Hot Rolled Steel I-Beams with Highest Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

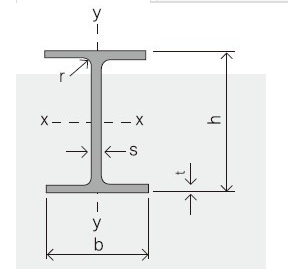

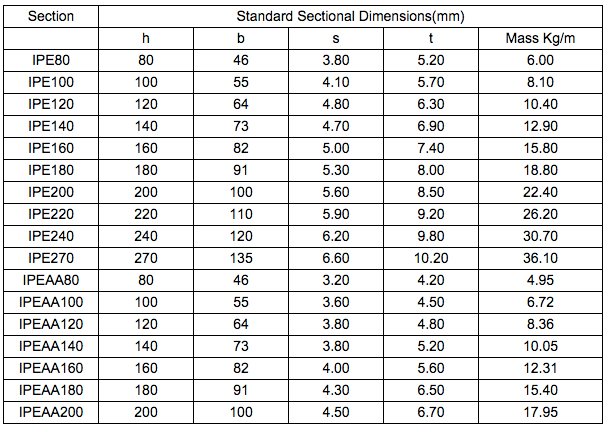

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: The products are invoicing on theoritical weight or on actual weight?

A2: We can do it in both manners, according to the customers' request.

Q3:What's your payment terms ?

A3:Mostly,we collect the money by T/T and LC at sight . We also accept time LC at 90/120 days s

Q4: How do you guarantee the quality of products?

A4: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Images:

- Q: Can steel I-beams be used in water treatment plant construction?

- Indeed, steel I-beams find practical application in the construction of water treatment plants. Renowned for its exceptional durability and strength, steel is a favored material in various construction endeavors, including the establishment of water treatment facilities. Steel I-beams, specifically, are commonly employed for structural reinforcement in both buildings and infrastructure due to their robustness and ability to bear heavy loads. In the context of water treatment plants, where the presence of weighty machinery and structures necessitates reliable support, steel I-beams are frequently employed to ensure the overall stability and integrity of the construction. Furthermore, steel boasts resistance to corrosion, a vital attribute in water treatment plants where the combination of water and chemicals can gradually corrode other materials. Hence, steel I-beams are an ideal choice for constructing water treatment plants, offering the requisite strength, endurance, and corrosion resistance.

- Q: What are the different types of connections used for steel I-beams in seismic areas?

- In seismic areas, steel I-beams commonly use different types of connections to ensure structural stability and prevent damage during earthquakes. Some of the commonly employed connections include bolted connections, welded connections, and moment-resisting connections. Bolted connections involve using bolts to connect the beams to other structural elements, providing flexibility and ease of installation. Welded connections involve fusing the beams together using heat and creating a strong, continuous connection. Moment-resisting connections are designed to resist the rotational forces generated during an earthquake and often utilize a combination of bolts and welds to provide enhanced strength and rigidity. These various types of connections are engineered to meet specific seismic design requirements and ensure the safety and performance of steel I-beam structures.

- Q: What are the potential drawbacks of using steel I-beams?

- When using steel I-beams in construction projects, there are several possible disadvantages to consider. Firstly, the heaviness of steel as a material can significantly increase the overall weight of the structure. This can result in additional costs for transportation and installation, as well as potential limitations on the building's overall design and load-bearing capacity. Secondly, if steel I-beams are not properly protected, they can be vulnerable to corrosion. Exposure to moisture or harsh environmental conditions can cause rusting, which weakens the beams' structural integrity over time. To prevent this issue, regular maintenance and protective coatings are necessary, which can increase the overall cost and effort required for upkeep. Moreover, steel I-beams have a high thermal conductivity, meaning they can easily transfer heat or cold. This can lead to energy inefficiency as heat or cold passes through the beams, requiring additional insulation measures to maintain comfortable indoor temperatures. These insulation requirements can add to the construction costs and potentially impact the building's overall energy efficiency. Lastly, steel production has a significant environmental impact. The extraction and processing of raw materials for steel production can contribute to deforestation, habitat destruction, and greenhouse gas emissions. Additionally, the manufacturing process itself consumes vast amounts of energy and generates substantial carbon emissions. Therefore, the use of steel I-beams may not align with sustainable building practices and environmental goals. In conclusion, while steel I-beams offer excellent strength and durability, it is important to carefully consider the potential drawbacks related to weight, corrosion, thermal conductivity, and environmental impact before deciding to use them in construction projects.

- Q: Can steel I-beams be used in railway or transportation infrastructure?

- Yes, steel I-beams can be used in railway or transportation infrastructure. They are commonly used for constructing bridges, overpasses, and railway tracks due to their strength, durability, and load-bearing capacity. Steel I-beams provide structural support, ensuring the integrity and safety of the transportation infrastructure.

- Q: Can steel I-beams be used for long-span structures?

- Yes, steel I-beams can be used for long-span structures. Steel I-beams are known for their strength and ability to bear heavy loads, making them suitable for long-span structures such as bridges, industrial buildings, and large commercial spaces. The use of steel I-beams allows for the creation of open and spacious areas without the need for intermediate supports. Additionally, steel I-beams can be easily connected and fabricated to create longer spans, providing flexibility in design and construction. The high strength-to-weight ratio of steel also makes it a preferred choice for long-span structures as it allows for lighter structures without compromising on strength and stability. Overall, steel I-beams are widely used in the construction industry for long-span structures due to their durability, strength, and versatility.

- Q: Can steel I-beams be used for rooftop structures or equipment support?

- Yes, steel I-beams can be used for rooftop structures or equipment support. Steel I-beams are known for their strength and load-bearing capabilities, making them a suitable choice for supporting heavy equipment or constructing rooftop structures. They provide excellent structural support and can withstand the weight and stress associated with rooftop installations. Additionally, steel I-beams are durable, long-lasting, and resistant to weather conditions, making them a reliable choice for rooftop applications. However, it is important to ensure that the design and installation are done by professionals to ensure proper load distribution and structural integrity.

- Q: How do steel I-beams compare to reinforced concrete beams in terms of cost and performance?

- Steel I-beams typically have a lower initial cost compared to reinforced concrete beams due to the more efficient manufacturing process. However, reinforced concrete beams offer longer-term cost savings as they require less maintenance and have a longer lifespan. In terms of performance, steel I-beams provide superior strength-to-weight ratio, allowing for longer spans and more flexibility in design. On the other hand, reinforced concrete beams offer better fire resistance and soundproofing properties. Ultimately, the choice between steel I-beams and reinforced concrete beams depends on the specific project requirements, budget, and desired performance characteristics.

- Q: Can steel I-beams be used for roof trusses?

- Yes, steel I-beams can be used for roof trusses. Steel I-beams are commonly used in construction due to their strength and durability. When used as roof trusses, they provide excellent support and stability to the roof structure. Steel I-beams are capable of withstanding heavy loads and can span longer distances compared to other materials such as wood. Additionally, steel I-beams are resistant to rot, pests, and fire, making them a reliable choice for roof trusses. However, it is important to ensure that the design and installation of steel I-beams for roof trusses meet local building codes and regulations to ensure proper structural integrity and safety.

- Q: Can steel I-beams be used for military structures?

- Yes, steel I-beams can be used for military structures. Steel I-beams are commonly used in construction due to their high strength and durability. These qualities make them suitable for various military applications such as barracks, hangars, command centers, and other infrastructure. Steel I-beams provide structural stability and can withstand heavy loads, making them ideal for military structures that may need to withstand extreme weather conditions or potential attacks. Additionally, steel I-beams can be easily fabricated and assembled, allowing for quick deployment of military structures in various locations.

- Q: Can Steel I-Beams be used for food processing facilities?

- Yes, Steel I-Beams can be used for food processing facilities. Steel I-Beams are commonly used in various industrial applications due to their strength, durability, and load-bearing capabilities. In food processing facilities, where heavy machinery and equipment are often present, Steel I-Beams can provide the necessary structural support. Additionally, steel is resistant to corrosion, which is crucial in food processing environments where hygiene and cleanliness are of utmost importance. The versatility of Steel I-Beams also allows for flexible design options, ensuring that the facility can be customized to meet specific requirements. Overall, Steel I-Beams are an excellent choice for food processing facilities due to their strength, durability, corrosion resistance, and versatility.

Send your message to us

Hot Rolled Steel I-Beams with Highest Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords