Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale:

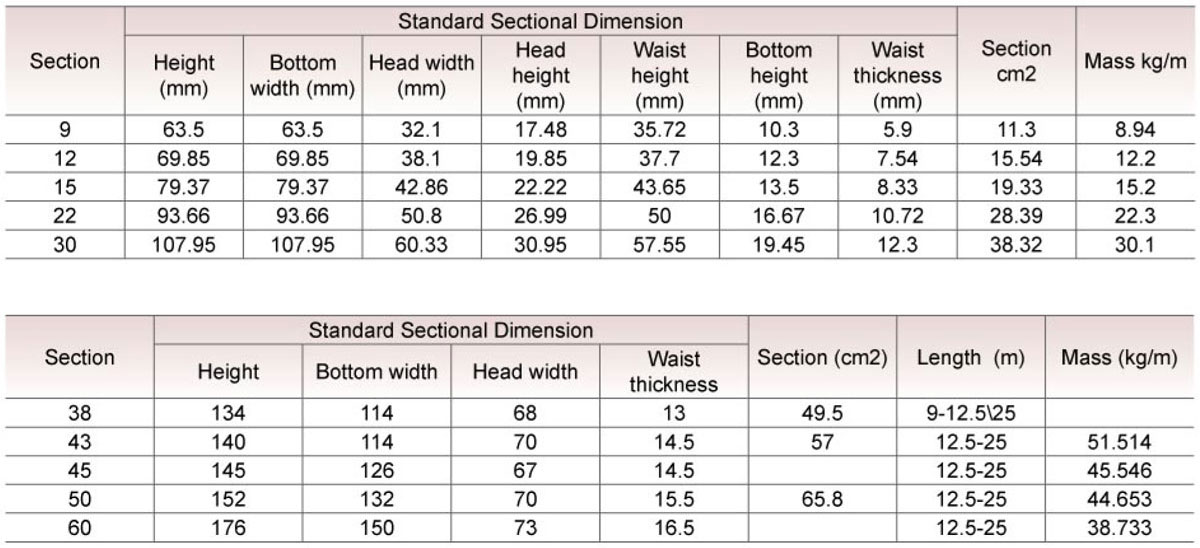

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Usages of Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale:

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel rails be used in high-speed railway switches?

- Certainly, steel rails are applicable for utilization in high-speed railway switches. Owing to their robustness, durability, and resistance to deterioration, steel rails are frequently employed in railway tracks. High-speed railway switches, commonly referred to as turnouts or points, are engineered to enable trains to transition from one track to another. These switches endure substantial forces and rapid velocities, necessitating the use of sturdy materials. Steel rails possess the requisite characteristics to endure such circumstances, rendering them suitable for high-speed railway switches. Moreover, steel rails can be fabricated with accurate measurements and sleek surfaces, guaranteeing the secure and efficient operation of the switches.

- Q: What is the average lifespan of steel rails in heavy traffic areas?

- The average lifespan of steel rails in heavy traffic areas can vary depending on several factors such as maintenance practices, the quality of the steel used, and the intensity of the traffic. However, on average, steel rails in heavy traffic areas can last anywhere from 30 to 40 years before needing significant repairs or replacements.

- Q: Are steel rails prone to wear and tear?

- Yes, steel rails are prone to wear and tear. Over time, the constant pressure and friction from heavy train traffic can cause the steel rails to deteriorate. Factors such as weather conditions, the weight of the trains, and the speed at which they travel can all contribute to the wearing down of the rails. As a result, the surface of the rails can become rough and uneven, leading to increased vibrations, noise, and potential safety hazards. To mitigate this wear and tear, regular maintenance and inspections are necessary to identify and repair any damaged or worn sections of the rails. Additionally, advancements in rail technology, such as the use of hardened steel or composite materials, are being explored to increase the durability and lifespan of steel rails.

- Q: What is the average lifespan of rail fasteners used with steel rails?

- The average lifespan of rail fasteners used with steel rails can vary depending on various factors such as the type of fasteners, quality of materials, maintenance practices, and environmental conditions. However, on average, rail fasteners can last anywhere between 25 to 50 years.

- Q: What are the different methods used for rail welding on steel rails?

- Rail welding on steel rails utilizes different methods, each with its own strengths and weaknesses. 1. Thermite Welding: A widely used technique involves a chemical reaction that generates intense heat, melting the rail ends and a pre-placed thermite mixture. The resulting molten metal solidifies to create a robust joint, known for its durability and high strength. 2. Flash Butt Welding: This method involves clamping the rail ends together and passing a high electric current through them. The resistance of the metal generates heat, causing the rail ends to melt, and they are then forged together under pressure. Flash butt welding produces efficient and durable joints of high quality. 3. Gas Pressure Welding: Oxy-fuel flames are used to heat the rail ends until they become plastic. Hydraulic pressure is then applied to press the rail ends together, creating fusion and a strong joint. Gas pressure welding is cost-effective and commonly used for routine maintenance and repairs. 4. Electric Arc Welding: This versatile method uses an electric arc to melt the rail ends, with a consumable electrode providing the filler metal. The molten metal solidifies to form a joint. While electric arc welding can be used for both field and factory welding, it is less common for rail welding due to its slower process and lower strength compared to other methods. 5. Magnetic Pulse Welding: A newer technique utilizes a high-intensity magnetic field to accelerate one rail end towards the other. The resulting impact generates heat, and the rail ends are fused together under pressure. Magnetic pulse welding is known for its speed and precision, but it is still being developed for rail welding applications. It is crucial to consider various factors, such as rail type, location, required strength, and welding equipment availability when choosing a welding method. Each method has its own advantages and limitations, and the decision should be based on the specific needs and requirements of the rail project.

- Q: How do steel rails handle changes in track alignment due to vibrations?

- Steel rails are designed to handle changes in track alignment due to vibrations by being flexible and resilient. The steel material allows the rails to absorb and distribute the vibrations, minimizing their impact on the track alignment. Additionally, proper maintenance and regular inspections ensure that any misalignments caused by vibrations can be promptly detected and corrected, ensuring the safety and stability of the railway track.

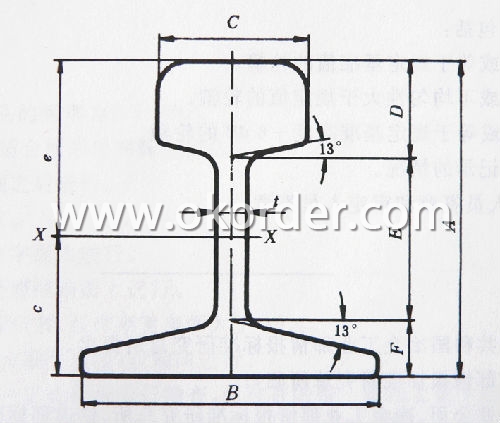

- Q: Why are the rails made of I-beam?

- The rail section of the modern use of "working" shape, divided into rail waist and bottom contact with the wheel rail, the middle rail base. Different routes have different requirements on rail strength, stability and wear resistance. Therefore, rail also has different specifications. Which one should be used on a route, taking into account economic and technical factors?.

- Q: Can steel rails be used in underwater environments?

- Yes, steel rails can be used in underwater environments. Steel is known for its high strength and resistance to corrosion, making it suitable for underwater applications such as bridges, offshore structures, and pipelines. The use of protective coatings and regular maintenance helps to mitigate the effects of corrosion caused by the water and ensure the longevity of steel rails in underwater environments.

- Q: What is the purpose of steel rails in railway systems?

- The purpose of steel rails in railway systems is to provide a sturdy and durable track for trains to travel on. Steel rails help distribute the weight of the trains evenly, ensuring a smooth and stable ride. They also help guide the trains along the designated path and prevent derailments.

- Q: Can steel rails be used for mountain or alpine railways?

- Yes, steel rails can be used for mountain or alpine railways. Steel is a durable and strong material that can withstand the rugged terrain and harsh weather conditions typically found in mountainous areas. It provides stability and support, making it suitable for the construction of railways in such challenging environments.

Send your message to us

Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords