Graphite Electrode Manufacturer in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

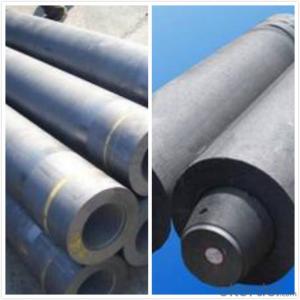

China Manufactured Graphite Electrode

Product Description:

Graphite electrode is made from the domestic petroleum coke as well as high quality needle coke which are widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials

Other related properties include: Graphite / Steel Welding Electrode (AWS E6013(J421))

Graphite / Steel welding electrode belongs to carbon steel electrode, which is commonly used for automobile bodies, ornamental iron, metal furniture, truck frames and bodies, farm implementations, machinery guards and storage tanks.

.

Main Product Features:

Stable arc

More resistant to splatter and smoke inhalation.

Higher deposition efficiency

Excellent welding performance

Easy restrike.

Our welding electrodes have more resistance to splash and smoke, easy restart weld quality design also including resistances to dust and smoke.

Product Images:

Product Specifications:

Minimum Order Quantity: | 10 pc | Unit: | pc | Loading Port: | China main port |

Supply Ability: | 2000000 pc/month | Payment Terms: | TT or LC | Package: | 托盘包装 |

The welding electrode is suitable for all position welding of steel sheets and irregular joints even under unfavorable conditions.

Excellent welding technological performances.

The arc is stable and the spatter loss is negligible.

The slag is fluid and when hardened it is compact and easy to remove.

Better for welding structures of steel sheets. Vehicles, buildings, machinery-manufacture, vessels and various structures of low carbon steel.

Product Applications:

Graphite Electrode is used for the electric arc furnace steel making. On average 70-80% of graphite electrode is used for steel. This can also be used for the submerged arc furnace, including melting iron alloy, pure silicon, yellow phosphorus, matte, calcium carbide etc. Other usages include: graphite making, melting glass and silicon carbide.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30% T/T in advance, with the balance before shipment. L/C at sight is also acceptable. Other payment term can be discussed with specific order.

- Q: Use of graphite in steelmaking

- Application of graphite electrode in smelting, alloy steel, iron alloy, graphite electrode, the strong current through the melting zone, the arc electrode into the electric furnace, the electrical energy into heat, the temperature rises to 2000 degrees Celsius, so as to achieve the purpose of melting or reaction.

- Q: Where is the graphite electrode scrap?

- Vortex ring formed in a highly ionized internal ICP can be regarded as the secondary coil of the transformer is only one turn, and the work coil water is equivalent to the primary winding of the transformer, the coupling between them, the strength and direction of the magnetic field varies with time, the electronic and ionic field acceleration continuously changes its direction of motion. Lead to Joule heating effect and incidental ionization. This gas forms a new and stable "electric flame" light source in the quartz torch tube in a very short time.

- Q: What is the graphite furnace electrode with a diameter of 400?

- With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- External electronic wire and the directional movement of ions in the solution of the directional movement between the poles of a closed loop, so that the two electrode reaction, electron transfer process, ordered a current converting chemical energy to electrical energy.Attention, here, "the ion does not go ashore, the electron does not enter the water"." That is the external circuit of graphite electrode is composed of electron flow and electrolyte ion flow; graphite electrode is to produce voltage and electrolyte, and to provide or absorb electrons

- Q: What's the use of carbon?

- Common power graphite electrode. Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q: Iron and graphite as electrodes and Nacl as electrolyte solutions. Why do they produce electric current? Graphite and iron react not with solution, can they be connected by wires?

- What happens is oxygen etching negative pole: Fe-2e-=Fe2+ positive electrode: O2+2H2O+4e-=4OH-, of course, the current is produced.

- Q: What kinds of carbon are there?

- Graphite electrode class can be divided into ordinary power graphite electrode according to the allowable current density. High power electrode and ultra high power electrode.

- Q: What does graphite electrode GSK mean?

- Graphite is made of high-strength graphite, it is a kind of graphite grade specification.

- Q: What is the composition of petroleum coke and what is its use?

- Mainly used for making carbon products, such as graphite electrodes, anode arc, steel, non-ferrous metals, with aluminum for use; silicon carbide products, such as grinding wheel, rubber, sandpaper; producing goods for the production of synthetic fiber, calcium carbide acetylene and other products; also can be used as fuel for fuel, but for grading impact for grinding superfine grinding, through the JZC-1250 device can be made of coke powder after combustion, using coke powder as fuel is mainly some glass factory, coal water slurry plant etc..

- Q: How large is the permissible overload current per square millimeter of the graphite electrode cross section?

- 9A/mm2 safety current should be bare overhead, 5A/mm2 is obviously insulation lines, the indoor environment standards.

Send your message to us

Graphite Electrode Manufacturer in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords