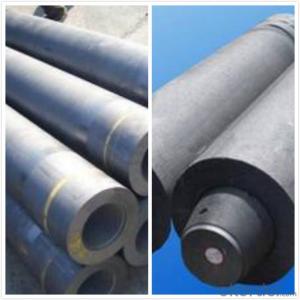

350mm Graphite Electrode RP, HP, UHP for Steel Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Diameter:40 - 600mm or1.6"-24"

2.Length: 250 - 2400mm or10"-96"

3.Grades:RP, RPI, HP, SHP, UHP

Nipples:3-4TPI

ISO9001:2000

Graphite Electrode for steel making

Applications

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

Programmable properties

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

Specifications

Item | Unit | Regular-power | Impregnated | ||||||

φ75- | φ150- | φ250- | φ350- | φ75- | φ250- | φ400- | |||

Specific Resistance (≤) | E | μ Ω·m | 8.5 | 9 | 9 | 9 | 8 | 8 | 8 |

N | 8 | 8 | 8 | 8 | 7.5 | 7.5 | 7.5 | ||

Bending Strength (≥)

| E | MPa

| 9.8 | 9.8 | 7.8 | 6.4 | 10 | 9 | 8 |

N | 13 | 13 | 13 | 13 | 15 | 15 | 15 | ||

Elastic Modulus (≤)

| E | GPa

| 9.3 | 9.3 | 9.3 | 9.3 | 12 | 12 | 12 |

N | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||

Bulk Density (≥)

| E | g/cm3

| 1.58 | 1.52 | 1.52 | 1.52 | 1.58 | 1.58 | 1.58 |

N | 1.63 | 1.63 | 1.68 | 1.68 | 1.68 | 1.68 | 1.68 | ||

C.T.E.(≤)

| E | 10-6/°C

| 2.9 | 2.9 | 2.9 | 2.9 | 2.7 | 2.7 | 2.7 |

N | 2.7 | 2.7 | 2.8 | 2.8 | 2.5 | 2.5 | 2.5 | ||

Ash(≤) | % | 0.5 | 0.5 | 0.5 | 0.5 | 0.3 | 0.3 | 0.3 | |

Item | Unit | High-power | Super high-power | Ultra high-power | ||||

φ200-400 | φ450-500 | φ350-400 | φ450-500 | φ300-400 | φ450-500 | |||

Specific Resistance(≤) | E | μ Ω·m | 7 | 7.5 | 6.5 | 7 | 6.2 | 6.5 |

N | 6.5 | 6.5 | 6 | 6 | 5.5 | 5.5 | ||

Bending Strength (≥)

| E | MPa

| 10.5 | 9.8 | 10.5 | 10 | 10.5 | 10 |

N | 15 | 15 | 16 | 16 | 16 | 16 | ||

Elastic Modulus (≤)

| E | GPa

| 12 | 12 | 13 | 13 | 14 | 14 |

N | 16 | 16 | 17 | 17 | 18 | 18 | ||

Bulk Density (≥)

| E | g/cm3

| 1.6 | 1.6 | 1.62 | 1.62 | 1.65 | 1.64 |

N | 1.7 | 1.7 | 1.71 | 1.71 | 1.72 | 1.72 | ||

C.T.E.(≤)

| E | 10-6/°C

| 2.4 | 2.4 | 2.2 | 2.2 | 1.5 | 1.5 |

N | 2.2 | 2.2 | 1.8 | 1.8 | 1.4 | 1.4 | ||

Ash(≤) | % | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |

FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Use of graphite in steelmaking

- Graphite can be used as an agent for carburizing in the steel making industry. Carburizing uses a wide range of carbonaceous materials, including synthetic graphite, petroleum coke, metallurgical coke, and natural graphite. Worldwide, the use of graphite for carburizing is still one of the main uses of earth like graphite.

- Q: The future of graphene

- Field of semiconductor materials. Graphene is considered to be an ideal material for replacing silicon. A large number of powerful enterprises have developed graphene semiconductor devices. The Han Guocheng Institute has developed a highly stable n type graphene semiconductor that can be exposed to air for a long time. Graphene silicon optoelectronic hybrid chip developed by Columbia University has broad application prospects in optical interconnection and low power photonic integrated circuit. IBM researchers have developed graphene field effect transistors with cutoff frequencies of up to 100GHz, with frequency performance far superior to the cut-off frequency of the most advanced silicon transistors of the same gate length.

- Q: What is the graphite furnace electrode with a diameter of 400?

- The variety and specifications of graphite electrodes used in modern EAF steelmaking are mainly determined by the technical parameters of the steelmaking furnace.

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- For the mold finishing, most of the time are red copper click, low loss, high precision, of course, higher precision, or requirements of copper tungsten alloy electrodes are also available

- Q: What kind of asphalt is better for natural graphite coating?

- The graphite electrode includes: (1) ordinary power graphite electrode. Allows the use of current density below 17A / cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, refining yellow phosphorus, such as ordinary power furnace. (2) oxidation resistance coating graphite electrode. A graphite electrode coated with an antioxidant protective layer is applied to form a protective layer that is conductive and resistant to oxidation at high temperature, thereby reducing electrode consumption during steelmaking. (3) high power graphite electrode. A graphite electrode with a current density of 18 ~ 25A / cm 2 is allowed to be used as a high power arc furnace for steelmaking. (4) ultra high power graphite electrode. Permits use of graphite electrodes with current densities greater than 25A / cm 2. Mainly used in ultra high power steelmaking arc furnace.

- Q: Classification of graphite electrodes

- Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q: Graphite electrode press device

- High power graphite electrodes. Graphite electrodes with a current density of 18 ~ 25A / cm 2 are allowed. They are mainly used in high power arc furnaces for steelmaking

- Q: Why is graphite a negative pole and copper is an anode?

- Electrolysis (Electrolysis) is the current through the electrolyte solution or molten electrolyte (also called electrolyte), caused by the redox reaction in the cathode and the anode, the electrochemical cell can occur when an external DC voltage in the electrolysis process.

- Q: How can I electroplate iron? I would like to use graphite as an electrode. Iron is plated on graphite with iron solution, so it can be processed into iron parts. I wonder if it can be done

- Iron plating can be, with 2 valence iron, but on the graphite joint force is good, it is difficult to say, electroplating is bad, peeling is also common. Relatively speaking, iron parts on nickel plating is relatively simple, also more applicable

- Q: Jiqiu conductive graphite electrode, how to compare with copper is relatively large resistance value?

- This is not a good estimate of the sheet graphite resistance after 5mm

Send your message to us

350mm Graphite Electrode RP, HP, UHP for Steel Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches