Graphite Electode for Steel Making Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite Electrode for Steel Making Industry

Composite of Graphite Electrode for Steel Making Industry

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm.

Applications of Graphite Electrode for Steel Making Industry:

It is used for the electric arc furnace steel making. (About 70-80% graphite electrode is used for steel making).

It is used for the submerged arc furnace, including melting iron alloy, pure silicon, yellow

phosphorus,matte, calcium carbide and so on.

It is used for the resistance furnace, such as the graphite making, melting glass, silicon carbide

making and so on.

Advantages of Graphite Electrode for Steel Making Industry:

low electric resistance

good electric and thermal conductivity

high oxidation resistance

high mechanical strength

high machining accuracy

greater resistance to thermal and mechanical shock

28 drums counter-flow calcining furnace

Auto-control dosing system

Germany Enrich kneading system

3500MT vertical tamping&horizontal extruding press

Auto-comtrol ring backing furnace

Germany Feist-incon 2nd Baking Kiln

High pressure imprgnation system

Acheson high power DC graphitizing furnace

Japan Nachi NC electrode machining line

America lngersoll NC electrode machine line

Japan Nachi NC nipple machining line

Carbon fiber production line

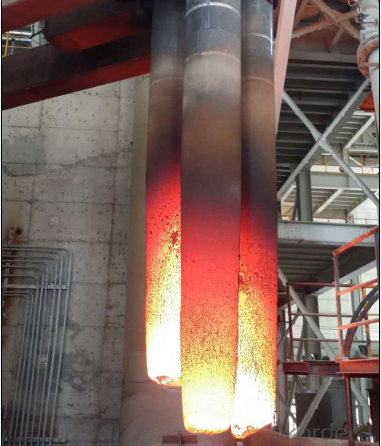

Graphite Electrode for Steel Making Industry Images

Specifications of Graphite Electrode for Steel Making Industry:

Item | Unit | Regular-power | Impregnated | ||||||

φ75- | φ150- | φ250- | φ350- | φ75- | φ250- | φ400- | |||

130 | 225 | 300 | 500 | 200 | 350 | 500 | |||

Specific Resistance (≤) | E | μ Ω·m | 8.5 | 9 | 9 | 9 | 8 | 8 | 8 |

N | 8 | 8 | 8 | 8 | 7.5 | 7.5 | 7.5 | ||

Bending Strength (≥) | E | MPa | 9.8 | 9.8 | 7.8 | 6.4 | 10 | 9 | 8 |

N | 13 | 13 | 13 | 13 | 15 | 15 | 15 | ||

Elastic Modulus (≤) | E | GPa | 9.3 | 9.3 | 9.3 | 9.3 | 12 | 12 | 12 |

N | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||

Bulk Density (≥) | E | g/cm3 | 1.58 | 1.52 | 1.52 | 1.52 | 1.58 | 1.58 | 1.58 |

N | 1.63 | 1.63 | 1.68 | 1.68 | 1.68 | 1.68 | 1.68 | ||

C.T.E.(≤) | E | 10-6/°C | 2.9 | 2.9 | 2.9 | 2.9 | 2.7 | 2.7 | 2.7 |

(100-600°C) | |||||||||

| N | 2.7 | 2.7 | 2.8 | 2.8 | 2.5 | 2.5 | 2.5 | |

Ash(≤) |

| % | 0.5 | 0.5 | 0.5 | 0.5 | 0.3 | 0.3 | 0.3 |

FAQ of Graphite Electrode for Steel Making Industry

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q9:Can you accept OEM for Ceramic Fiber Insulation Roll?

A:YES! We can according your demand to produce.

Q10:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- When the tool is broken, it will not only stop the continuous processing of the steel, but also affect the quality of the product, which will lead to the scrap of the parts and the waste of the material. Considering the foreseeable future, the graphite electrode will occupy a high position, usually used equipment for processing graphite electrode the highest efficiency mold manufacturers will unremittingly, expand and between those determined to use the hard steel processing manufacturer competition gap. The foundation of micro cutting tools, in terms of graphite electrodes, is one of its most magical words: "high speed."". The spindle speed of the high speed machining center is up to 30000~60000r/min, and the feed speed can be increased to shorten the processing period and improve the quality of the surface and edge. The motor needed to drive this type of spindle is relatively small and light, which helps to reduce cutting power and reduce tool breakage. This is critical because many of the electrodes are complex, and their production involves small, easily broken micro tools (see Figure 1).

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- Can't。 During electrolysis, there is depletion of sulfite ions.

- Q: Specification for graphite electrodes commonly used in steel works

- General specification for graphite electrode diameter Phi 300 Phi 500mm, Phi Phi 550 - the current usage of 800mm graphite electrodes is also great, the graphite electrode length was between 1600 and 2700mm.

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- Graphite is characterized by coarse particles, fine particles and ultrafine particlesFor different processing, you can choose different particles, the smaller the particle size, the higher the accuracyCopper has good conductivity and thermal conductivity and is used in many occasionsBut there are many factors to consider in the choice between the two

- Q: Synthesis techniques of carbon nanotubes

- Carbon nanotube discharge using graphite electrode is one of the earliest studies in various synthetic techniques. The researchers did a lot of work in optimizing arc discharge for carbon nanotubes. In recent years, in addition to people by adjusting the current and voltage, pressure and velocity change, change the electrode composition, improved electrode feeding mode optimization of arc discharge process, but also through changes the arc medium, simplified arc device. In the process of preparing carbon nanotubes, arc method is mature by changing the arc discharge conditions, catalyst, electrode size, feed mode, the distance between the poles and the raw materials. The carbon nanotubes formed by arc method are straight and wall (multi wall or even single wall). But the production rate is low, the arc discharge process is difficult to control, and the preparation cost is too high. The industrial scale production needs to be explored.

- Q: What kind of asphalt is better for natural graphite coating?

- Main types of graphite electrode with petroleum coke and needle coke, coal tar pitch as binder, calcination, mixing, kneading, pressing, baking and graphitization, and made the processing machine, is a conductor in an electric arc furnace to form arc release electricity for heating and melting of the charge, according to the quality index level, can is divided into ordinary power, high power and ultra high power.

- Q: Can graphite be used as an electrode for electrolysis of silver in silver nitrate?

- Xiaoyi Liyang said the principle is correct, but can get silver? I think we can solve the problem if we take proper measures to get the silver elements, such as separating the anode and the cathode from the salt water!

- Q: Graphite powder produced by graphite electrode and what we usually call graphite is a kind of thing?

- Coal tar pitch as binder is made by calcination, batching, kneading, pressing, roasting, graphitization and machining

- Q: What are the losses in graphite electrode?

- So tell, this problem is to answer a lot, graphite under high temperature oxidation, generally around 400 degrees, began a slight oxidation, but the human eye is to be observed, with the increase of temperature, the graphite oxide will increase, this time should be used to protect gas or vacuum to protect what you said is, nitrogen protection, and general protection of nitrogen can reach more than 2000 degrees, if the high temperature to 3800 degrees, will you say that vapor formed in graphite surface. To achieve this temperature, it is necessary to add inert gas to achieve, otherwise, can not reach, generally to 4350 degrees, the graphite began to soften.

- Q: Iron and graphite as electrodes and Nacl as electrolyte solutions. Why do they produce electric current? Graphite and iron react not with solution, can they be connected by wires?

- Graphite here acts only as an electrode, and the real reaction on the graphite is oxygen, the galvanic cell reaction called iron oxygen corrosion

Send your message to us

Graphite Electode for Steel Making Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords