High Quality Graphite Electrode Chemistry for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications

Graphite Electrodes Used for steel making in arc furnace

Dia:200mm-500mm

Super quality

Competitive price

2. Specifications for RP, HP, UHP graphite electrodes with nipples:

RP | HP | UHP |

Electrode: Bulk Density≥ 1.56g/cm3 Elastic Modulus≤ 9.3GPa Thermal Expansion Coefficient≤ 2.7x10 -6/°C Ash≤ 0.5%

Nipple: Bending Strength≥ 14.0MPa Elastic Modulus≤ 13.7GPa Thermal Expansion Coefficient≤ 2.5 x10 -6/°C Ash≤ 0.5% | Electrode: Bulk Density≥ 1.65g/cm3 Elastic Modulus≤ 10.0GPa Thermal Expansion Coefficient≤ 2.2x10 -6/°C Ash≤ 0.3%

Nipple: Bending Strength≥ 16.0MPa Elastic Modulus≤ 14.0GPa Thermal Expansion Coefficient≤ 2.0 x10 -6/°C Ash≤ 0.3% | Electrode: Bulk Density≥ 1.68g/cm3 Elastic Modulus≤ 14.0GPa Thermal Expansion Coefficient≤ 1.9x10 -6/°C Ash≤ 0.2%

Nipple: Bending Strength≥ 18.0MPa Elastic Modulus≤ 16.0GPa Thermal Expansion Coefficient≤ 1.4 x10 -6/°C Ash≤ 0.2% |

3. Packing:

In wooden cases strapped with steel bands.

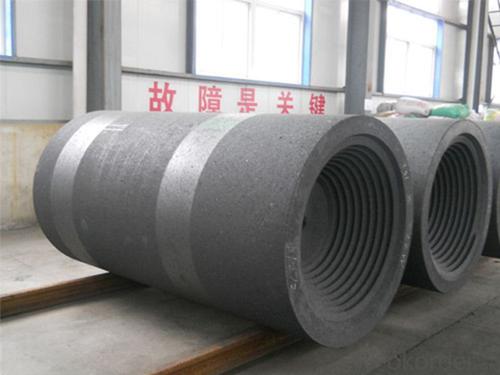

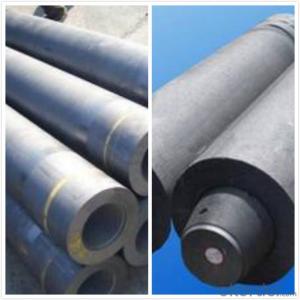

4.Pictures of Graphite Electrodes Factory

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty Graphite Electrodes with high power ?

Our factory could produce qualified products and good delivery time, cause we have many graphite electrodes in stock to our clients. So we can offer you stock products if you need urgent.

②How to guarantee the quality of the products Graphite Electrodes with high power?

We have established purchasing quality control system, and we have inspector in the factory to check the quality. each good should be appreoved by the inspectors ,then, could be permit to do shipment.;

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory to do production or do delivery as cusotmers' request.

- Q: What are the factors affecting the service life of graphite electrode in ultra high power arc furnace?

- The ultra high power graphite electrodes produced in China are 300mm, 350mm, 400mm, 450mm, 550mm, 600mm, 650mm, 500mm and 700mm, with lengths of 1600mm, 1800mm, 2000mm, 2200mm, 2400mm and 2700mm.

- Q: Classification, uses and manufacturers of graphite electrodes

- The difference between graphite electrodesMainly from the current, density, resistance, bending strength, ash parameters are measured

- Q: What is the reason that the current cannot be increased when the graphite electrode is used for anode electrolysis?Add calcium chloride and sodium bicarbonate into electrolytic water

- The reason is that the resistance increases continuously, the number of ions is limited, and the conductivity is limited

- Q: Graphite can be used in acid towers in chemical plants because of graphite

- Ultra high power graphite electrode. A graphite electrode that allows current densities greater than 25A/ cm 2 is allowed. Mainly used in ultra high power steelmaking arc furnace

- Q: The difference between graphite electrode and graphite rod

- The two materials are different.Graphite electrode is mainly in the petroleum coke and needle coke, coal tar pitch as binder, calcination, mixing, kneading, pressing, baking and graphitization, and made the processing machine, is a conductor in an electric arc furnace to form arc release electricity for heating and melting of the charge, according to the quality index level, can is divided into ordinary power, high power and ultra high power.

- Q: Why should graphite paper be placed between the heater and the graphite electrode?

- Determine the thickness of the graphite bowl, the thickness of the graphite bowl is generally 3 mm -6 mm, three, determine the diameter of the heater, according to the diameter of the crucible and the thickness of the graphite bowl, calculate the inner diameter of the heater. The gap in the quartz crucible diameter phi = +2 times is +2 times the wall thickness of stone bowl bowl and graphite heater if the graphite bowl wall thickness is a, graphite bowl gap and heater for B (b=5 mm), phi = Phi Phi +2a+2b= within the outer crucible outer crucible +2 (a+b) four, to determine the effective heater the height after practice, the effective length of the quartz crucible heater is high 1.6 to 1.8 times.

- Q: The production of one ton of steel required graphite electrode

- Can not generally say, a ton of steel production consumes much of graphite electrode.

- Q: Why is the production of one ton of ultra high power graphite electrode requires 1.05 tons of coke?

- Petroleum coke is divided into needle coke and sponge coke and projectile reef, fixed carbon content components of petroleum coke is around 80%

- Q: Iron and graphite as electrodes and Nacl as electrolyte solutions. Why do they produce electric current? Graphite and iron react not with solution, can they be connected by wires?

- Because the metal activity order form sodium potassium calcium magnesium aluminum, zinc and tin lead (hydrogen), mercury copper silver platinum, iron in the front row because of water water hydrogen, ionized hydrogen ions by iron replacement

- Q: Can high-purity graphite be used as an electrode?

- The thin and deep bone electrode can not be deformed, and the pure graphite electrode is brittle. It is better to break or deform, and can bear high temperature without deformation.

Send your message to us

High Quality Graphite Electrode Chemistry for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords