

- Q: What is the difference between pyridine type nitrogen and graphite type nitrogen?

- The fine structure graphite is the raw material used in the production of graphite electrode. The particle size is relatively small, generally below 0.5.

- Q: How to solve the problem of graphite electrode being crushed during electrolysis

- There's no way. It's an industrial problem, and that's how graphite works.

- Q: Which department in the steel plant needs graphite in large quantities?

- For steel and iron alloys, graphite electrodes are used, when powerful currents pass through electrodes into the melting zone of the electric furnace to produce an arcThe electric energy is converted into heat energy, and the temperature is increased to about 2000 degrees, so as to achieve the purpose of smelting or reaction. In addition, the electrolytic goldWhen the magnesium, aluminium and sodium are used, the anode of the electrolytic cell is also made of graphite electrode. The resistance furnace for carborundum is also made of graphite electrode as the burnerConductive material.

- Q: The production of one ton of steel required graphite electrode

- Not sure, look at your such as what is charge, and your smelting level.If the proportion of molten iron to the furnace is high, then the electrode consumption is low, 0.7kg/t, or lower. If it's cold, 1-2kg/t.

- Q: How does graphite produce solar cells?

- Gerrit J said: "despite the modifications, but the inherent nature of graphene remains unchanged, is a significant advantage of composite materials."

- Q: Iron and graphite as electrodes and Nacl as electrolyte solutions. Why do they produce electric current? Graphite and iron react not with solution, can they be connected by wires?

- Graphite here acts only as an electrode, and the real reaction on the graphite is oxygen, the galvanic cell reaction called iron oxygen corrosion

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- Is this principle. Graphite is a layer, each layer, each carbon is SP2 hybrid, and around three carbon connected, finally, between layer and layer formed delocalized covalent bond, making layer and layer can be connected. However, the delocalized covalent bond is not very stable, in attracting Yang Jizheng charge, delocalized covalent bond will certain destruction, the force between the graphite layer and the layer becomes small or not, so as to open.The black stuff is graphite

- Q: How do graphitized electrodes differentiate between high power and low power?

- In an electrolytic cell, the current from a class called graphite anode plate into the electrolyte electrolysis industry, the anode is made of plate shape, so called graphite anode plate, widely used in electroplating, wastewater treatment, industrial anti-corrosion equipment or special materials.

- Q: What is the composition of petroleum coke and what is its use?

- Medium sulphur and common cooked coke; used in large quantities for aluminium smelting. High sulfur, ordinary coke is used in chemical production, such as the manufacture of calcium carbide, silicon carbide, etc., but also as a metal casting and other fuels. Most of the petroleum coke produced in China belongs to low sulfur coke, which is mainly used for smelting aluminium and making graphite.

Send your message to us

Steel Industry Good Quality Graphite Electrode for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches