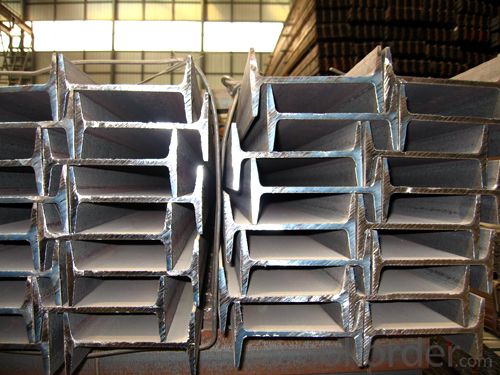

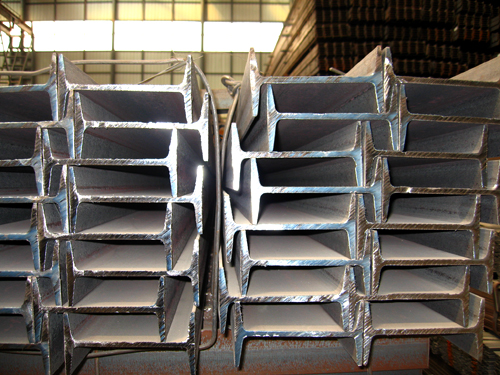

Hot Rolled Steel I-Beam For Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How is a steel I-beam different from other types of beams?

- A steel I-beam is different from other types of beams due to its distinctive shape, which resembles the letter "I". This design provides the I-beam with superior strength and load-bearing capabilities compared to other beam types. The flanges (horizontal sections) of the I-beam provide resistance against bending, while the web (vertical section) offers stability and support. The I-beam's unique construction makes it an ideal choice for structural applications where strength and durability are crucial.

- Q: What are the considerations for wind load design for steel I-beams?

- When designing steel I-beams for wind load, several key considerations need to be taken into account. Firstly, the geographical location and local wind speeds are crucial in determining the magnitude of the wind load. Additionally, the exposure category of the site, which defines the terrain and surrounding structures, is important in assessing the wind pressure coefficients. The building height and shape also influence the wind load distribution on the I-beams. Lastly, the material properties, connection details, and the structural design codes and standards must be carefully considered to ensure the I-beams can withstand the anticipated wind forces without failure.

- Q: How do steel I-beams perform in extreme temperature conditions?

- Steel I-beams perform well in extreme temperature conditions. Due to their high thermal conductivity and low coefficient of thermal expansion, they can efficiently dissipate heat and resist deformation caused by temperature fluctuations. This makes them ideal for use in structures that are exposed to extreme heat or cold, such as industrial buildings, bridges, and high-rise constructions.

- Q: What is the difference between hot-rolled and cold-formed steel I-beams?

- The main difference between hot-rolled and cold-formed steel I-beams lies in the manufacturing process. Hot-rolled steel I-beams are formed by heating a steel billet and passing it through a series of rollers at high temperatures. This process gives the steel its characteristic shape and strength, making it ideal for structural applications. On the other hand, cold-formed steel I-beams are formed by bending or rolling cold-rolled steel sheets or strips at room temperature. This process allows for greater precision in terms of dimensions and shapes, making cold-formed steel I-beams suitable for applications where tight tolerances are required. Additionally, hot-rolled steel I-beams generally have a rougher surface finish compared to cold-formed steel I-beams.

- Q: Are steel I-beams resistant to impact or shock loads?

- Generally, steel I-beams are resistant to impact or shock loads. Steel is a durable and strong material that can withstand significant forces, making it ideal for structural applications like I-beams. Steel I-beams can absorb and distribute energy throughout their structure when subjected to impact or shock loads, minimizing the potential for deformation or failure. However, it is important to consider that the resistance to impact or shock loads can vary depending on the dimensions, quality, and design of the steel I-beam. Furthermore, the overall structural integrity of the supporting components and connections must also be taken into account to ensure the I-beam effectively resists impact or shock loads.

- Q: What are the typical spans achievable with steel I-beams?

- The typical spans achievable with steel I-beams can vary depending on various factors such as the beam size and load requirements. However, in general, steel I-beams can achieve spans ranging from a few feet to several hundred feet.

- Q: Is the material of steel I-beam manganese steel?

- Ordinary I-beam, light I-beam flange is variable cross-section, the thickness of the web board, the external thin; H steel: HW, HM, HN, HEA, HEB, HEM and other workersOrdinary I-beam, lightweight I-beam has formed the national standard, the common 10# I-beam is equivalent to the Internet I100 (such as 10# also channel equivalent channel (U100) for the implementation of the standards of different countries, which have subtle differences in their specifications)

- Q: Can steel I-beams be used in architectural designs requiring curved structures?

- Yes, steel I-beams can be used in architectural designs requiring curved structures. While I-beams are typically associated with straight and rigid construction elements, they can be curved to fit the desired shape. This process is achieved through a technique called cold bending, where the beam is gradually bent to the desired radius. The ability to cold bend steel I-beams allows architects and engineers to create unique and visually appealing curved structures that maintain the strength and durability of steel. Additionally, curved I-beams can provide structural advantages by distributing loads more efficiently and reducing the need for additional support elements. However, it is important to consult with structural engineers and steel fabricators to ensure that the curved I-beams meet all necessary design and safety requirements.

- Q: What are the common defects or issues found in steel I-beams?

- Some common defects or issues found in steel I-beams include corrosion, cracks, bending or warping, and improper welding or fabrication. These defects can weaken the structural integrity of the I-beams and compromise their load-bearing capacity. Regular inspections and maintenance are necessary to identify and address these issues promptly to ensure the safety and durability of the steel I-beams.

- Q: How do steel I-beams compare to concrete beams?

- Steel I-beams and concrete beams have different properties and strengths. Steel I-beams are known for their high strength-to-weight ratio, making them ideal for supporting heavy loads over long spans. They are durable, flexible, and can be easily fabricated to meet specific design requirements. Steel I-beams also have excellent resistance against fire and can withstand extreme temperature changes without significant damage. On the other hand, concrete beams are known for their high compressive strength. They are commonly used in construction projects where heavy loads need to be supported vertically. Concrete beams also provide good sound insulation and have a long service life. However, they are heavier compared to steel beams, which may require additional support and foundations. In summary, steel I-beams are preferred when the main concern is strength and flexibility, while concrete beams are suitable for applications where high compressive strength and durability are required. The choice between the two depends on the specific needs and requirements of the construction project.

Send your message to us

Hot Rolled Steel I-Beam For Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords