Scaffold Guard Rail

Scaffold Guard Rail Related Searches

Scaffold Bridge Scaffold Alarm Scaffold Inspection Training Scaffold Hoist Scaffold Platform Scaffolding Roof Indoor Scaffold Tower Scaffold Brackets Scaffolding Wheels Scaffold For Sale Craigslist Scaffolding Access Hss Scaffold Tower Baker Scaffold Wheels Scaffolding Bars Research Scaffold Internal Scaffold Tower Best Scaffolding Scaffold Netting Scaffolding Width Scaffolding Props Scafolding Used Ring Lock Scaffolding For Sale Wedge Lock Scaffolding 9M Scaffold Tower Drywall Scaffolding Scaffolding Pulley 8M Scaffold Tower Scaffolding Certification Old Scaffolding For Sale Modular ScaffoldingScaffold Guard Rail Supplier & Manufacturer from China

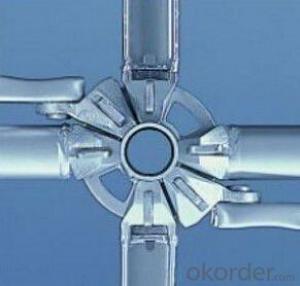

Scaffold Guard Rail is a safety product designed to provide protection and security on construction sites and other industrial areas. This product is made up of durable materials and is designed to withstand harsh conditions, ensuring the safety of workers and equipment. The guard rail system is easy to install and can be customized to fit various scaffolding configurations, making it a versatile solution for a wide range of applications.Scaffold Guard Rail is widely used in construction, maintenance, and other industrial settings where there is a need to protect workers and equipment from potential hazards. It is particularly useful in situations where there is a risk of falling or where there is a need to prevent unauthorized access to certain areas. The guard rail system can be used in conjunction with other safety equipment, such as safety nets and harnesses, to create a comprehensive safety solution that meets the specific needs of each project.

Okorder.com is a leading wholesale supplier of Scaffold Guard Rail, offering a vast inventory of this essential safety product. Our extensive selection ensures that we can meet the needs of any project, regardless of its size or complexity. We pride ourselves on providing high-quality products at competitive prices, and our commitment to customer satisfaction means that we are always available to assist with any questions or concerns that our clients may have. By choosing Okorder.com as your supplier, you can be confident that you are receiving the best possible Scaffold Guard Rail products for your needs.

Hot Products