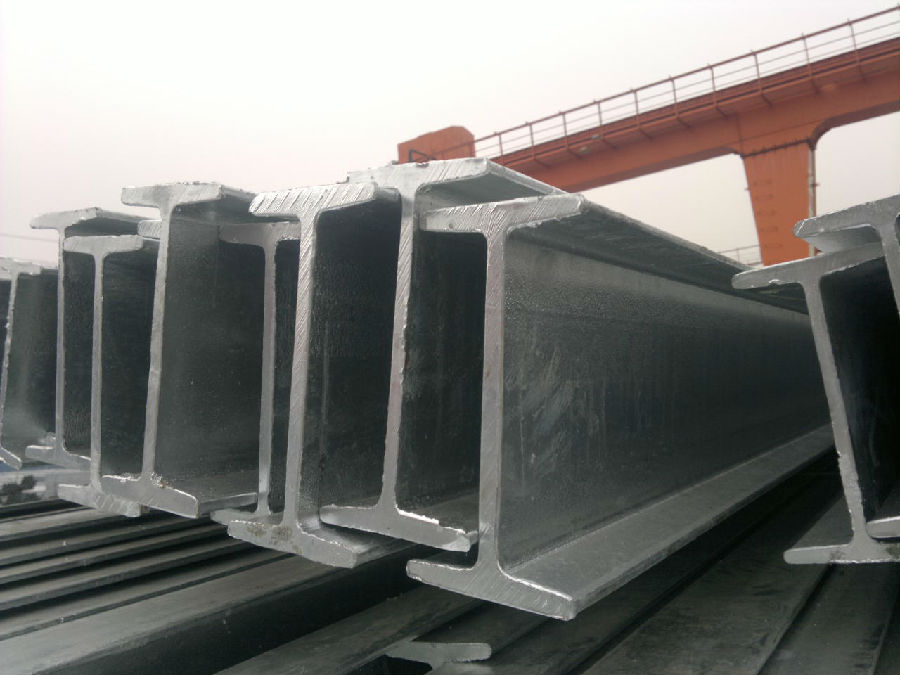

BS Standard Structural Steel I-Beam

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 200000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality BS Standard Structural Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

BS Standard Structural Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: SS400, ST37-2, A36, S235 JRG1, Q235, Q345

Standard: BS, JIS, ASTM, DIN, EN, GB/T 700-1988

Certificates: ISO, SGS, BV, CIQ

Dimensions:

Chinese Standard: 100*68*4.5mm, 630*180*17mm

European Standard: 80*46*3.8mm, 600*220*12mm

Length: 6m, 9m, 12m

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel I-beams be customized or fabricated to specific lengths or dimensions?

- Yes, steel I-beams can be customized or fabricated to specific lengths or dimensions. Steel fabrication companies have the capability to cut, bend, and weld the beams to meet the required specifications. This allows for a wide range of customization options, enabling the beams to be tailored to fit specific project requirements. Whether it is for construction, infrastructure, or other applications, steel I-beams can be fabricated to precise lengths and dimensions to ensure optimal performance and structural integrity.

- Q: How do you inspect steel I-beams for defects?

- Inspecting steel I-beams for defects involves a systematic approach to ensure the structural integrity and safety of the beams. Here are the steps typically followed in inspecting steel I-beams for defects: 1. Visual Inspection: Begin by visually examining the entire surface of the steel I-beams. Look for any signs of cracks, corrosion, or damages such as deformations, dents, or buckling. Pay special attention to areas where there may be joints or connections, as these are more prone to defects. 2. Non-Destructive Testing (NDT): Utilize non-destructive testing methods to identify defects that may not be visible to the naked eye. Common NDT methods include ultrasonic testing (UT), magnetic particle testing (MT), liquid penetrant testing (PT), and radiographic testing (RT). These techniques help detect internal flaws, cracks, and other defects that could compromise the structural integrity of the I-beams. 3. Ultrasonic Testing: This method utilizes high-frequency sound waves to detect internal defects such as cracks or voids in the steel. A specialized device called an ultrasonic flaw detector is used to send sound waves through the beam. Any disruptions in the sound waves' pattern can indicate the presence of defects. 4. Magnetic Particle Testing: This technique is particularly effective for identifying surface and near-surface defects. A magnetic field is applied to the steel I-beam, and iron particles are applied to the surface. If there are any defects, the particles will gather at these locations due to magnetic attraction, making the defects visible. 5. Liquid Penetrant Testing: This method involves applying a liquid penetrant to the surface of the I-beam. The penetrant seeps into any surface defects and is then wiped off. A developer is applied, causing the penetrant to bleed out and reveal the presence of defects. 6. Radiographic Testing: In this method, X-rays or gamma rays are passed through the steel I-beam, and an image is captured on a film or digital detector. Any internal defects, such as cracks or voids, will show up as dark spots or irregularities on the image. 7. Documentation: It is crucial to document all findings during the inspection process. Record any defects, their locations, sizes, and severity. This documentation helps in determining the necessary repairs or replacements required to maintain the structural integrity of the steel I-beams. It is important to note that the inspection of steel I-beams for defects should be conducted by qualified and experienced professionals who are knowledgeable in the specific inspection methods and techniques.

- Q: Are there any building codes or regulations that govern the use of steel I-beams in construction?

- Yes, there are building codes and regulations that govern the use of steel I-beams in construction. These codes and regulations ensure that the design, fabrication, and installation of steel I-beams adhere to certain safety standards. They cover aspects such as material strength, structural integrity, and load-bearing capacity, ensuring the overall safety and stability of the building. Compliance with these codes is necessary to obtain building permits and ensure the structural soundness of the construction project.

- Q: How can I spray the fluorocarbon paint on the bottom of I-beam?

- Then primer, general primer with two-component epoxy primer, or epoxy zinc rich primer, primer can enhance adhesion, has a strong rust resistance.

- Q: Can steel I-beams be used for retail buildings?

- Yes, steel I-beams can be used for retail buildings. Steel I-beams are commonly used in commercial construction, including retail buildings, due to their strength and load-bearing capabilities. They provide structural support, allowing for larger open spaces and flexible layouts in retail spaces.

- Q: How do steel I-beams compare to timber beams in terms of strength?

- Steel I-beams are generally stronger than timber beams in terms of strength. Steel has a much higher strength-to-weight ratio compared to timber, allowing steel I-beams to support greater loads without sagging or bending. Additionally, steel is more resistant to compression, tension, and bending forces, making it a more reliable choice for structural support. Timber beams, on the other hand, can be prone to warping, splitting, and decay over time, which can compromise their strength. However, it is important to note that the strength of steel I-beams can vary depending on the specific grade and size of the beam, while timber beams can be reinforced with additional members or materials to enhance their strength.

- Q: How do steel I-beams handle lateral loads, such as wind or earthquakes?

- Steel I-beams have been purposely designed to effectively withstand lateral loads, such as wind or earthquakes. The I-shaped cross-section of these beams imparts exceptional structural strength and rigidity, making them ideal for withstanding horizontal forces acting perpendicular to their length. Regarding wind loads, the shape of the I-beam aids in evenly distributing the force along its length, thereby minimizing the likelihood of localized failure. The top and bottom flanges of the beam are specifically engineered to resist bending moments and shear forces, while the web, connecting the flanges, facilitates load transfer between them. By combining these components, an efficient load-carrying system is achieved, effectively countering lateral forces produced by wind. Similarly, when confronted with earthquakes, steel I-beams demonstrate their aptitude in handling resultant lateral ground movements. The inherent stiffness of steel, in conjunction with the I-beam's shape, allows for dissipation of seismic energy through flexion and deformation rather than collapse. The I-beam's ability to distribute the load uniformly along its entire length diminishes concentrated stress at any particular point, thus rendering it more resistant to seismic events. To further enhance the capacity of I-beams to handle lateral loads, engineers may incorporate additional design features. These may encompass bracing systems, such as diagonal or cross-bracing, which further fortify the beam against lateral forces. Additionally, ensuring comprehensive load paths and augmenting overall structural integrity can be achieved by appropriately fastening and connecting the I-beams to other structural elements, such as columns and foundations. In summary, steel I-beams possess the requisite strength, shape, and capacity to distribute and dissipate forces, making them highly suitable for handling lateral loads like wind or earthquakes. Consequently, they are frequently favored in construction projects where resilience against these types of loads is imperative.

- Q: Are there any health or safety concerns associated with steel I-beams?

- Yes, there are potential health and safety concerns associated with steel I-beams. These concerns primarily revolve around the handling and installation process. Steel I-beams are heavy and require proper lifting equipment and techniques to prevent accidents and injuries. Additionally, workers need to be cautious of sharp edges and corners that can cause cuts and bruises. It is crucial to follow safety protocols and wear personal protective equipment to mitigate these risks.

- Q: What are the common accessories used with steel I-beams, such as brackets and connectors?

- Common accessories used with steel I-beams include brackets, connectors, cleats, hangers, bolts, and plates. These accessories are essential for providing structural support, connecting beams together, securing them to other components, and ensuring the overall stability and integrity of the I-beam structure.

- Q: Can steel I-beams be used in the construction of bridges?

- Yes, steel I-beams can be used in the construction of bridges. They are commonly used due to their high strength-to-weight ratio, durability, and ability to span long distances without the need for additional support.

Send your message to us

BS Standard Structural Steel I-Beam

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 200000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords