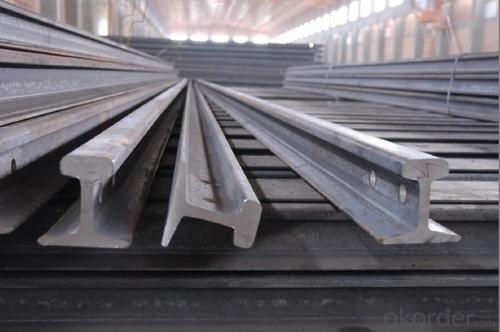

Mild Steel Light Rail 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Mild Steel Light Rail 55Q at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild Steel Light Rail 55Q are ideal for structural applications and are widely used in forest region, Mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.etc.

Product Advantages:

OKorder's Mild Steel Light Rail 55Q are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q235, 55Q

Certificates: ISO, SGS, BV, CIQ

Length:6m, 12m,12.5m

Package: Packed in bundles and shipped by break bulk or containers.

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: The previous track is seamed, there is no gap, is how to achieve

- Seamless rail not thousands of kilometers without gaps, but the 25 meter long rail welding up into hundreds of metres long or even thousands of meters long, and then in the shop on the embankment, or the gap between 11 mm and a section of a seamless rail, now Shanghai Nanjing line is 303 km long ultra long seamless rail. Seamless rail to solve the thermal expansion and contraction by slot number is not enough, now solve the thermal expansion and contraction in two ways: one is the long rail itself under all temperature stress, will be locked in the long rail sleepers, which is due to temperature change and contraction, this method is suitable for throughout the year the temperature is almost the same as in the southern region, Chinese. In some temperature difference regions should take another approach, namely the long rail itself does not bear the temperature stress, and stress or regular bleeding stress to automatic bleeding, make the long rail with temperature rise and free shrinkage, at the time of laying also try to choose the best temperature of laying the rail expansion value in the minimum range, so that regardless of temperature rising or falling, the rail expansion always control in the smallest range.

- Q: How do steel rails contribute to noise reduction in railway tracks?

- Steel rails contribute to noise reduction in railway tracks through their characteristics and design. Steel rails have a smooth and hard surface, which reduces friction and vibrations caused by train wheels. This reduces the overall noise generated by the train as it moves over the tracks. Additionally, steel rails are designed to be sturdy and secure, preventing any loose or shaky connections between the tracks. This stability further minimizes noise by preventing any unnecessary movement or rattling of the tracks.

- Q: Are steel rails used in railway track stabilizers?

- Steel rails are frequently employed in railway track stabilizers. They provide the essential strength and endurance required to sustain the weight of trains, guaranteeing stability and safety on railway tracks. These rails are meticulously crafted to endure substantial loads and extreme weather conditions. Typically forged from top-notch steel, they exhibit exceptional resistance to wear, deformation, and corrosion. The incorporation of steel rails in railway track stabilizers plays a crucial role in preserving the track's integrity, averting irregularities, and mitigating the likelihood of accidents.

- Q: How do steel rails contribute to track alignment?

- The railway industry relies heavily on steel rails to keep the tracks properly aligned. This is because steel rails play a crucial role in maintaining the correct position and straightness of the tracks, which ultimately enhances the stability and safety of the rail system. To begin, steel rails are manufactured with great precision, ensuring consistent dimensions and accuracy. This uniformity in size and shape is essential for maintaining the desired track alignment as it provides a stable and reliable foundation for the train wheels. The straightness of the steel rails guarantees that the tracks remain parallel, preventing any deviations or misalignments. In addition, steel rails possess high tensile strength, making them resistant to bending or warping under the weight and pressure exerted by passing trains. This strength enables the rails to maintain their original shape and position, even when subjected to heavy loads or extreme weather conditions. By remaining straight and true, steel rails effectively prevent any lateral movement or displacement of the tracks, which could potentially lead to alignment issues. Moreover, steel rails are designed to be durable and long-lasting. They can withstand the constant friction and wear caused by train wheels, ensuring that the tracks remain stable and aligned over an extended period. The resilience of steel rails helps minimize any gradual deformation or distortion that could impact track alignment, thus guaranteeing a smooth and safe passage for trains. Furthermore, steel rails often incorporate various fastening systems, such as clips or resilient pads, to securely hold them in place. These fastening systems play a critical role in maintaining track alignment by preventing any lateral or vertical movement of the rails. They also absorb vibrations and shocks caused by passing trains, reducing the risk of track misalignment and ensuring a stable and secure rail infrastructure. In conclusion, steel rails significantly contribute to track alignment by providing a stable, straight, and durable foundation for railway tracks. Their precise manufacturing, high tensile strength, durability, and fastening systems all work together to maintain the desired track alignment, ultimately enhancing the overall safety and efficiency of the rail system.

- Q: What are the requirements for steel rail storage and handling?

- The requirements for steel rail storage and handling include proper storage conditions, such as a dry and well-ventilated area to prevent corrosion. Handling should be done with appropriate lifting equipment to avoid damage or distortion to the rails. Additionally, rails should be stored in a way that prevents any bending or twisting, and they should be kept away from moisture, chemicals, and extreme temperatures.

- Q: How do steel rails contribute to train ride quality?

- Steel rails contribute to train ride quality in several ways. Firstly, steel rails provide a smooth and stable surface for the train to run on. The design and manufacturing of steel rails ensure that they are straight and free from any deformities or irregularities. This allows the train wheels to make consistent contact with the rails, reducing vibrations and providing a smoother ride. Additionally, steel rails have a high level of strength and durability. They are able to withstand the heavy loads and constant impact of the train, maintaining their shape and integrity over time. This stability and strength of the rails contribute to a more comfortable and secure ride for passengers. Steel rails also play a crucial role in maintaining the alignment and stability of the train. They are designed to be securely fastened to the sleepers or ties, which in turn are fixed to the ground. This ensures that the tracks remain in place and do not shift or move while the train is in motion. The stability of the tracks is essential for a smooth and safe ride, as any misalignment or movement could cause jolts and discomfort for passengers. Furthermore, steel rails are designed to reduce noise during train operations. The smooth surface and precise alignment of the rails minimize the amount of friction and noise generated as the train wheels roll over them. This contributes to a quieter and more enjoyable ride for passengers. In conclusion, steel rails are a critical component of train ride quality. They provide a smooth and stable surface, ensure alignment and stability, and reduce noise. These factors contribute to a comfortable, secure, and enjoyable experience for passengers during train travel.

- Q: Can steel rails be replaced with other materials?

- Yes, steel rails can be replaced with other materials such as concrete, composite materials, or even plastic. However, the choice of material would depend on factors such as cost, durability, and the specific requirements of the railway system.

- Q: Are steel rails used in freight trains?

- Yes, steel rails are commonly used in freight trains as they provide the necessary strength and durability to support heavy loads and ensure safe transportation.

- Q: How to repair welding rail?What kind of electrode is used in rail welding? What's the problem easily?

- The rail welding is divided into the docking and repair welding. Rail butt can use aluminium heat welding, with aluminum and iron oxide mixed in proportion, with mold fixed rail, fill the thermite at the seams, lit by magnesium. Because the operation is complex, the heat affected zone, is now rarely used now commonly used. Use special welder. But after welding to reduce the total length of a point.

- Q: Can steel rails be used for both passenger and freight trains?

- Yes, steel rails can be used for both passenger and freight trains.

Send your message to us

Mild Steel Light Rail 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords