Mild Steel Double T Equivalent to I Beam Steel in Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Mild Steel Double T Equivalent to I Beam Description:

Mild steel double T equivalent to I beam is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Mild steel double T equivalent to I beam is usually made of structural steel and is used in construction and civil engineering. The mild steel double T equivalent to I beam resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Mild steel double T equivalent to I beam theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam Bar IPE Images:

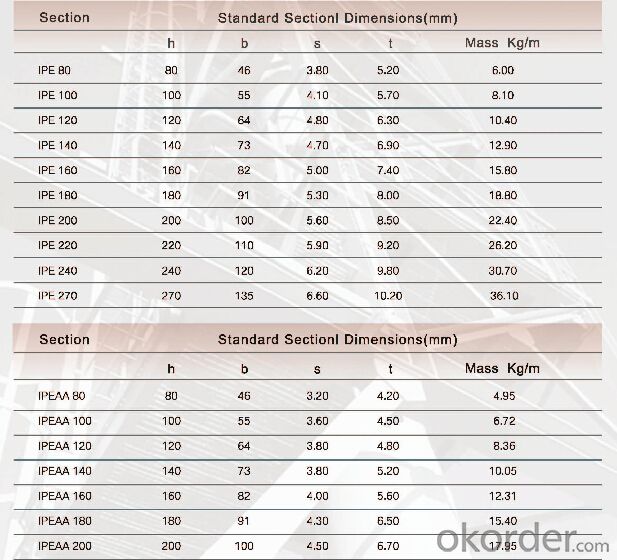

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: How do steel I-beams perform in seismic regions?

- Steel I-beams perform well in seismic regions due to their inherent strength and ductility. The flexible nature of steel allows it to absorb and dissipate seismic energy, reducing the risk of structural failure during earthquakes. Additionally, I-beams are designed with a wide flange and deep section, providing enhanced resistance to lateral forces and increasing their stability in seismic events.

- Q: How are steel I-beams used in commercial construction?

- Steel I-beams are commonly used in commercial construction due to their strength, versatility, and cost-effectiveness. These beams are typically made of high-quality steel and are shaped like the letter "I," with a horizontal top flange, a vertical web in the middle, and another horizontal bottom flange. In commercial construction, steel I-beams are primarily used as structural components to support the weight of the building and transfer loads to the foundation. They are commonly used for constructing floors, roofs, and walls, as well as in the framework of bridges and other large structures. One of the main advantages of steel I-beams is their ability to span long distances while supporting heavy loads. The shape of the I-beam provides excellent strength-to-weight ratio, allowing it to carry significant loads without excessive weight. This makes it possible to create large open spaces within commercial buildings, such as warehouses, shopping centers, and industrial facilities, without the need for additional columns or supports. Steel I-beams also offer flexibility in design and construction. They can be customized to meet specific structural requirements, such as the desired span, load capacity, and overall design aesthetics. This adaptability allows architects and engineers to create efficient and functional commercial spaces while ensuring structural integrity. Additionally, steel I-beams are highly durable and resistant to fire, corrosion, and pests, making them suitable for long-term use in commercial buildings. They require minimal maintenance compared to other construction materials, reducing overall lifecycle costs. In summary, steel I-beams are essential components in commercial construction due to their strength, versatility, and cost-effectiveness. They provide structural support, enable the creation of large open spaces, and offer design flexibility. Their durability and low maintenance requirements make them an ideal choice for long-lasting and efficient commercial buildings.

- Q: The tunnel arch sprayed concrete I-beam to dismantle after?

- I-steel and arch initial support is not removed.But if the temporary arch by CD method or CRD method need to be removed.

- Q: Can steel I-beams be used for cryogenic applications?

- Indeed, cryogenic applications can make use of steel I-beams. The remarkable strength and durability of steel render it a fitting choice for a multitude of industrial uses, including those in cryogenic settings. Nonetheless, it is crucial to exercise caution when selecting the precise variant of steel to guarantee its aptitude in enduring the extreme temperatures and potential brittleness that can manifest under cryogenic circumstances. Moreover, it is imperative to consider adequate insulation and design factors in order to reduce heat transfer and avert thermal strain on the steel beams.

- Q: What is the material of hot rolled ordinary I-beam?

- Hot rolled ordinary I-beam is Q235 material, that is the original "A3" steel.

- Q: How do steel I-beams perform in high humidity environments?

- Steel I-beams are generally known for their strength and durability, and they perform well in high humidity environments. However, prolonged exposure to high humidity can have some potential effects on steel I-beams. One of the primary concerns in high humidity environments is the possibility of corrosion. When steel is exposed to moisture, especially in the presence of oxygen, it can react and form rust, which weakens its structural integrity. In areas with consistently high humidity, the risk of corrosion may be higher. To mitigate the effects of humidity on steel I-beams, several measures can be taken. Firstly, the steel can be coated with protective coatings such as paint or galvanization. These coatings act as a barrier against moisture and help prevent corrosion. Regular inspection and maintenance are also essential to identify and address any signs of corrosion before they worsen. Additionally, proper ventilation and humidity control within the environment can help minimize the risk of moisture accumulation on the surface of steel I-beams. By maintaining relative humidity levels within recommended ranges, the likelihood of corrosion can be significantly reduced. Overall, while steel I-beams are generally reliable in high humidity environments, it is crucial to implement protective measures and maintenance practices to ensure their long-term performance and structural integrity.

- Q: What is the modulus of elasticity of No. 16 I-beam?

- When the material is in the elastic deformation stage, its stress and strain should be changed into a positive proportion (that is to say, according to Hooke's law), and the coefficient of proportionality is called the elastic modulus. The elastic modulus of the unit is dyne per square centimeter. "Modulus of elasticity" is a physical quantity describing the elasticity of matter. It is a general term. It can be expressed as "Young's modulus", "shear modulus", "bulk modulus" and so on.

- Q: How do steel I-beams perform in high-traffic bridge applications?

- Due to their exceptional strength and durability, steel I-beams are an excellent option for high-traffic bridge applications. These beams are specifically engineered to withstand heavy loads and offer superior structural support, making them ideal for use in bridges experiencing high volumes of traffic. A key advantage of steel I-beams is their ability to carry heavy loads. They can withstand the weight of multiple vehicles simultaneously, ensuring the safety and stability of the bridge, even under extreme traffic conditions. Not only are steel I-beams strong, but they also possess long-term durability. They are highly resistant to corrosion, rust, and other environmental factors, enabling their use in various climates and locations. This durability ensures that the bridge remains structurally sound and can endure the wear and tear caused by continuous traffic flow. Moreover, the design of steel I-beams allows for efficient weight distribution, reducing the strain on the bridge structure. This efficient load distribution helps minimize deflection and deformation, guaranteeing the bridge's integrity over time. Another advantage of steel I-beams is their versatility in bridge construction. They can be easily fabricated and tailored to meet the specific requirements of each bridge project, including length, width, and height. This flexibility empowers engineers to design bridges that can accommodate different traffic conditions, ensuring optimal performance and safety. Overall, steel I-beams are a highly reliable and efficient choice for high-traffic bridge applications. Their strength, durability, and versatility make them the preferred option for engineers and architects when designing bridges capable of handling heavy traffic loads and providing long-lasting performance.

- Q: Can steel I-beams be used for temporary support during renovations or repairs?

- Yes, steel I-beams can be used for temporary support during renovations or repairs. Steel I-beams are known for their strength and load-bearing capabilities, making them ideal for providing temporary support to structures during construction or repair work. They are commonly used to support walls, ceilings, and floors, ensuring the safety and stability of the building. However, it is important to consult with a structural engineer or a professional contractor to determine the appropriate size and type of steel I-beam needed to support the specific load requirements of the project.

- Q: What's the difference between I-beam and H section steel?

- Flange type H steel is flat, no change in the thickness, and the flange steel is from the root to the edge gradually thinning, have a certain angle, it is significant to distinguish them. In addition, the model is Arabia digital I-beam with its waist high cm to said, met with the waist high the models in the A, B, C to distinguish, such as 20a, 20b, 32c, the former two waist height is 20cm, and the web, flange thickness and different width of flange;

Send your message to us

Mild Steel Double T Equivalent to I Beam Steel in Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords